Mandrel heat preservation device and mandrel temperature adjustment system

A technology of heat preservation device and temperature adjustment system, which is applied in the field of seamless steel pipes, can solve problems such as uneven heating temperature and influence on the environment, achieve uniform heating, ensure uniform heating effect, and protect the environment by heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

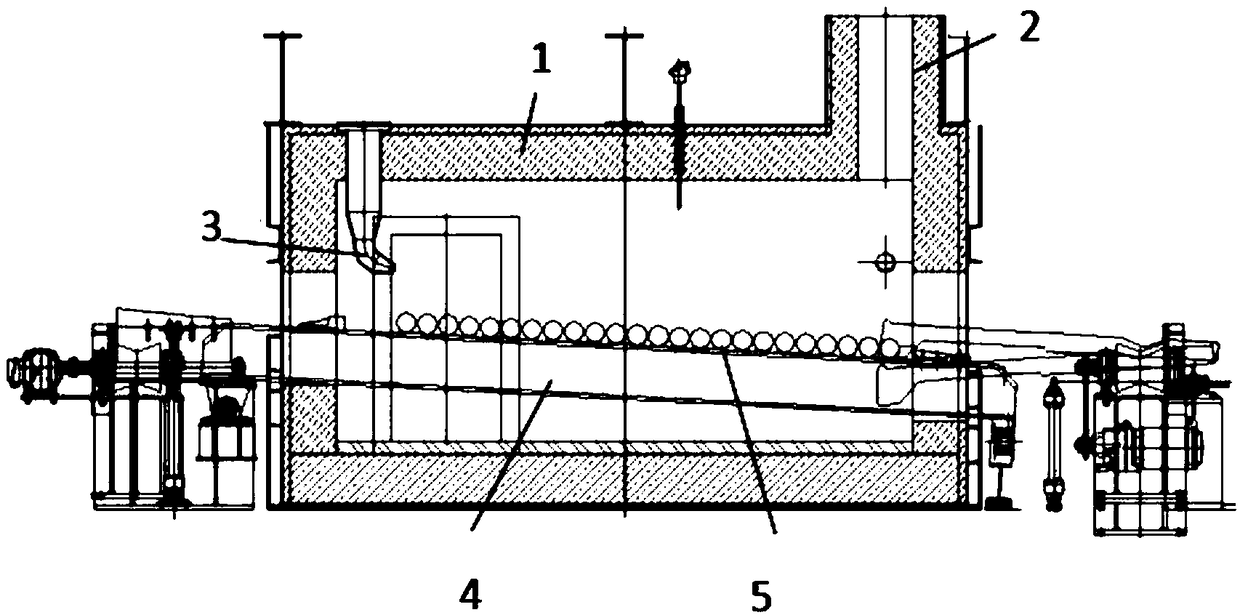

[0039] figure 1 A schematic structural view of the mandrel insulation device provided in Embodiment 1 of the present invention, such as figure 1 As shown, the mandrel insulation device provided by the embodiment of the first aspect of the present invention includes a swing beam 4 and a closed furnace body 1, the swing beam 4 is penetrated in the furnace body 1, and on the swing beam 4 A mandrel 5 is provided, and a burner 3 is provided on the furnace body 1 corresponding to the mandrel 5, and the burner 3 is provided with flue gas, and the furnace body 1 is provided with a flue gas for exhausting the flue gas. Road 2.

[0040] In the mandrel insulation device provided by the present invention, the furnace body 1 is provided with a burner 3 corresponding to the mandrel 5, the burner 3 is provided with flue gas, and the furnace body 1 is provided with a The flue 2 of the gas; through the flue gas heating, the local high temperature of the flame is avoided, and the mandrel 5 is...

Embodiment 2

[0056] In order to protect the environment, in any of the above technical solutions, further, the flue 2 is connected to an induced draft fan, and the flue gas is exhausted to the outside through the induced draft fan. Prevent the environmental pollution of the processing site from being large and causing great harm to personnel. The rest are the same as the first embodiment, and will not be repeated here.

[0057] In the mandrel heat preservation device provided by the present invention, the mandrel 5 is uniformly heated in a relatively closed space of the furnace body 1, and the heat uniformity effect is optimal. At the same time, with the control of the opening degree of the electromagnetic valve in the burner 3 and the temperature of the flue gas, the temperature can be adjusted according to the actual situation of the mandrel 5 to the greatest extent, so as to ensure the uniform heating effect of the mandrel 5 in the furnace body 1 . The movement of the mandrel 5 on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com