Ultra-soft low-resistance transparent conductive film and preparation method thereof

A technology of transparent conductive film and conductive network, which is applied to equipment for manufacturing conductive/semiconductive layers, cable/conductor manufacturing, conductive layers on insulating carriers, etc., and can solve the problem of surface resistance and light transmittance of transparent conductive films Integrating poor performance and other issues, it achieves the effects of low surface resistance, high surface flatness, and excellent flex resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

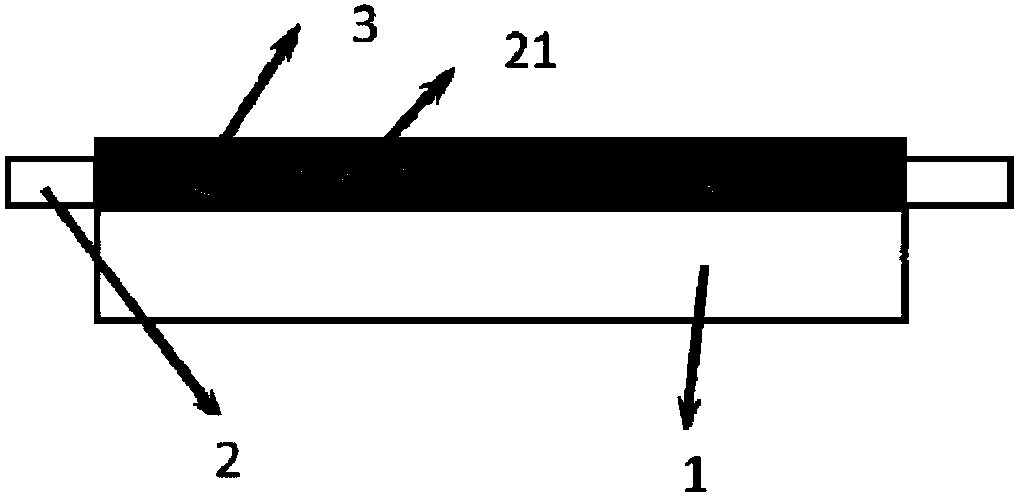

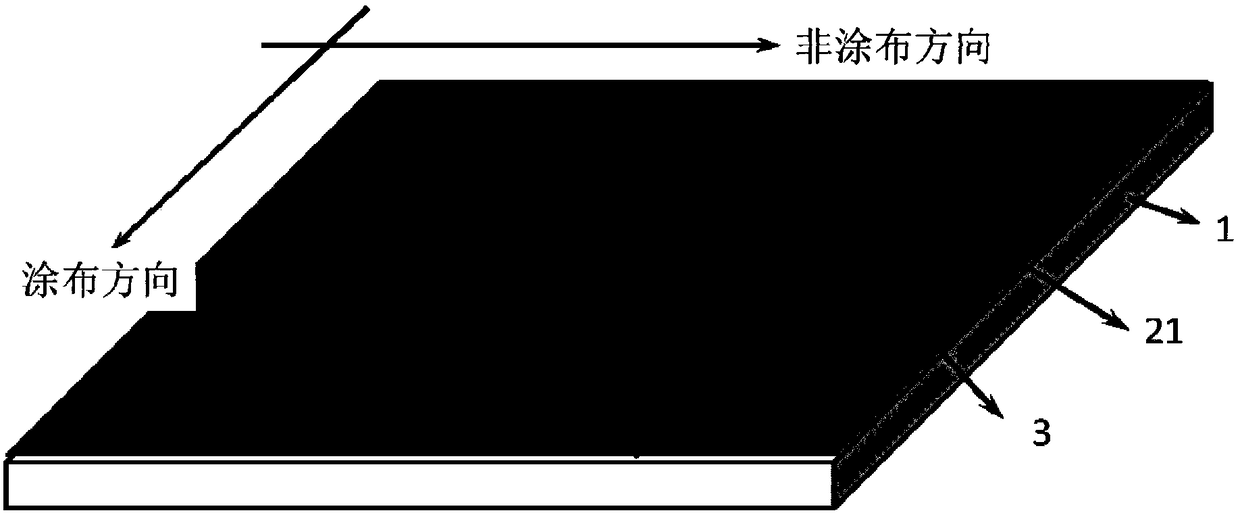

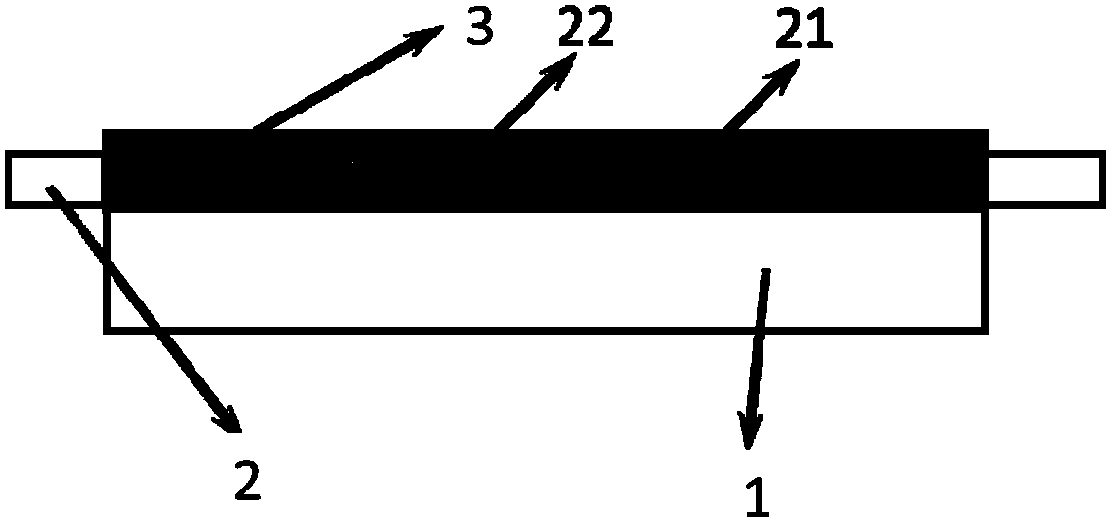

Image

Examples

Embodiment 1

[0086]Add 0.68% hexadecyltrimethylammonium bromide to the mixed solution of NJ-HZX-001 and HN-HZX-001 with a ratio of 1:1, and use a 15# wire bar to evenly coat it by scraping On the PET substrate, other processes are the same as in Comparative Example 1. The test results are shown in Table 1.

Embodiment 2

[0088] The mixture of NJ-HZX-001 and HN-HZX-001 treated with 0.67% sodium dodecylbenzene sulfonate at a ratio of 1:1 was evenly coated on PET by scraping with a 10# wire rod. On the base material, other processes are the same as in Comparative Example 1. The results are shown in Table 1.

Embodiment 3

[0090] Add 0.68% hexadecyltrimethylammonium bromide to the mixed solution of NJ-HZX-001 and HN-HZX-001 with a ratio of 1:1, and use a 30# wire rod to evenly coat it by scraping On the PET substrate, other processes are the same as in Comparative Example 1. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com