Aluminum gusset plate continuous roller coating equipment

A technology of aluminum buckle plate and roll coating, which is applied in metal processing equipment, grinding/polishing equipment, coating, etc., can solve the problem of uneven roll coating, unsatisfactory roll coating effect, and slow production efficiency on the roll coating surface To achieve the effect of improving the effect of roller coating, saving labor costs and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

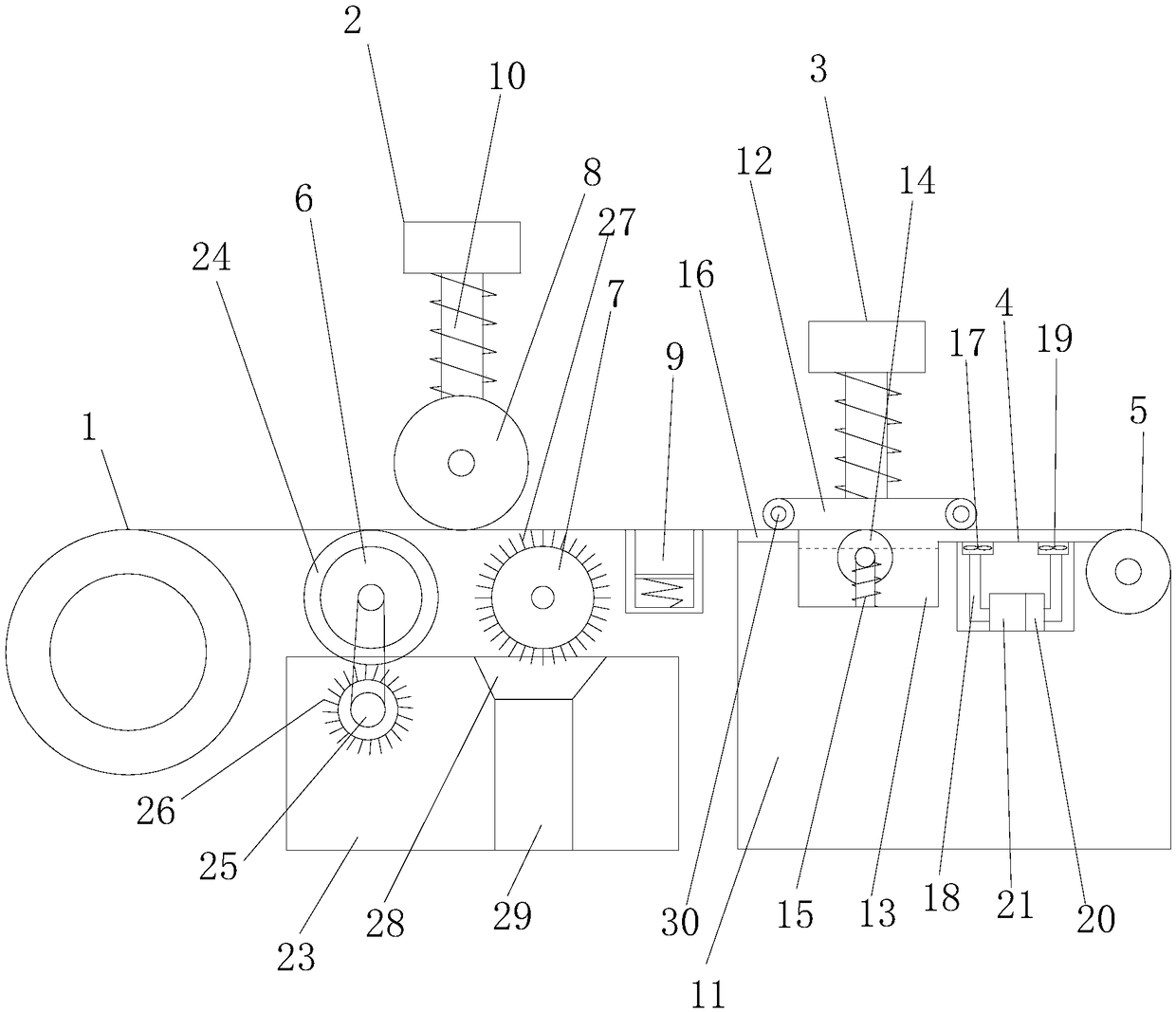

[0012] refer to figure 1 , a kind of continuous roller coating equipment for aluminum gusset plate of the present invention, comprises feeder 1, coating surface cleaning device 2, positioning roller coating device 3, coating surface shaping device 4, material receiving device 5, and the right side of described feeding device 1 A coated surface cleaner 2 is provided, and the coated surface cleaner 2 includes a coated surface grinding roller 6, a coated surface dedusting roller 7, an upper extrusion roller 8, and a dust filter tank 9. The right side of the coated surface grinding roller 6 is provided with Coated surface dedusting roller 7, described coated surface grinding roller 6 and coated surface dedusting roller 7 are arranged parallel to each other on the same horizontal plane, and the gap between the coated surface grinding roller 6 and the coated surface dedusting roller 7 is provided with an upper extrusion Pressure roller 8, the top of the upper squeeze roller 8 is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com