Wood machining device

A processing device and wood technology, applied to wood processing equipment, manufacturing tools, bark, etc., can solve problems such as uneven force, trouble, and incomplete circulation of wood, and achieve the effect of smooth removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Further detailed explanation through specific implementation mode below:

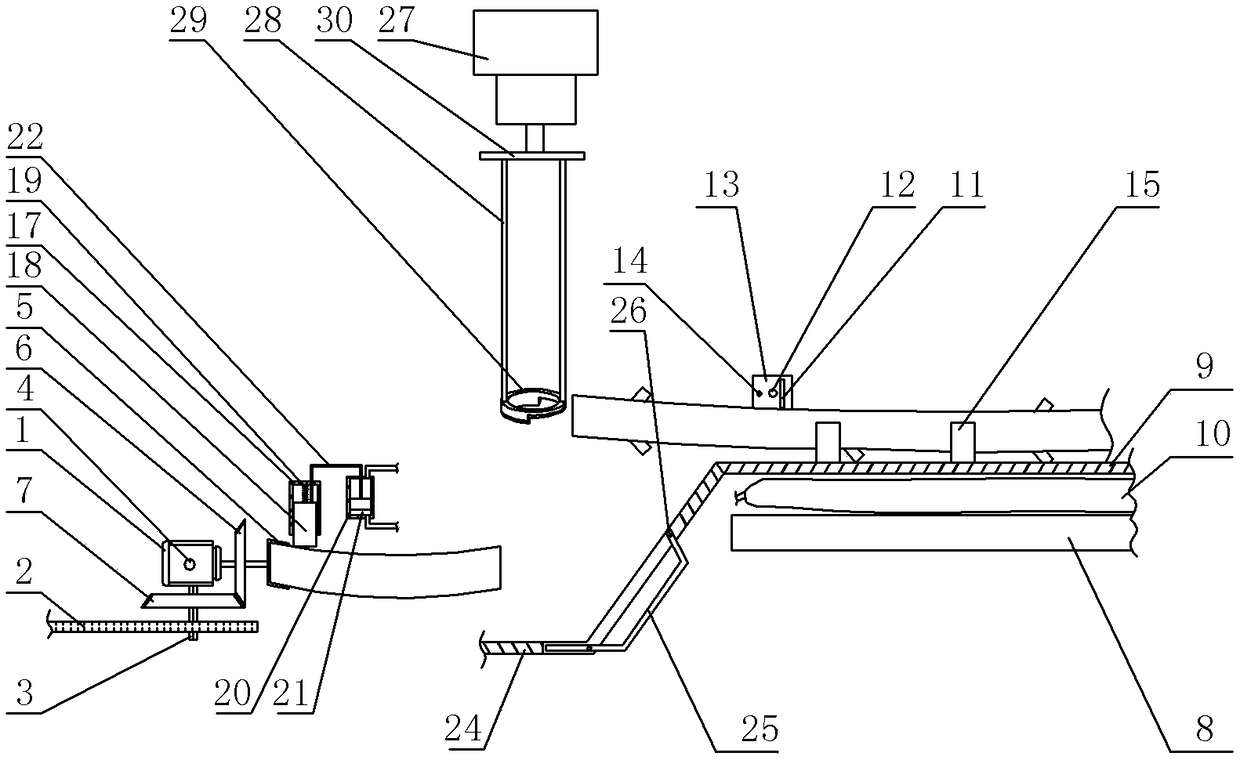

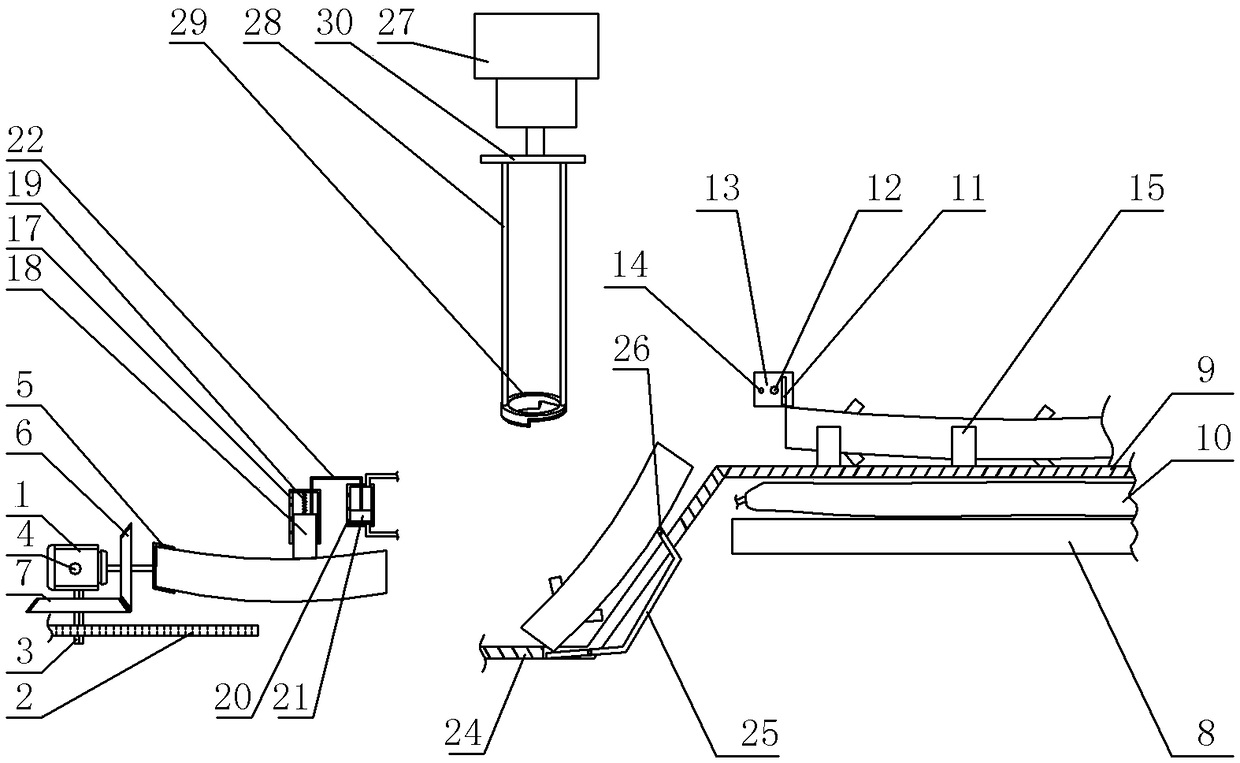

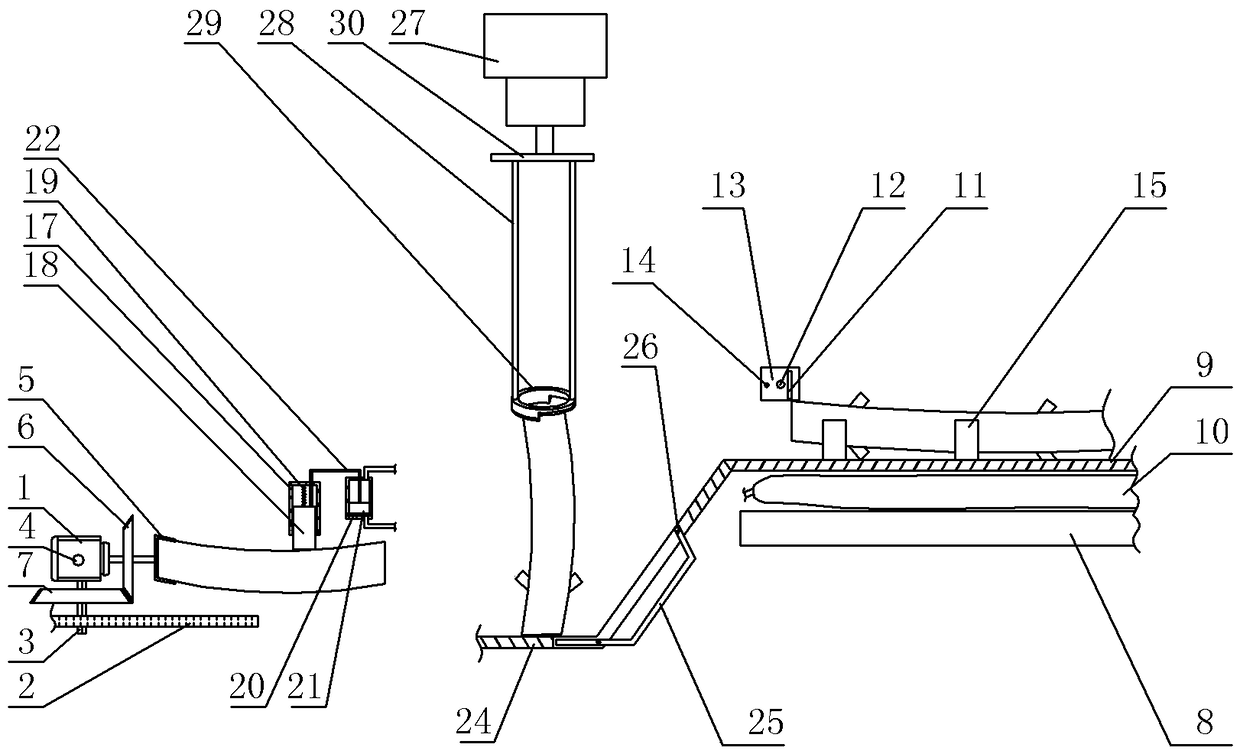

[0024] The reference signs in the accompanying drawings of the description include: the second servo motor 1, the rack 2, the gear rod 3, the support rod 4, the clamping claw 5, the first bevel gear 6, the second bevel gear 7, the support platform 8, the support Plate 9, air bag 10, cutting saw 11, screw rod 12, nut seat 13, limit rod 14, limit plate 15, first servo motor 16, slide rail 17, peeling knife 18, spring 19, pipe body 20, piston 21 , connecting rod 22, the second delimbing edge 23, receiving plate 24, vertical turning bar 25, arc block 26, cylinder 27, stamping bar 28, delimbing knife 29, stamping plate 30, the first delimming edge 31.

[0025] Such as figure 1 In the wood processing device shown, a cutting mechanism, a delimbing mechanism, a peeling mechanism and a transfer mechanism are sequentially arranged on the frame from right to left.

[0026] The transfer mechanism includes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com