Device used for testing puncture resistance of safety shoes and capable of simulating real situation

A testing device, a technology for safety shoes, applied to the measuring device of the foot or shoe last, the measuring device, the use of applying stable tension/pressure to test the strength of the material, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

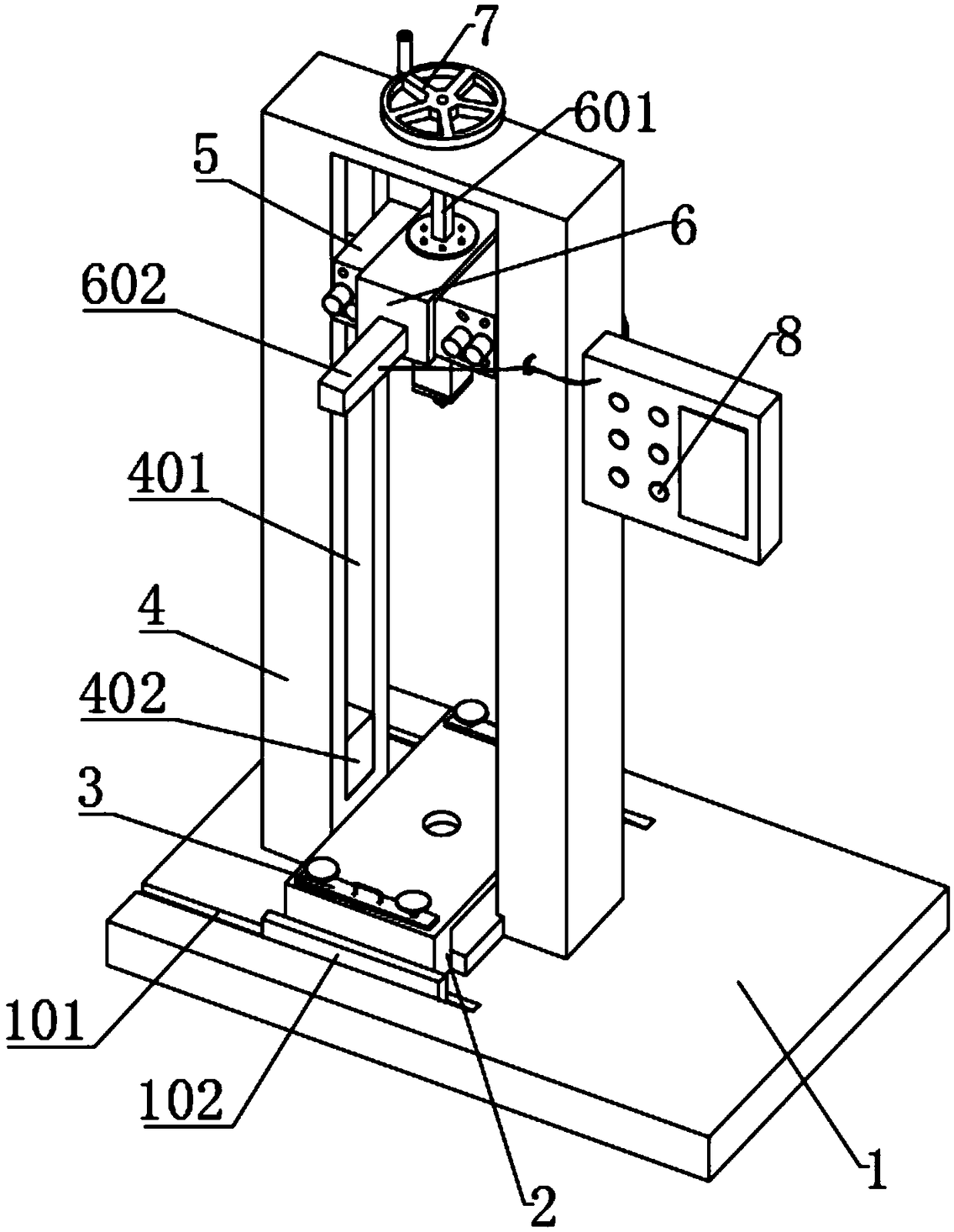

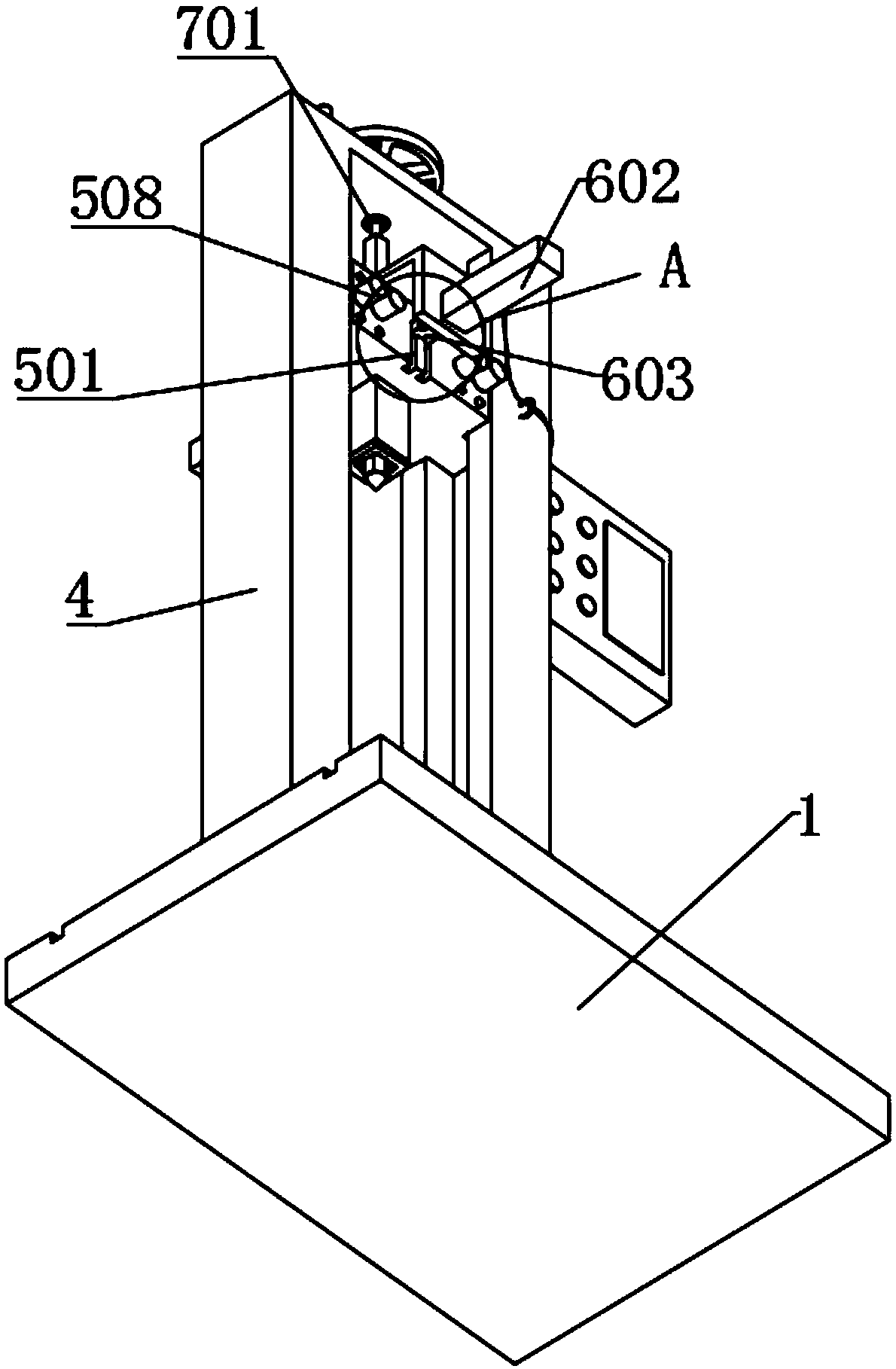

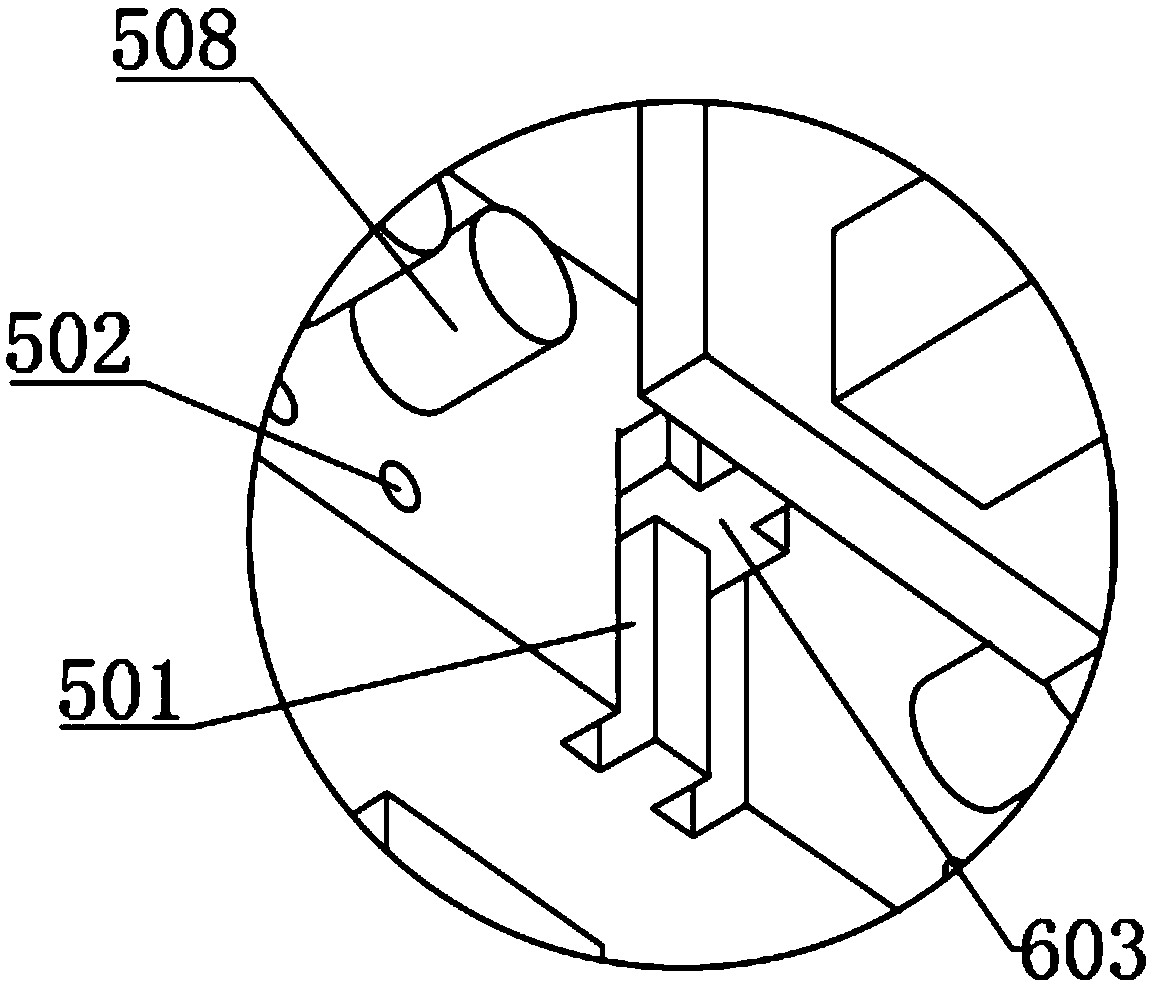

[0037] as attached figure 1 to attach Figure 9 Shown:

[0038]The present invention provides a puncture resistance test device for safety shoes that can simulate real situations, including a base plate 1, a limit groove 101, a limit slide plate 102, a test frame 2, a cavity 201, a puncture hole 202, a threaded connection hole 203, and a plug plate 204, pressing plate 3, through hole 301, hand wheel screw 302, pressing block 303, support column 4, chute 401, rubber buffer block 402, slot 403, puncture test pressing block 5, card slot 501, counterweight threaded hole 502 , guide block 503, bottom column 504, rubber buffer frame 505, thorn screw hole 506, thorn 507, counterweight column 508, clamp frame 6, adjustment column 601, electric cylinder 602, U-shaped block 603, adjustment thread hole 604, adjusting screw 7, bearing 701 and control switch 8; the test frame 2 is inserted into the slot 403 inside the bottom end of the support column 4 through the insert plate 204 and is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com