High-speed revolution split-type shaft system of large-size three-dimensional space integral measurement position indicator

A three-dimensional space, overall measurement technology, applied in the field of measurement, can solve the problems of difficult processing, difficult assembly, long processing cycle, etc., to achieve the effect of reducing processing difficulty and cost, shortening processing cycle, and controllable assembly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below by means of the accompanying drawings and examples.

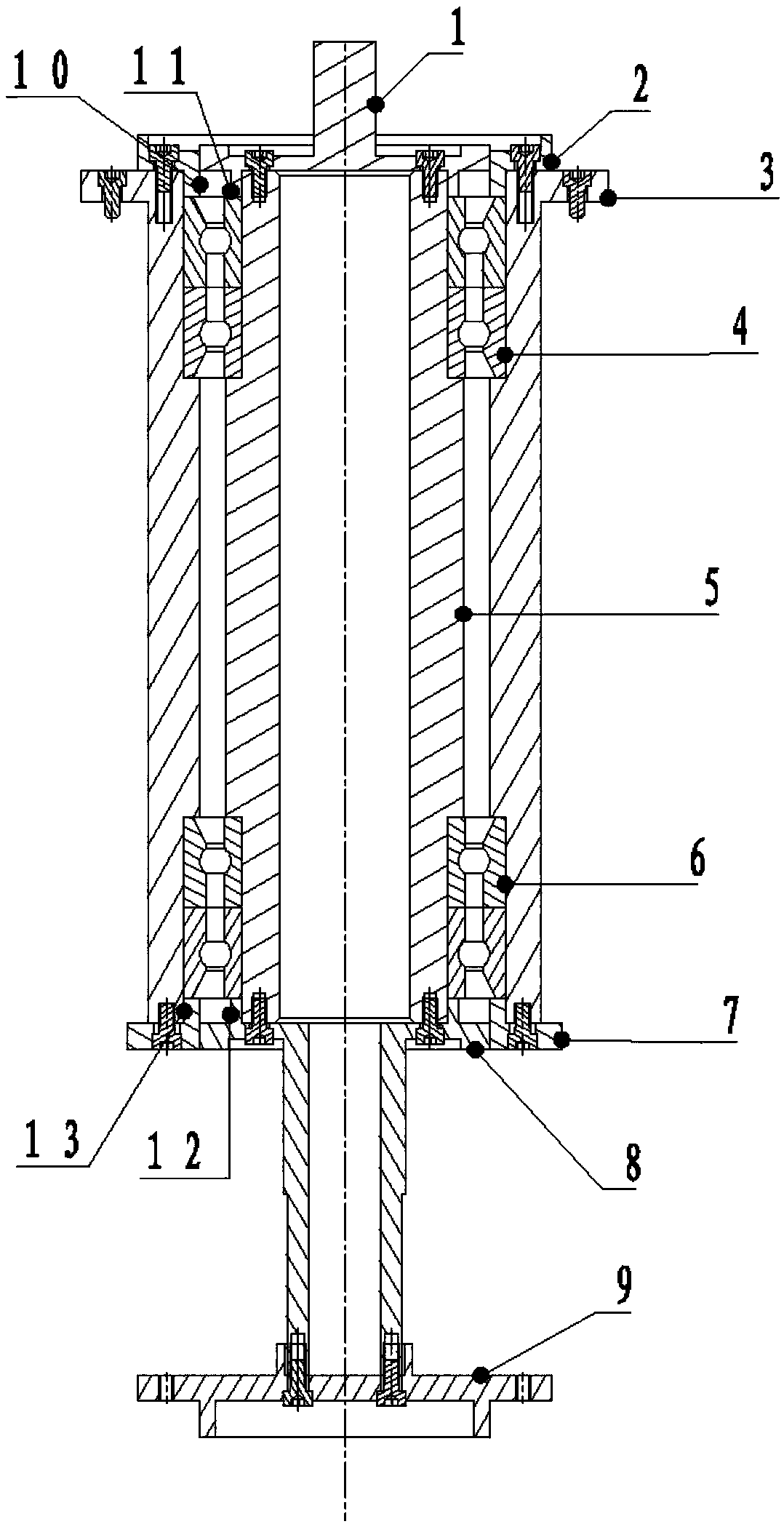

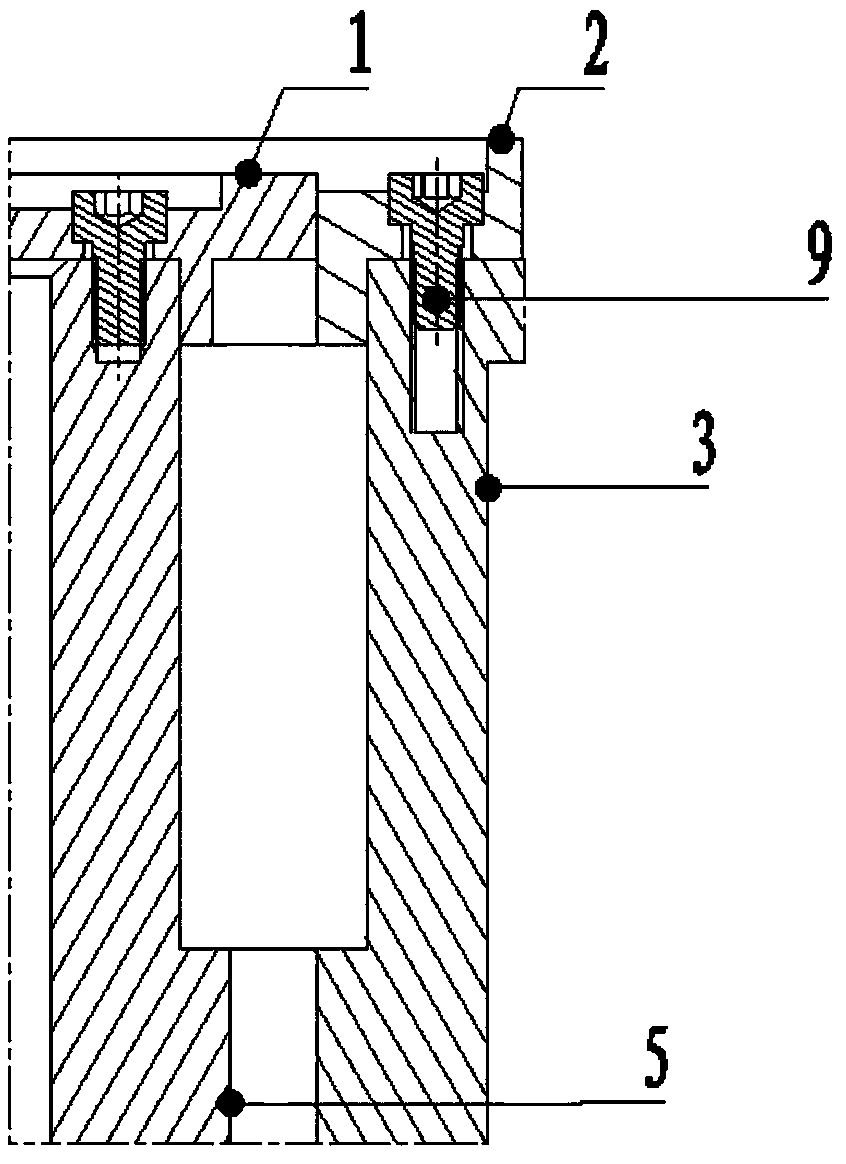

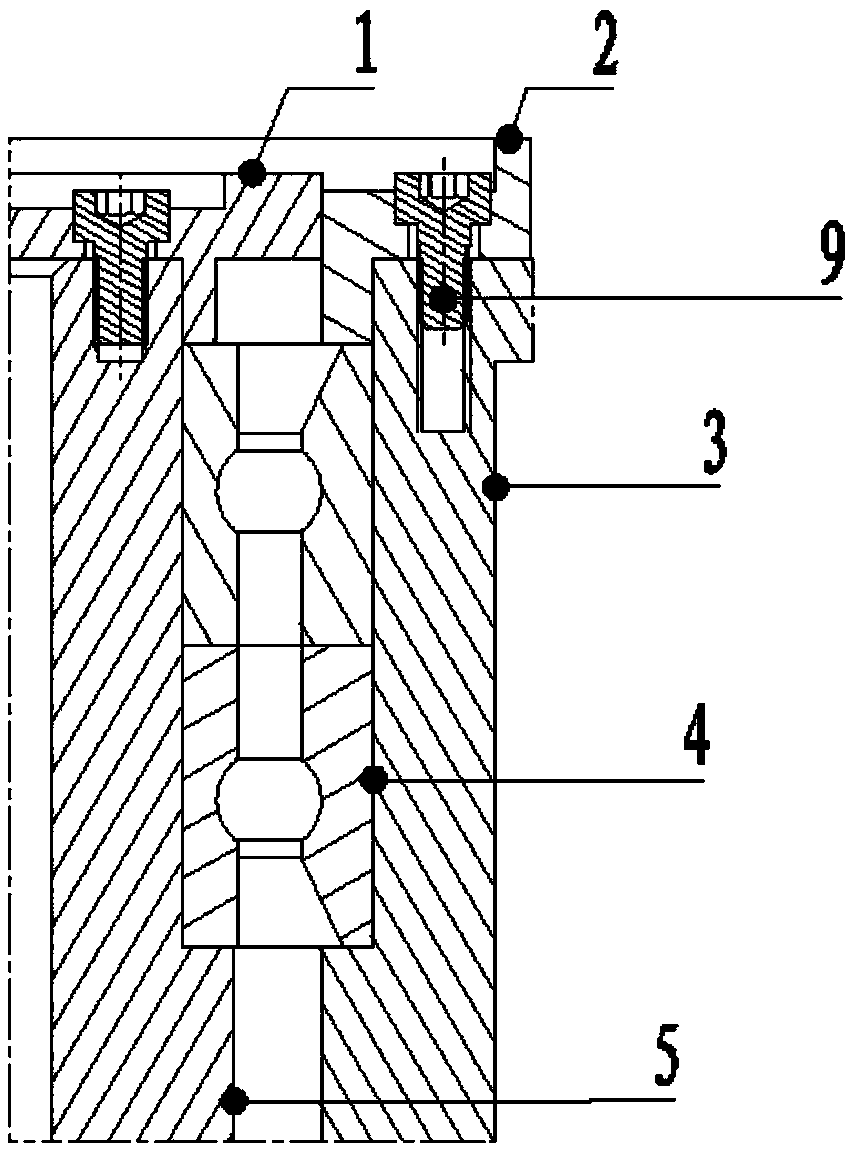

[0029] see figure 1As shown, the high-speed rotary split shaft system of the present invention includes: upper bearing inner gland 1, upper bearing outer gland 2, bushing 3, angular contact ball bearing 4, main shaft 5, lower bearing outer gland 6, lower bearing Inner gland 7, connecting cover 8, connecting adjustment screw 9, upper bearing outer gland annular positioning boss 10, upper bearing inner gland annular positioning boss 11, lower bearing inner gland annular positioning boss 12, lower bearing outer Gland annular positioning boss 13. The main body shaft 5 is divided into upper, middle and lower sections by the shoulder part. The shaft diameters of the upper and lower sections are the same, and the shaft diameter of the middle section is larger than that of the upper and lower sections. The upper angular contact ball bearing 4 is inserted into t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com