Silicon composite oxide for negative electrode material of lithium secondary battery and preparation method thereof

A composite oxide and lithium secondary battery technology, which is applied in the direction of secondary batteries, electrode manufacturing, battery electrodes, etc., can solve the problems of reduced capacity retention rate, reduced battery capacity, and reduced slurry stability, so as to improve capacity Effects of promotion rate, capacity improvement, and charge/discharge capacity improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] Preparation of Si-MgSiO 3 -SiO x -C-based silicon composite oxide

[0062] Step (1): Add 8kg of silicon powder with an average particle size of 20μm and 16kg of silicon dioxide powder with an average particle size of 20nm into 50kg of water, stir for 12 hours, mix well, and dry at 200°C for 24 hours to form a raw material Powder mix.

[0063] Step (2): Put 2kg of the raw material powder mixture and metal magnesium into crucible A and crucible B of the vacuum reactor respectively, depressurize to 0.1 torr, then heat, raise the temperature of crucible A to 1500°C, and the crucible B was heated to 900°C and reacted for 5 hours.

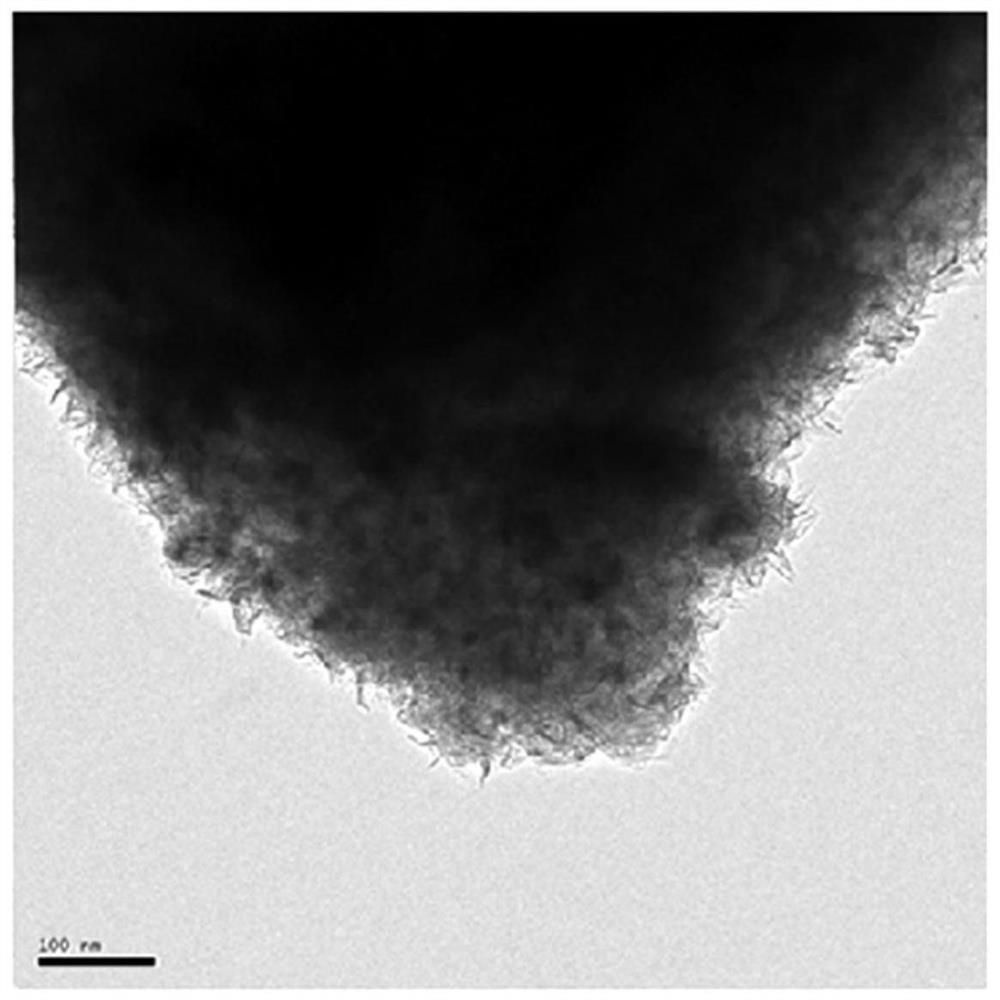

[0064] Step (3): The mass of silicon composite oxide deposited on the substrate inside the reactor through the reaction in the high-temperature gas phase is rapidly cooled to room temperature through the water-cooled substrate.

[0065] Step (4): In order to control the particle size, the silicon composite oxide block is mechanically crush...

experiment example

[0076] X-ray diffraction pattern analysis

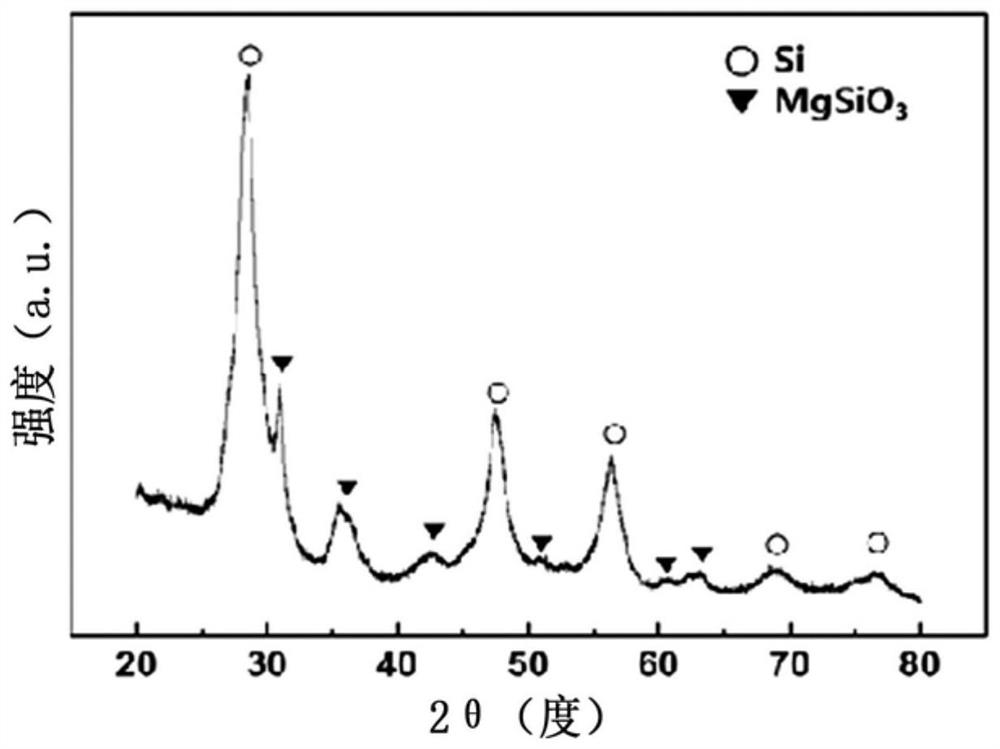

[0077] In order to analyze the crystal structure of the silicon composite oxide prepared in the above-mentioned embodiment 1, its X-ray diffraction pattern was analyzed, and the results are shown in figure 2 .

[0078] Such as figure 2As can be seen in the X-ray diffraction pattern, the peak attributable to Si crystal appears around the diffraction angle (2θ) 28.5°, and the peak attributable to MgSiO appears near the diffraction angle (2θ) 31.0° 3 Crystal peak, thus it can be seen that the silicon composite oxide prepared in Example 1 of the present invention is composed of crystalline Si and MgSiO 3 composition.

[0079] In addition, if figure 2 As seen in the X-ray diffraction diagram of the silicon composite oxide, it can be known from the content of each element component in the silicon composite oxide that it also contains amorphous silicon oxide (SiO x ) and carbon.

[0080] The Si crystal size (crystal size) in the ...

Embodiment 2

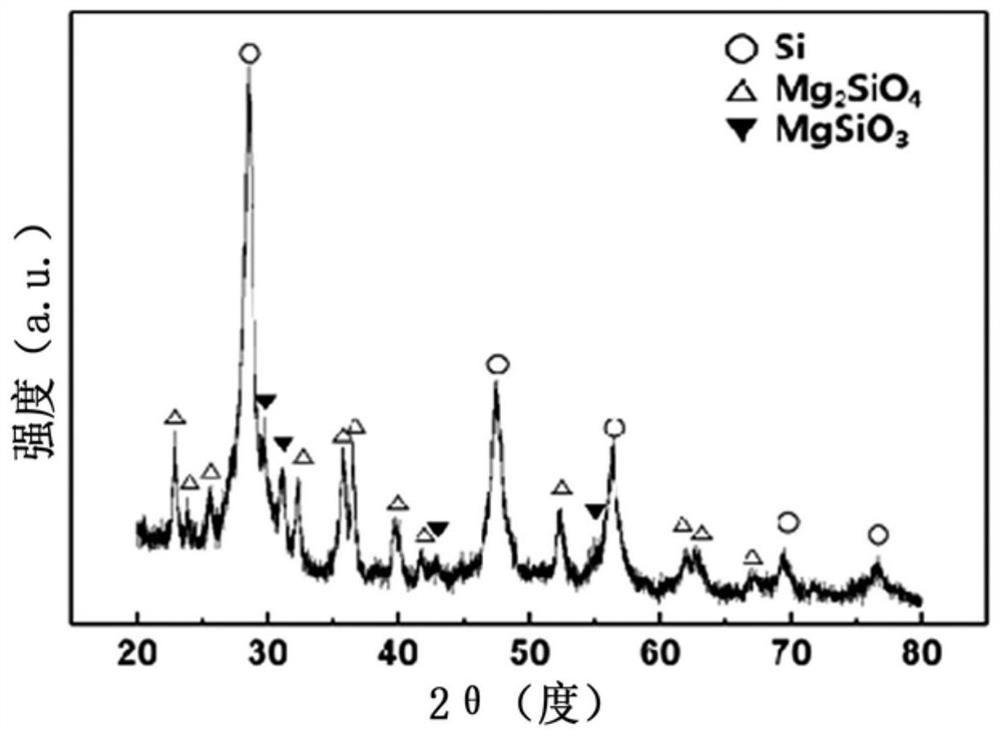

[0083] Preparation of Si-MgSiO 3 -Mg 2 SiO 4 -SiOx-C silicon composite oxide

[0084] The silicon composite oxide powder was prepared by the same method as in the above-mentioned Example 1, except that the silicon composite oxide bulk deposited on the substrate in the above-mentioned Example 1 was naturally cooled with a substrate without water cooling.

[0085] Content analysis of component elements

[0086] The contents of magnesium, oxygen, and carbon in the silicon composite oxide prepared in the above-mentioned Example 2 were analyzed.

[0087] After analysis, the Mg content in the silicon composite oxide is 10wt%, which is analyzed by ICP emission spectrometry, and the content of O and C is 30wt% and 5wt%, which is analyzed by an elemental analyzer. In addition, the specific gravity is 2.6, which is analyzed by a powder pycnometer. After analysis, its value is greater than the specific gravity of SiO (2.2) and less than that of MgSiO 3 Specific gravity (2.7) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com