Gas particulate filter tank structure internally provided with one-way valve

The technology of a canister and a one-way valve is applied in the direction of breathing filter, respiratory protection device, life-saving equipment, etc., which can solve the problems of poor filtering effect, easy damage of the one-way valve, and damage to the sealing performance of the hood, etc. To achieve good protection effect, improve the use effect, improve the effect of filtering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

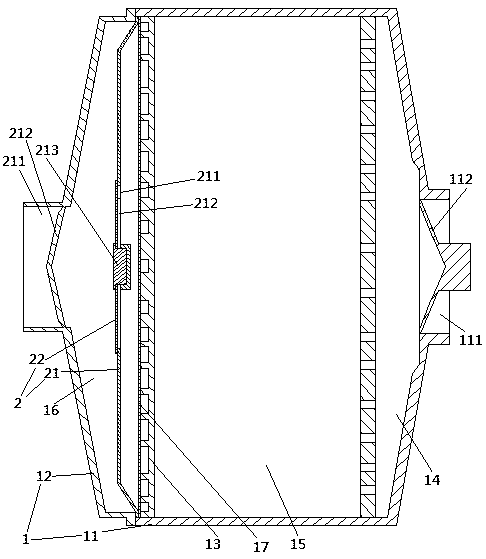

[0020] Embodiment one, see figure 1 , a canister structure with a built-in check valve, including a canister 1. The canister is made of plastic. The canister includes an air inlet section 11 and an air outlet section 12 . The air inlet section 11 and the air outlet section 12 are hermetically connected together. Two grid plates 13 are arranged in the canister. The two grid plates divide the canister into an air inlet chamber 14 , a poison filter material storage chamber 15 and an air outlet chamber 16 . Both the air intake chamber 14 and the poison filter material storage chamber 15 are located in the air intake section. The intake section 11 is provided with an intake hole 111 communicating with the intake chamber. The air inlet is provided with an air inlet cover 112 . The air intake cover and the canister are integrally formed together. An impact post 113 is integrally formed on the outer surface of the air inlet cover. The impact post protrudes from the air intake ...

Embodiment 2

[0022] Embodiment two, the difference with embodiment one is:

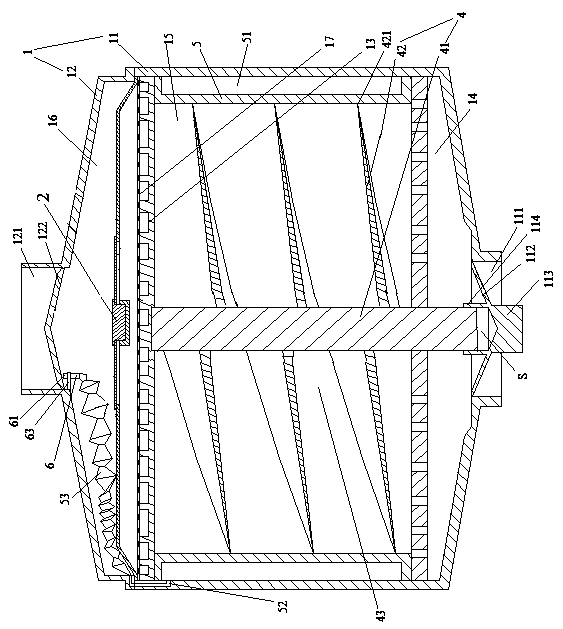

[0023] see figure 2 with image 3 , The inner surface of the air inlet cover is provided with a connecting sleeve 114 .

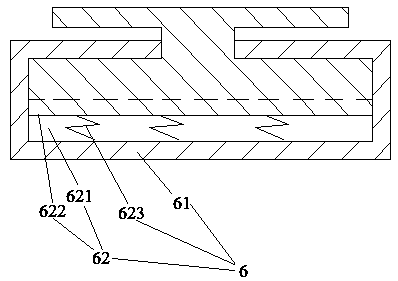

[0024]A time-space conversion delay mechanism 4 is provided in the poison filter material storage chamber 15 . The time-space conversion delay mechanism includes a central shaft 41 and a spacer 42 with a helical structure arranged on the central shaft. The central axis extends along the distribution direction of the air inlet holes and the air outlet holes. A flexible layer 5 is arranged on the inner peripheral surface of the poison filter material storage cavity. A sealed air cavity 51 is formed between the flexible layer and the peripheral surface of the canister. The airtight cavity is filled with oxygen to generate a positive pressure so that the flexible layer is sealed against the edge of the spacer away from the central axis. A spiral air channel 43 is formed between the spacer, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com