A kind of high-strength anti-seepage concrete and its production method

A technology of impervious concrete and high strength, which is applied in the field of concrete and can solve the problems of poor impermeability of high-strength concrete

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Embodiment 1: A high-strength impermeable concrete, including the components shown in Table 1 in parts by weight.

[0048] Among them, the cement is P.O52.5 cement; the fine aggregate is medium sand in Zone II; the coarse aggregate is continuously graded gravel with a minimum particle size of 5mm and a maximum particle size of 25mm; the water reducer is FDN high-efficiency Retarding water reducer; air-entraining agent selection of rosin resin air-entraining agent.

[0049] Polyvinyl alcohol fibers with a diameter of 31 μm and a length of 11 mm and steel fibers with a diameter of 0.4 mm and a length of 12 mm arranged in a wave shape were selected. The particle size of magnesium oxide particles is selected from 31μm-45μm

[0050] The above-mentioned high-strength impermeable concrete is prepared through the following steps:

[0051] S1, weighing the fine powder composition, cement, magnesium oxide particles and fine aggregate in corresponding parts by weight, and mixing...

Embodiment 2-8

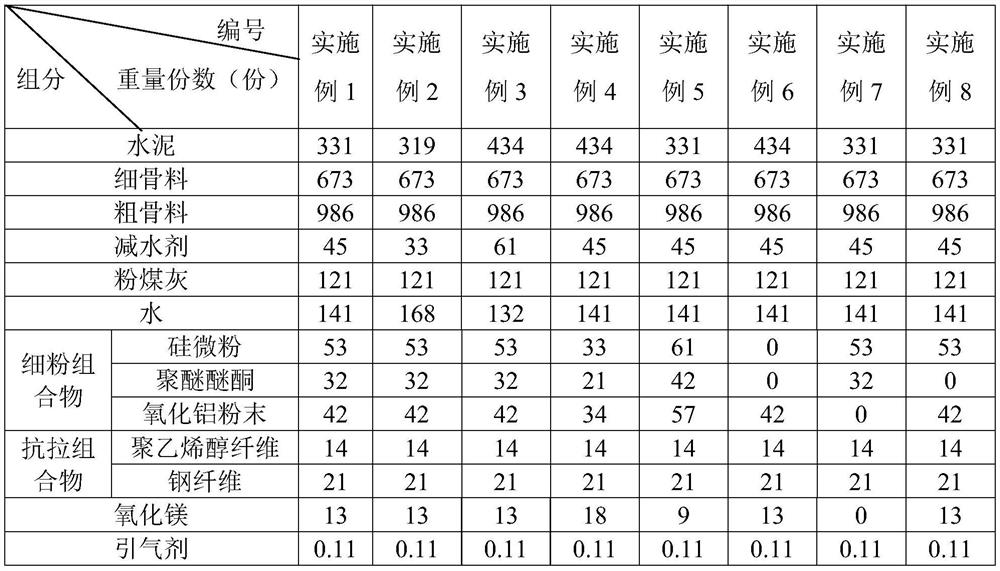

[0054] Example 2-8: A high-strength impermeable concrete, the only difference from Example 1 is that the parts by weight of some components are different; the components and parts by weight are shown in Table 1.

[0055] Components and their corresponding parts by weight in table 1. embodiment 1-8

[0056]

Embodiment 9

[0057] Embodiment 9: A high-strength impermeable concrete. The only difference from Embodiment 1 is that polyvinyl alcohol fibers and steel fibers are selected in parts by weight of 12 and 13 parts respectively, and the remaining parameters are consistent with Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com