Preparation method of cationic core-shell fluorinated acrylate-alkyd resin surface sizing agent

A technology of surface sizing agent and alkyd resin, which is applied in the direction of water-repellent addition, reinforcing agent addition, coating, etc., which can solve the unsatisfactory oil repellency, heat resistance, weather resistance, and water and oil repellency , poor water resistance and weather resistance of the coating film, etc., to increase the physical strength, improve the waterproof and oil-proof performance, and improve the effect of water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

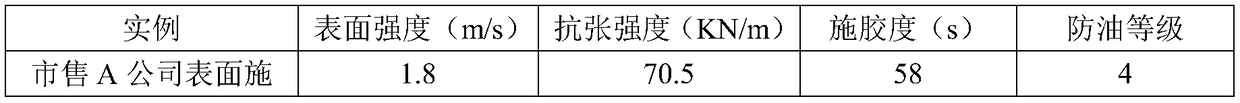

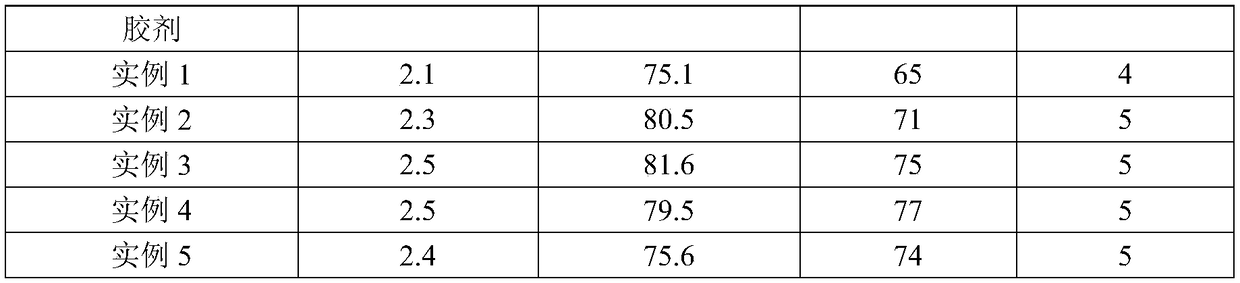

Examples

preparation example Construction

[0022] A preparation method of a cationic core-shell fluorine-containing acrylate-alkyd resin surface sizing agent of the present invention comprises the steps of: mixing 10-45 parts of alkyd resin, 0.5-2.0 parts of initiator azobisisobutyronitrile and auxiliary Add 5-20 parts of solvent to the reaction container together, raise the temperature to 70-130°C, stir until the alkyd resin is completely dissolved and record it as component A; mix monomers (soft monomer 0-8 parts, hard monomer 12-20 parts, 1-3 parts of stearyl acrylate, 5-10 parts of vinyl fluorine-containing monomer) and 0.5-1.0 parts of the remaining initiator are mixed and ultrasonicated, so that the initiator is completely dissolved in the monomer, and the mixed system Record it as component B, add component B dropwise to component A within 2-4 hours, continue to keep warm for 2-3 hours to obtain component C; then mix the monomer (dimethylaminoethyl methacrylate 1 -5 parts, 0-8 parts of soft monomer, 12-20 parts ...

Embodiment 1

[0025] A preparation method of a cationic core-shell fluorine-containing acrylate-alkyd resin surface sizing agent, comprising the following steps:

[0026] Add 25 parts of alkyd resin, 0.7 parts of initiator azobisisobutyronitrile and 12 parts of cosolvent into the reaction vessel together, raise the temperature to 90°C, stir until the alkyd resin is completely dissolved and record it as component A; mix the Monomer (2 parts of soft monomer, 15 parts of hard monomer, 1 part of stearyl acrylate, 6 parts of hexafluorobutyl acrylate) and 0.5 parts of the remaining initiator are mixed ultrasonically, so that the initiator is completely dissolved in the monomer, The mixed system is recorded as component B, and component B is added dropwise to component A within 2 hours, and the reaction is continued for 2 hours to obtain component C; then the mixed monomer (dimethylaminoethyl methacrylate 3 1 part, 1 part of soft monomer, 15 parts of hard monomer, 2 parts of stearyl acrylate, 8 pa...

Embodiment 2

[0028] A preparation method of a cationic core-shell fluorine-containing acrylate-alkyd resin surface sizing agent, comprising the following steps:

[0029] Add 35 parts of alkyd resin, 1.5 parts of initiator azobisisobutyronitrile and 17 parts of cosolvent into the reaction vessel together, raise the temperature to 100°C, stir until the alkyd resin is completely dissolved and record it as component A; mix Monomer (7 parts of soft monomer, 16 parts of hard monomer, 2.5 parts of stearyl acrylate, 5-109 parts of vinyl fluorine-containing monomer) and 1.3 parts of remaining initiator were mixed ultrasonically, so that the initiator was completely dissolved in the single In the body, record the mixed system as component B, add component B dropwise to component A within 3 hours, and continue the heat preservation reaction for 3 hours to obtain component C; then mix the monomer (dimethylaminomethacrylate 5 parts of ethyl ester, 4 parts of soft monomer, 18 parts of hard monomer, 2.4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com