Single-face conductive tape and production method

A technology of conductive cloth and conductive film, which is applied in the direction of adhesives, film/sheet adhesives, coatings, etc., can solve the problems of insufficient alcohol resistance and pollution of coatings, and achieve good alcohol resistance and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The new coating comprises in parts by mass: 35 parts of chlorinated polypropylene resin, 10 parts of isophorone, 0.1 part of polymethicone, and 10 parts of cyclohexanone.

Embodiment 2

[0036] The new coating comprises by mass: 55 parts of chlorinated polypropylene resin, 20 parts of isophorone, 1 part of polymethicone, and 20 parts of cyclohexanone.

Embodiment 3

[0038] The new coating on the surface of the conductive fiber 2 includes, in parts by mass: 40 parts of chlorinated polypropylene resin, 15 parts of isophorone, 0.5 part of polymethicone, and 15 parts of cyclohexanone.

[0039] Based on the above, the present application also provides a method for making the above-mentioned single-sided conductive cloth tape.

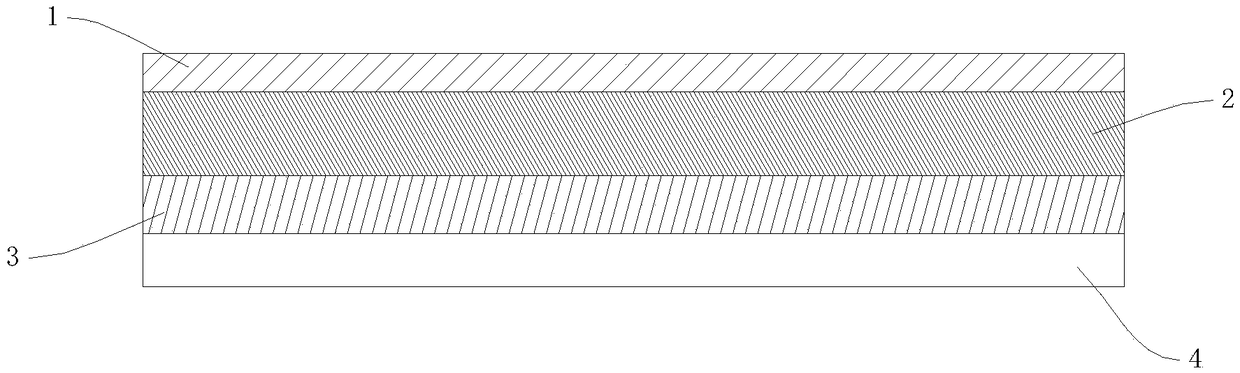

[0040] Such as figure 1 shown, including the following steps:

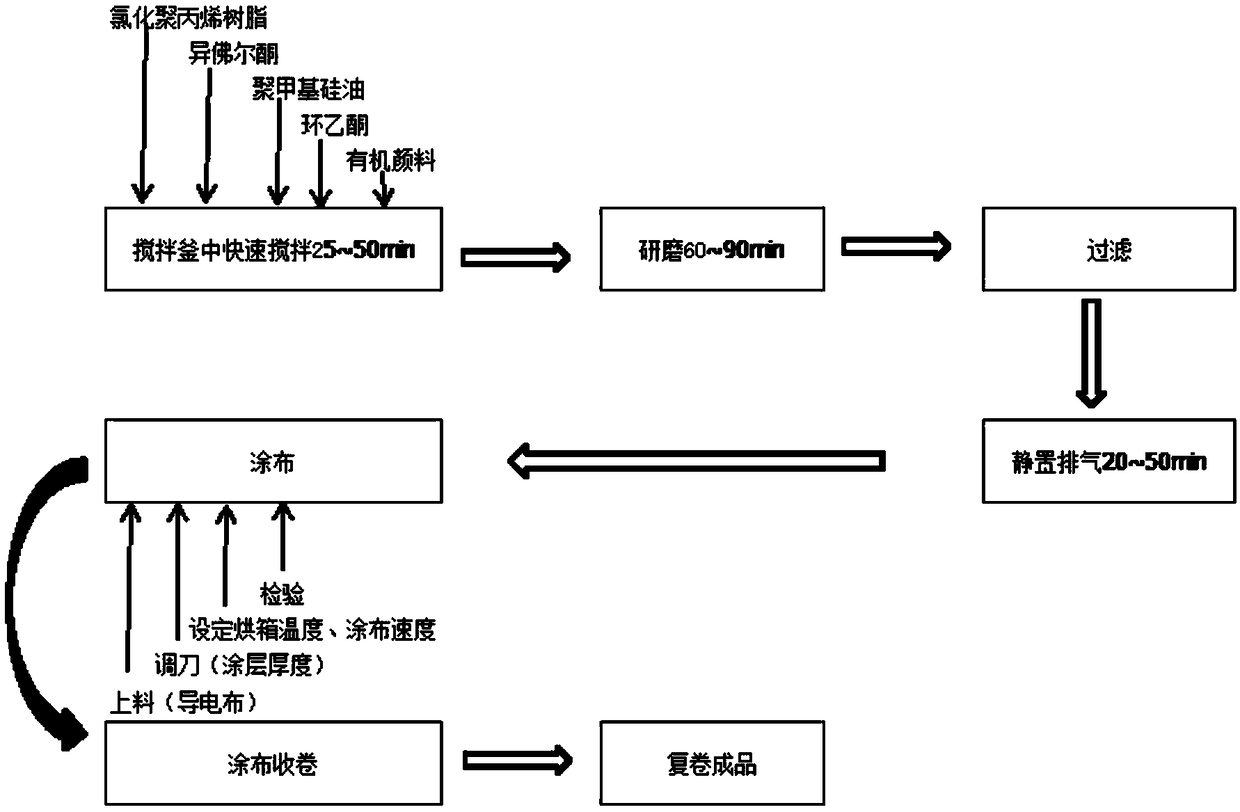

[0041] S0, making an insulating and alcohol-resistant coating 1, specifically including steps,

[0042] a. Add 35 to 55 parts of chlorinated polypropylene resin, 10 to 20 parts of isophorone, 0.1 to 1 part of polymethyl silicone oil and 10 to 20 parts of cyclohexanone to the stirred tank of the experimental machine in sequence For stirring and dispersing, 1200r / min to 1500r / min can be used to stir for 20min to 50min, and the specific stirring time can be 20min, 30min, 40min or 50min, so that the above components can be fully mixed together to form a unifo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com