Detection method of air leakage rate of annular cooler based on blind source separation and unilateral detection method

A technology of blind source separation and detection method, which is applied in the direction of detecting the appearance of fluid at the leakage point, measuring device, processing discharged materials, etc., can solve the discharge temperature burns the production accident of the conveyor belt, and the lack of air leakage rate is effective. methods, blower energy waste and other issues, to achieve the effect of low implementation cost, good real-time performance, and reduced failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

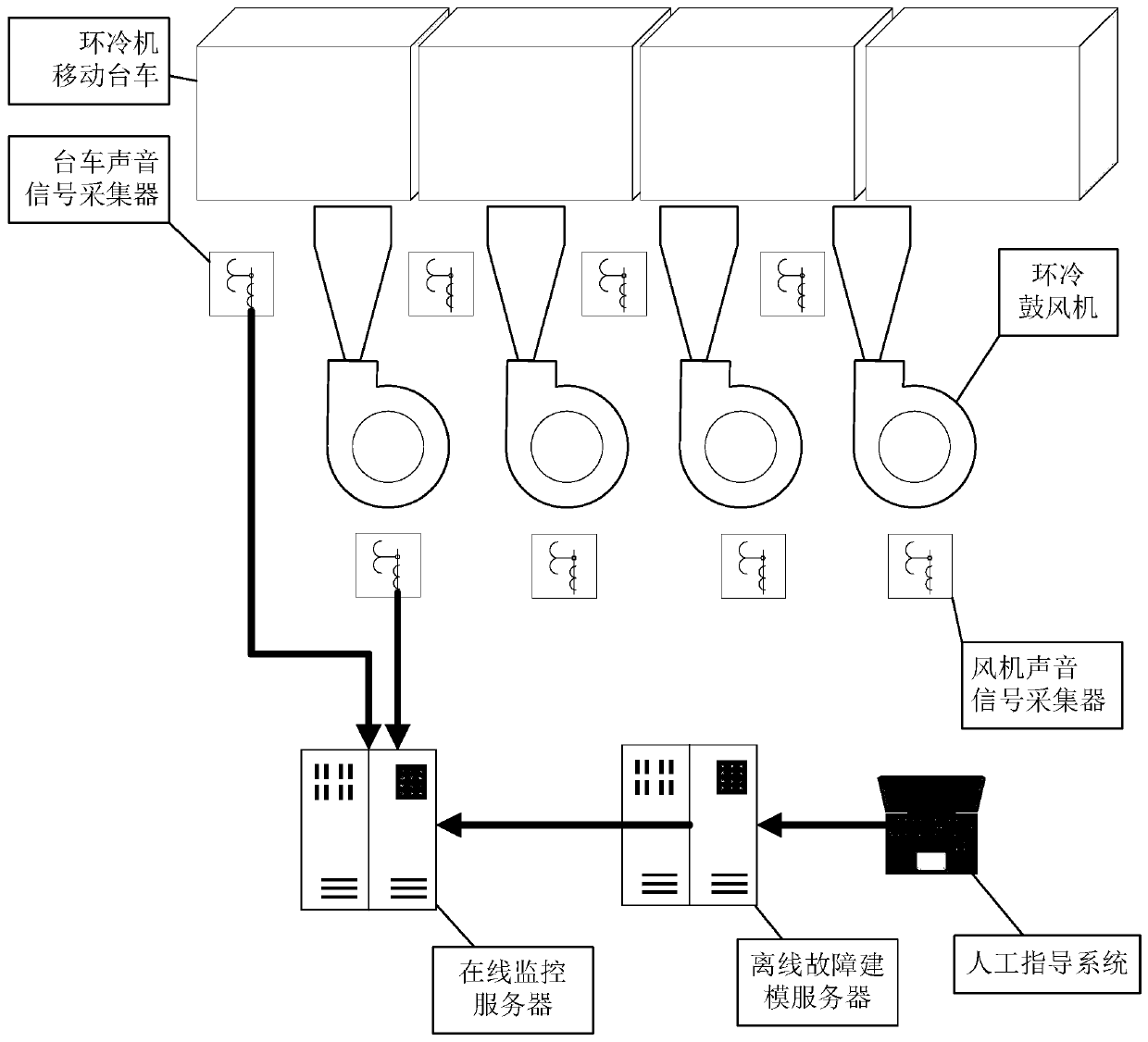

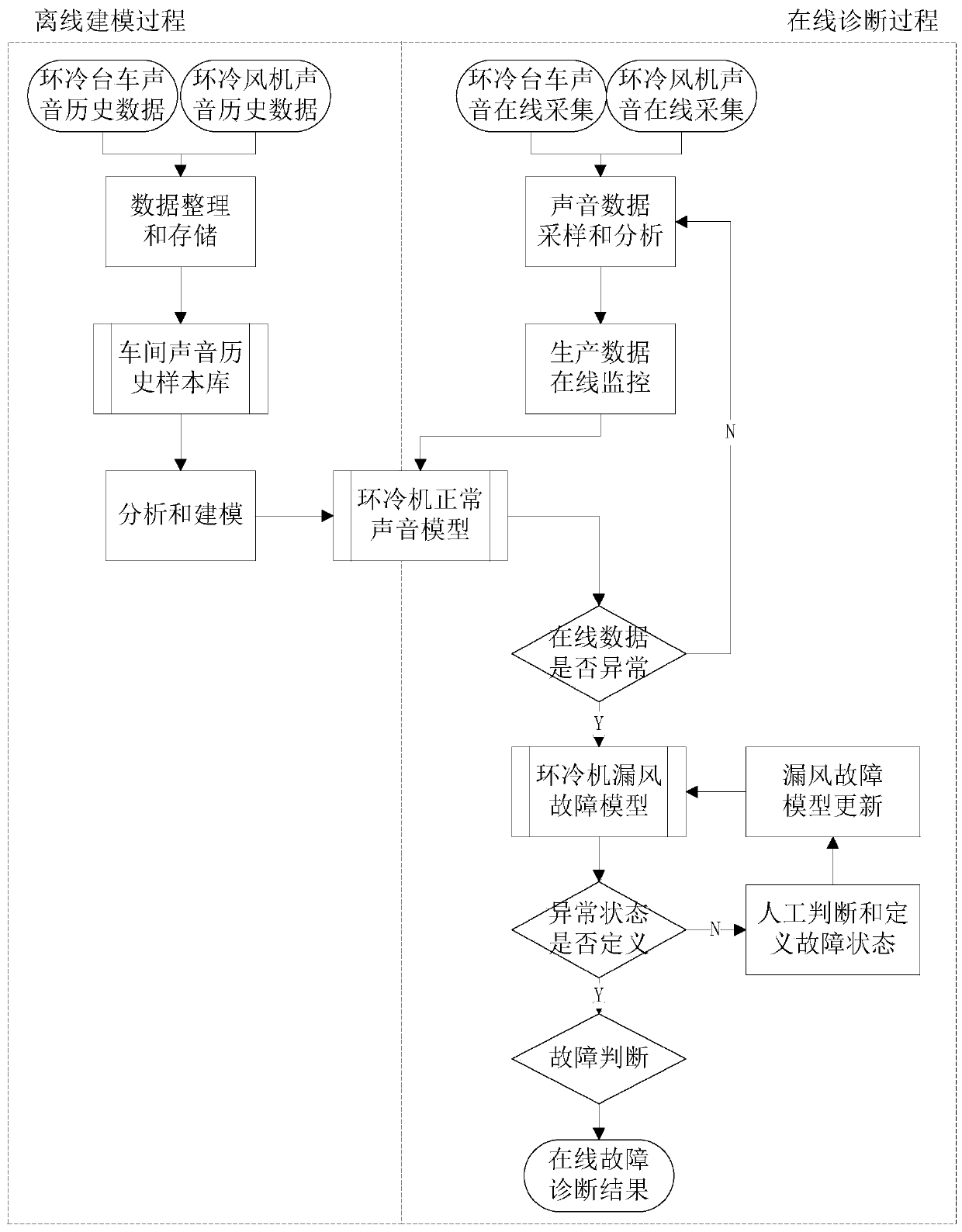

[0038] Combine figure 1 , figure 2 , image 3 with Figure 4 In this embodiment, a method for detecting the air leakage rate of a circulating cooler based on the blind source separation unilateral detection method is provided. A number of first sound signal collectors are installed at the ring cooler trolley, and a number of second sound signal collectors are installed at the ring cooler. For a sound signal collector, the method includes the following steps:

[0039] Including installing a number of first sound signal collectors at the ring cooler trolley, and installing a number of second sound signal collectors at the ring cooler, the method includes the following steps:

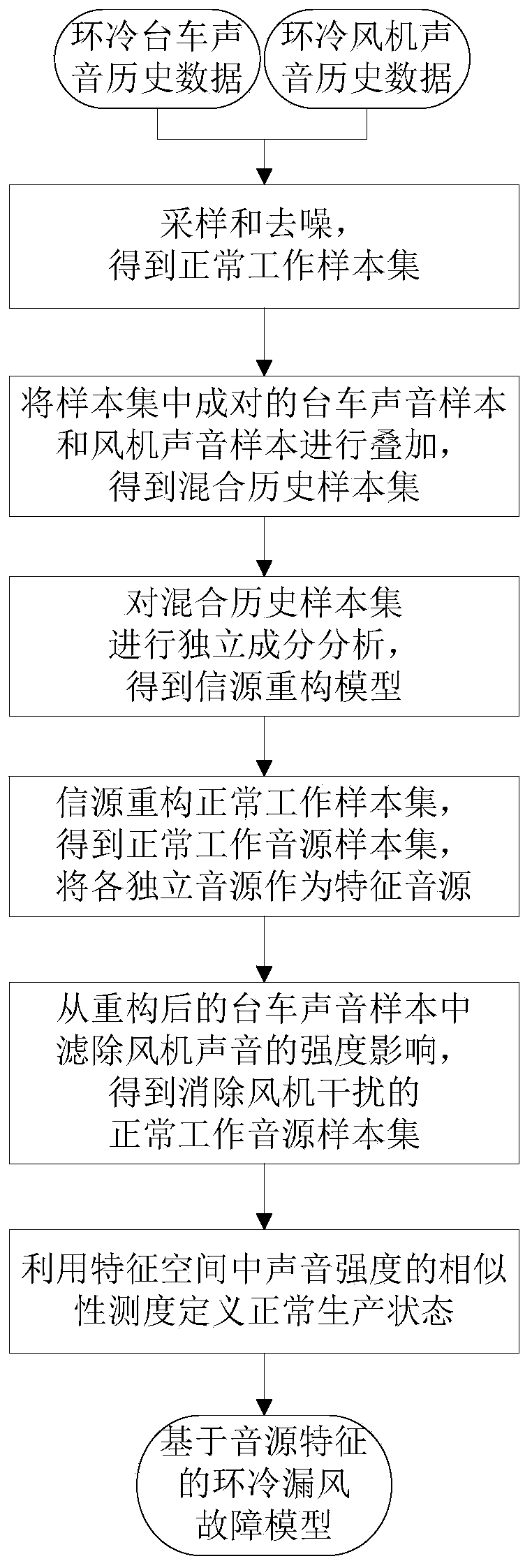

[0040] Step 1: Collect trolley sound data and fan sound data under normal working conditions to obtain trolley sound samples and fan sound samples. The trolley sound samples and fan sound samples correspond to each other according to time to form a normal data sample set X normal ;

[0041] Step 2: Perform supe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com