Surface treating agent of pearlescent BOPP film and preparation method thereof

A technology of surface treatment agent and thin film, which is applied in the direction of coating, polyurea/polyurethane coating, etc., can solve the problems of dull and not bright picture, influence of inkjet effect, difficult to control holes, etc., and achieve good hydrolysis resistance and leveling property, Improve pearlescent effect and reduce surface tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

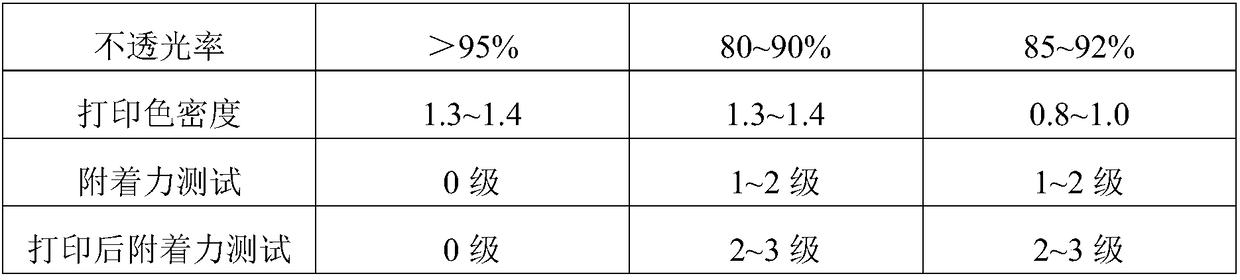

Examples

Embodiment 1

[0033] Surface treatment agent, its raw materials are: 2.5 parts of water-based polyacrylate emulsion, 1.5 parts of water-based anionic polyurethane dispersion, 1.5 parts of curing agent, 0.2 part of ammonia water, 0.02 part of wetting agent, and 6 parts of water.

[0034] Follow the steps below to prepare the surface treatment:

[0035] 1. Add water-based polyacrylate emulsion and deionized water (temperature: 10-20°C) into the mixing tank, start stirring to 200r / min, add water-based polyacrylate emulsion and wetting agent while stirring, and stir evenly;

[0036] 2. Add ammonia water to adjust the pH of the solution to 7-8, and stir evenly;

[0037] 3. Add water-based anionic polyurethane dispersion and stir evenly;

[0038] 4. Add curing agent and stir evenly;

[0039] 5. Filter with a 200-mesh filter for use. After preparation, it should be stored in a sealed environment at 10-20°C and used up within 4-6 hours.

Embodiment 2

[0041] Surface treatment agent, its raw materials are: 4 parts of water-based polyacrylate emulsion, 0.5 part of water-based anionic polyurethane dispersion, 2.5 parts of curing agent, 0.3 part of ammonia water, 0.05 part of wetting agent, and 10 parts of water.

[0042] Follow the steps below to prepare the surface treatment:

[0043] 1. Add water-based polyacrylate emulsion and deionized water (temperature: 10-20°C) into the mixing tank, start stirring to 300r / min, add water-based polyacrylate emulsion and wetting agent while stirring, and stir evenly;

[0044] 2. Add ammonia water to adjust the pH of the solution to 7-8, and stir evenly;

[0045] 3. Add water-based anionic polyurethane dispersion and stir evenly;

[0046] 4. Add curing agent and stir evenly;

[0047] 5. Filter with a 200-mesh filter for use. After preparation, it should be stored in a sealed environment at 10-20°C and used up within 4-6 hours.

Embodiment 3

[0049] Surface treatment agent, its raw materials are: 3 parts of water-based polyacrylate emulsion, 1 part of water-based anionic polyurethane dispersion, 1.2 parts of curing agent, 0.1 part of ammonia water, 0.05 part of wetting agent, and 8 parts of water.

[0050] Follow the steps below to prepare the surface treatment:

[0051] 1. Add water-based polyacrylate emulsion and deionized water (temperature: 10-20°C) into the mixing tank, start stirring to 300r / min, add water-based polyacrylate emulsion and wetting agent while stirring, and stir evenly;

[0052] 2. Add ammonia water to adjust the pH of the solution to 7-8, and stir evenly;

[0053] 3. Add water-based anionic polyurethane dispersion and stir evenly;

[0054] 4. Add curing agent and stir evenly;

[0055] 5. Filter with a 200-mesh filter for use. After preparation, it should be stored in a sealed environment at 10-20°C and used up within 4-6 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com