Storage mechanical arm capable of counting materials and working method thereof

A technology of manipulators and materials, applied in the field of intelligent manipulators, can solve the problems that the manipulators can't store materials well, can't weigh, count and classify materials, and materials are easy to accumulate dust and damage, so as to achieve convenient storage and output. Library, eliminate inertia and sliding, avoid the effect of rubbing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

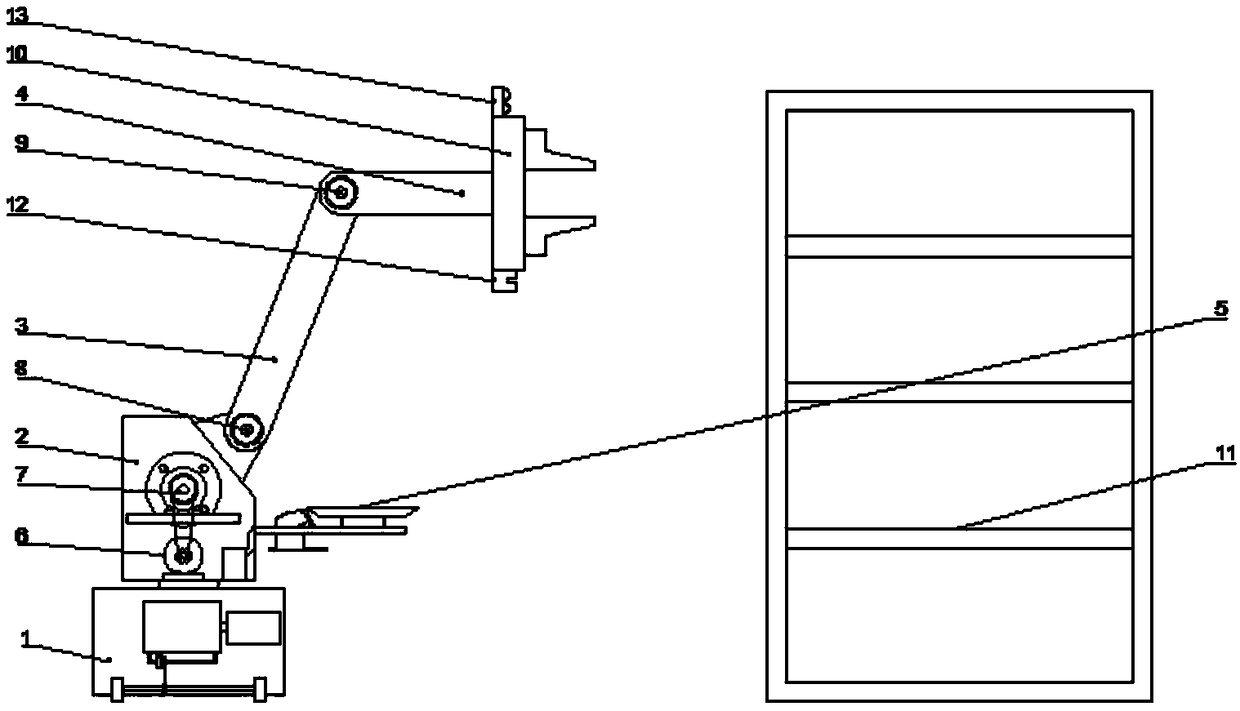

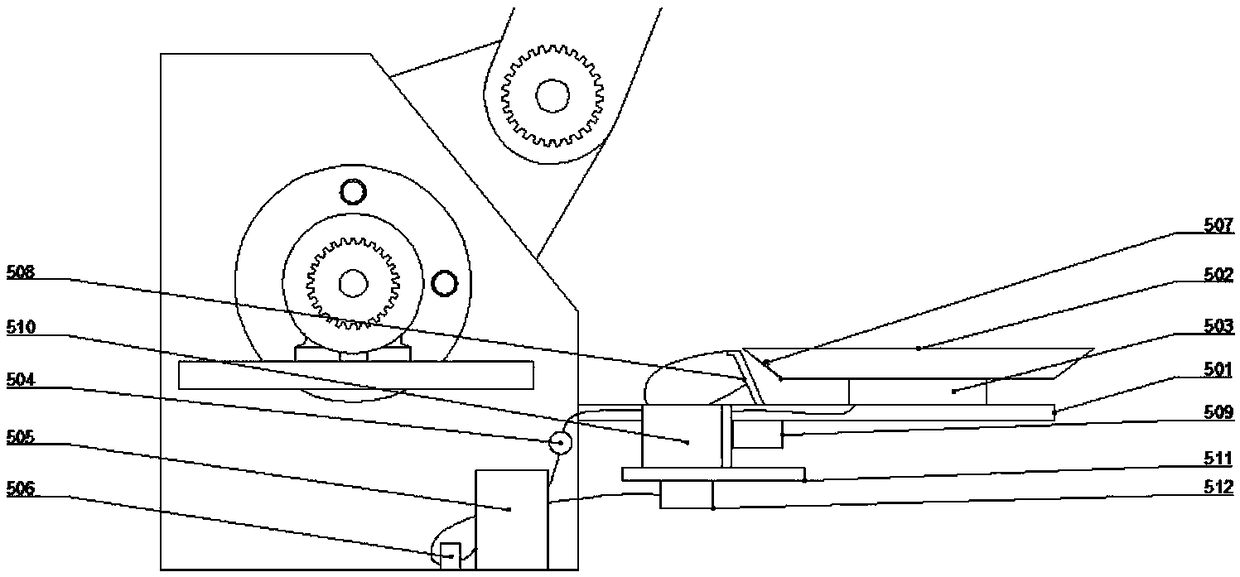

[0053] Such as figure 1 A storage robotic arm for counting materials is shown, including: slide rail base 1, rotating base 2, first robotic arm 3, second robotic arm 4, weighing platform 5, drive motor 6, transmission gear box 7 , The first rotating sprocket set 8, the second rotating sprocket set 9, the electromagnetic chuck 10 and the material storage rack 11, the slide rail base 1 is provided with a rotating base 2 on the rotating base 2 There is a first mechanical arm 3, the rotating base 2 is hinged with a first mechanical arm 3, one end of the first mechanical arm 3 is provided with a second mechanical arm 4, the first mechanical arm 3 and the second mechanical arm 4 Articulated, the second mechanical arm 4 is provided with an electromagnetic chuck 10 at one end; a first rotating sprocket set 8 is provided at the hinge joint of the rotating base 2 and the first mechanical arm 3. The first mechanical arm 3 and the first mechanical arm 3 A second rotating sprocket 9 is arra...

Embodiment 2

[0073] Such as figure 2 A storage robotic arm for counting materials is shown, including: slide rail base 1, rotating base 2, first robotic arm 3, second robotic arm 4, weighing platform 5, drive motor 6, transmission gear box 7 , The first rotating sprocket set 8, the second rotating sprocket set 9, the electromagnetic chuck 10 and the material storage rack 11, the slide rail base 1 is provided with a rotating base 2 on the rotating base 2 There is a first mechanical arm 3, the rotating base 2 is hinged with a first mechanical arm 3, one end of the first mechanical arm 3 is provided with a second mechanical arm 4, the first mechanical arm 3 and the second mechanical arm 4 Articulated, the second mechanical arm 4 is provided with an electromagnetic chuck 10 at one end; a first rotating sprocket set 8 is provided at the hinge joint of the rotating base 2 and the first mechanical arm 3. The first mechanical arm 3 and the first mechanical arm 3 A second rotating sprocket 9 is arr...

Embodiment 3

[0077] Such as image 3 A storage robotic arm for counting materials is shown, including: slide rail base 1, rotating base 2, first robotic arm 3, second robotic arm 4, weighing platform 5, drive motor 6, transmission gear box 7 , The first rotating sprocket set 8, the second rotating sprocket set 9, the electromagnetic chuck 10 and the material storage rack 11, the slide rail base 1 is provided with a rotating base 2 on the rotating base 2 There is a first mechanical arm 3, the rotating base 2 is hinged with a first mechanical arm 3, one end of the first mechanical arm 3 is provided with a second mechanical arm 4, the first mechanical arm 3 and the second mechanical arm 4 Articulated, the second mechanical arm 4 is provided with an electromagnetic chuck 10 at one end; a first rotating sprocket set 8 is provided at the hinge joint of the rotating base 2 and the first mechanical arm 3. The first mechanical arm 3 and the first mechanical arm 3 A second rotating sprocket 9 is arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com