Horizontal type plate heat exchange mixed flow evaporator

An evaporator and plate exchange technology, which is applied in the field of horizontal plate exchange mixed flow evaporators, can solve the problems of low refrigeration efficiency and difficult oil return of refrigeration compressors, and achieve the effects of improving refrigeration efficiency, realizing large temperature difference and realizing process requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] exist Figure 7 Among them, the spray pipe (2), the equalizing plate (1), and the hypotenuse of the triangle (3) are all inside the horizontal plate exchange mixed flow evaporator. In the horizontal direction, the spray pipe (2) and the Freon liquid inlet pipe (10) are vertically connected in the lower right semicircular box; the equalizer plate (1) is a plate, which can cover the lower right semicircular box; multiple triangular angled plates The sheets are overlapped and welded together to form the ramp.

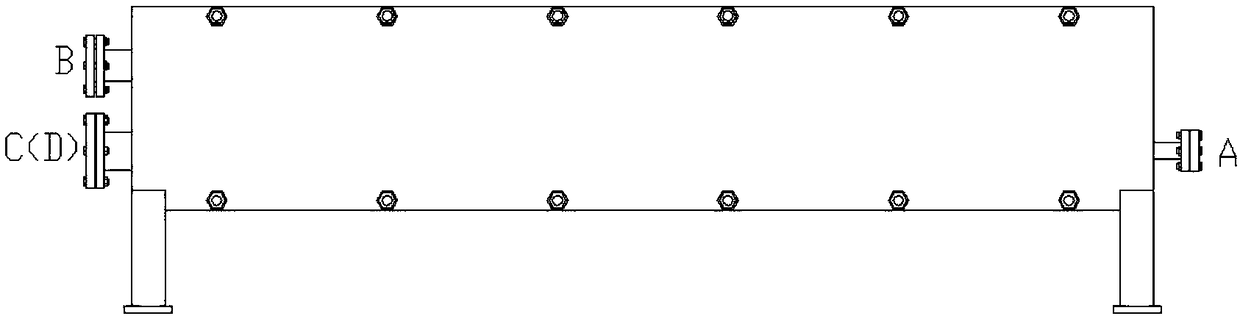

[0027] figure 1 , figure 2 , image 3 and Figure 4 Shown are views of each side of a horizontal plate exchange with one Freon flow channel and two water or material flow channels, indicating the overall appearance of the outside of the horizontal plate exchange mixed-flow evaporator.

[0028] Figure 5 and Figure 6 The direction of the Freon flow channel and the direction of the water or material flow channel in the horizontal plate exchange mixed flow eva...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com