Heavy metal ion beam cutting machining instrument

A cutting and ion beam technology, applied in the sampling device and other directions, can solve problems such as operation errors, sample damage, and reduce the operational range of the sample, and achieve the effects of reducing damage, high space utilization, and increasing the operational area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

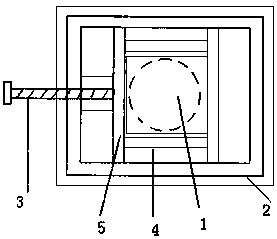

[0009] Such as figure 1 As shown, the technical solution of the present invention is: a heavy metal ion beam cutting processing instrument, including a base, a backing plate, a shaft, and a metal gasket, the base is a cylinder, and the base supports the backing plate; the surface of the backing plate is There is a rectangular groove, and the end face of the rectangular groove is provided with an adjustable and movable shaft, and the rectangular groove is connected with a metal gasket; the position of the metal gasket in the rectangular groove; the shaft can be realized by bolts; the The above-mentioned base directly fixes the fixing device on the porous standard sample stage, and in order to make the sample conduct electricity, the entire carrier uses a metal material.

[0010] The invention has the advantages of simple structure, convenient maintenance, low cost, high space utilization rate, convenient and fast transportation, reduces damage to samples during sampling, and in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com