Battery safety evaluation device and battery safety evaluation method

A technology for safety evaluation and battery characteristics, applied in battery/fuel cell control devices, secondary battery charging/discharging, batteries, etc., can solve problems such as fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

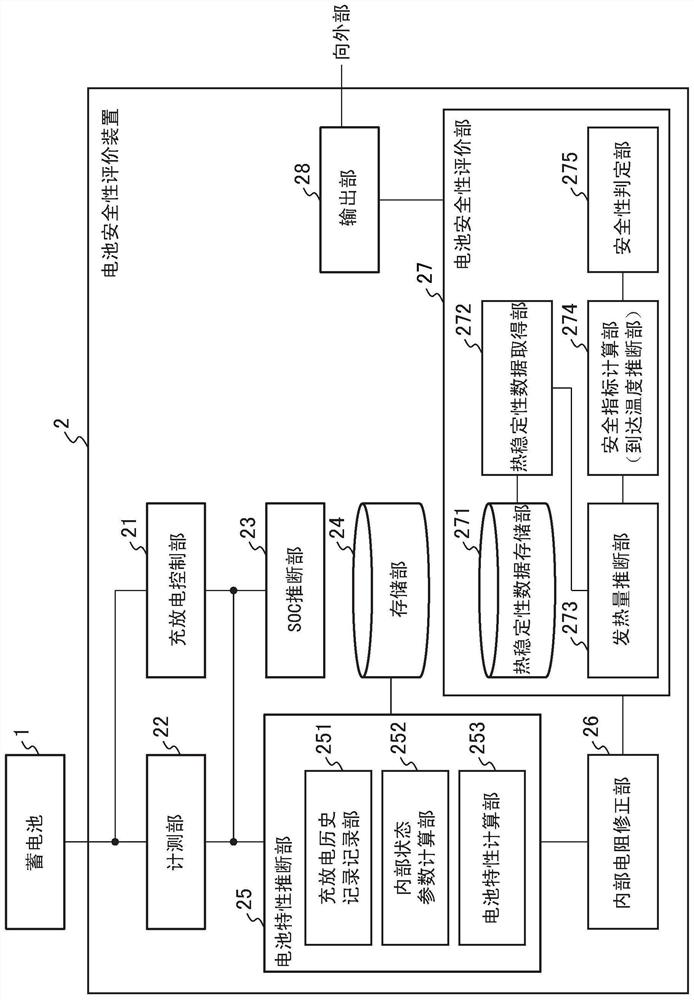

[0028] figure 1 It is a block diagram showing an example of a schematic configuration of a power storage system including the battery safety evaluation device according to the first embodiment. This power storage system includes a storage battery 1 (first battery) and a battery safety evaluation device 2 . The battery safety evaluation device 2 includes a charge and discharge control unit 21, a measurement unit 22, an SOC (State of Charge: State of Charge) estimation unit 23, a storage unit 24, a battery characteristic estimation unit 25, an internal resistance correction unit 26, a battery safety An evaluation unit 27 and an output unit 28 . The battery characteristic estimation unit 25 includes a charge and discharge history recording unit 251 , an internal state parameter calculation unit 252 , and a battery characteristic calculation unit 253 . The battery safety evaluation unit 27 includes a thermal stability data storage unit 271, a thermal stability data acquisition u...

no. 2 Embodiment approach

[0180] The battery safety evaluation device 2 of the second embodiment not only outputs the determined safety evaluation to an external device or the like, but also changes the control related to charging and discharging of the storage battery 1 based on the determined safety evaluation.

[0181] Figure 12 It is a block diagram showing an example of a schematic configuration of the power storage system according to the second embodiment. The second embodiment differs from the first embodiment in that the battery safety evaluation device 2 further includes a use condition calculation unit 29 . Description of the same points as those of the first embodiment will be omitted.

[0182] The charge and discharge control unit 21 performs charge and discharge control for not only evaluating the safety of the storage battery 1 but also for using the storage battery 1 . In addition, the charge and discharge control unit 21 changes the control of charge and discharge based on the safet...

no. 3 Embodiment approach

[0190] In the previous embodiment, the thermal stability data acquisition unit 272 acquires the thermal stability data corresponding to the storage battery 1 from the thermal stability data stored in the thermal stability data storage unit 271 . However, since the state of the storage battery 1 involves many aspects, if all the thermal stability data is stored in the thermal stability data storage unit 271, the capacity of the thermal stability data storage unit 271 will be huge. In addition, there may be a case where the thermal stability data corresponding to the storage battery 1 does not exist in the thermal stability data storage unit 271 . Therefore, in the third embodiment, acquisition and update of thermal stability data are performed from the outside. Accordingly, the amount of thermal stability data stored in the thermal stability data storage unit 271 can be reduced, and the size of the battery safety evaluation unit 27 and the cost reduction related to the producti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com