Tunnel operation safety test method under external water pressure

A test method and safety technology, applied in the hydraulic model and other directions, can solve the problems of overall safety test, inability to accurately reproduce the seepage characteristics of rock mass seepage field fissures, and the inability to accurately evaluate the actual impact of the project, to achieve reliable technical support, The effect of making up for the shortcomings of the standard calculation method and the numerical calculation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

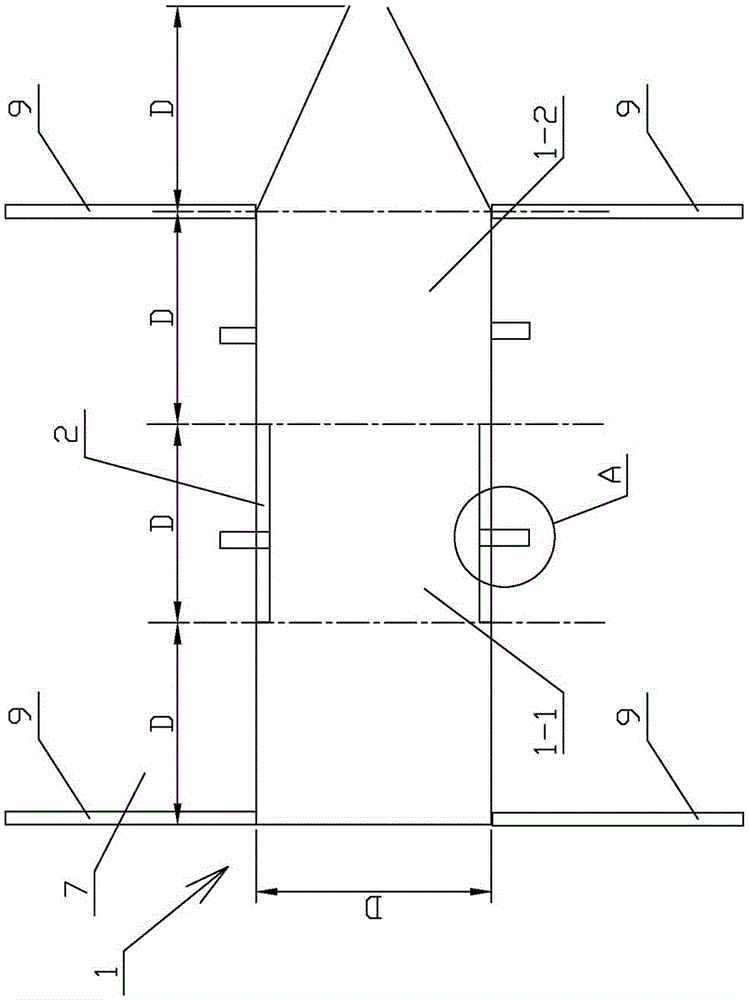

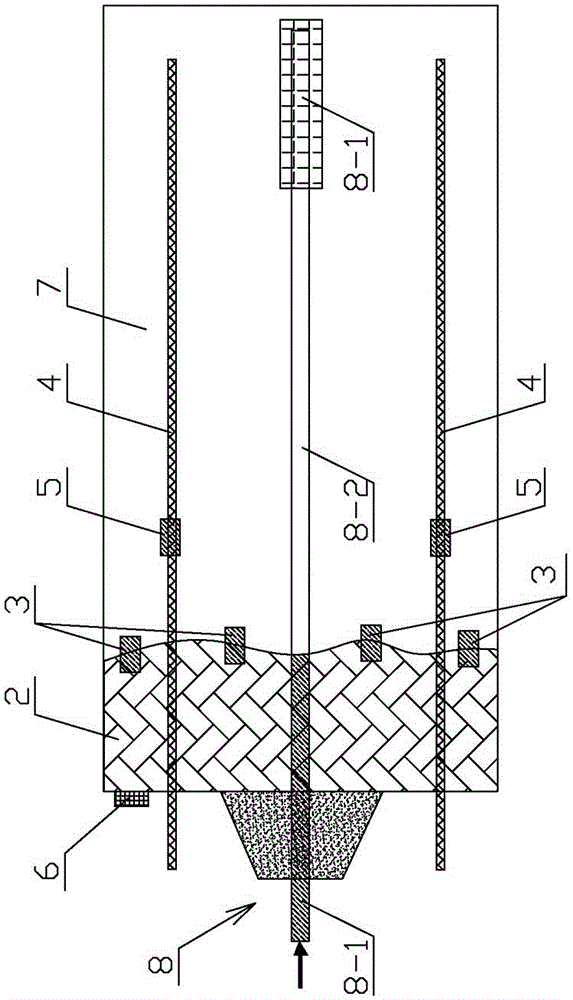

[0015] Such as figure 1 Shown, the test procedure of the present embodiment is as follows:

[0016] a. Excavate the test hole 1, and control the ratio of its size to the actual size of the tunnel at the site to be 1:1, so as to keep it as consistent as possible with the actual situation on site. The length of the test hole should preferably not be less than 4 times the hole diameter. The length of the test hole 1 in the example is 4 times of the hole diameter.

[0017] b. Divide the test hole 1 into four sections, of which the two sections at both ends are used to eliminate the tunnel face effect, and the length of the middle two sections is 1 times the hole diameter, which are respectively support area 1-1 and non-support area 1-2, for the convenience of comparison; the support area 1-1 is systematically supported according to the actual support measures on site, including shotcrete anchors and lining. In this example, since the total length of the test hole 1 is 4 times th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com