Limiting device for steel pipe surface detection and limiting method thereof

A surface detection and limit device technology, which is applied in the direction of length measuring device, rolling mill control device, metal rolling, etc., can solve the problems of steel pipe surface image defocus, large jumping range, fast steel pipe movement speed, etc., to ensure online detection Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

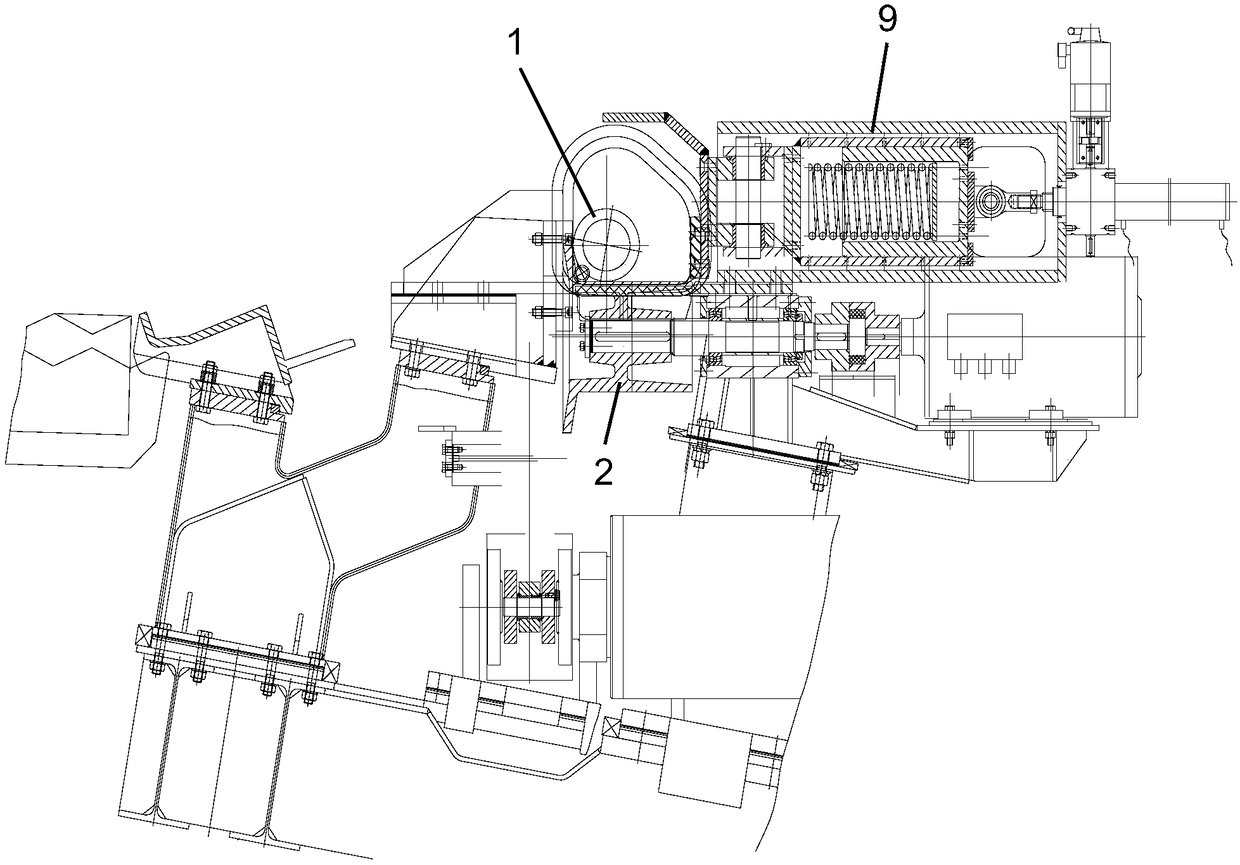

[0029] Please combine Figure 2 to Figure 4 As shown, a limit device for steel pipe surface detection provided by the present invention is located in front or / and behind the seamless steel pipe surface detection system 6, and is connected to the on-site production information system. In this embodiment, respectively Arrange a limit device 9 in front and rear of the seamless steel pipe surface detection system 6, and arrange a hot metal detector 7 below the limit device 9 to judge whether the steel pipe 8 reaches the limit device 9 position, this limiting device 9 comprises side baffle 91, rotating shaft center 92, adjustment mechanism 93 and spring 94, and side baffle 91 is located at the top of steel pipe 8, and the operation of steel pipe 8 is restrained, and rotating shaft center 92 Be connected to the front end of the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com