Gas cooker heat-recycle heating cup device

A technology for heating cups and gas stoves, which is applied in the direction of gaseous heating fuel, heating methods, lighting and heating equipment, etc. It can solve the problems of the upper panel of the gas stove box, such as bursting, high temperature resistance, energy waste, etc., to reduce the risk of bursting , prolong the service life and reduce the temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with specific accompanying drawing, the present invention will be further described:

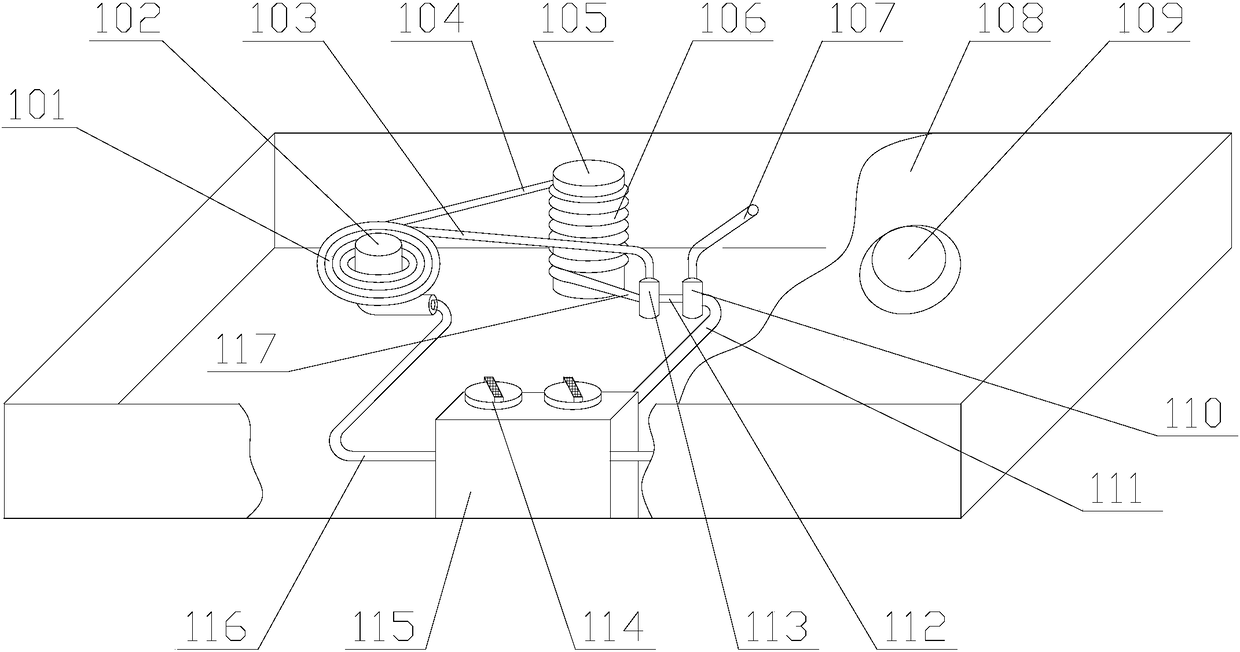

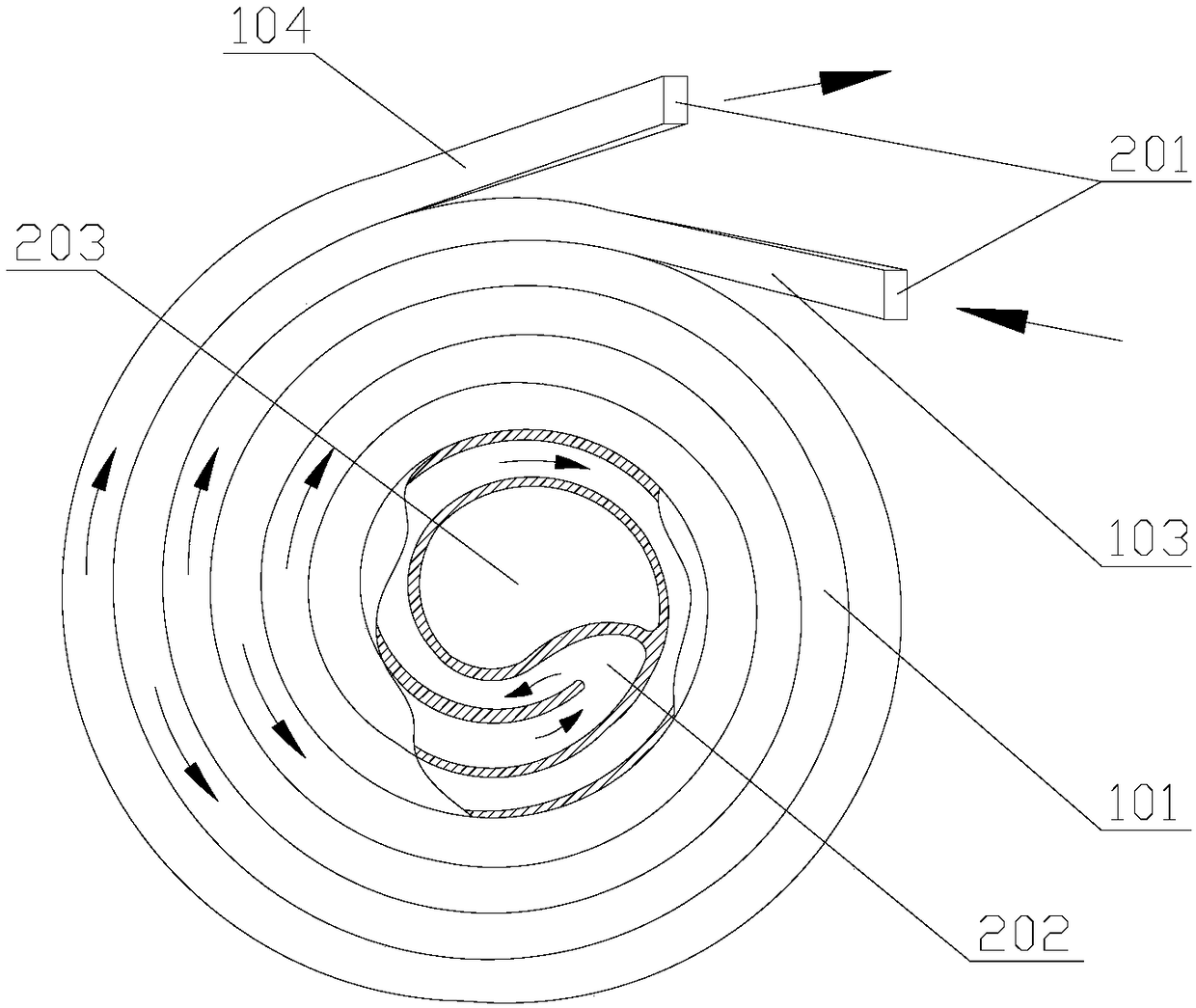

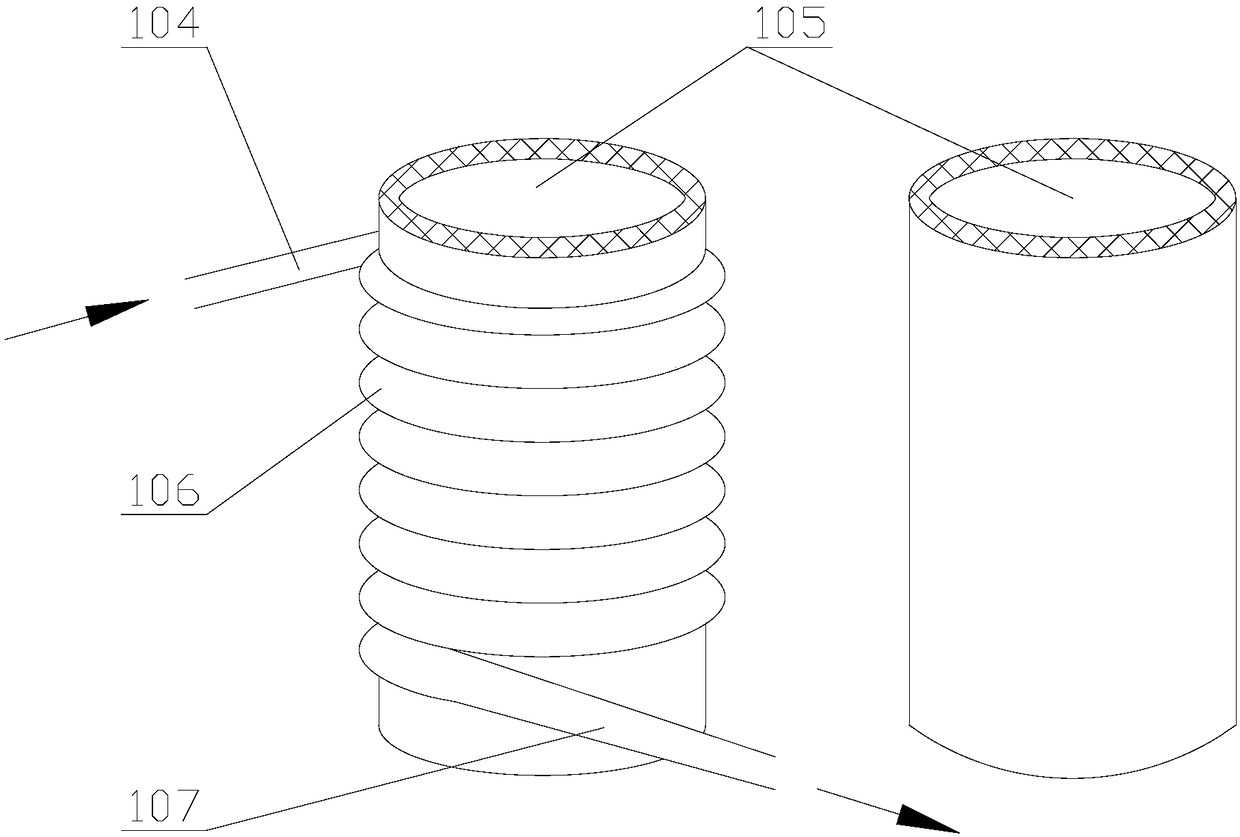

[0026] Such as figure 1 As shown, a heating cup device for reusing heat energy of a gas stove in the embodiment includes a heat absorbing plate 101, such as figure 2 As shown, the pipeline in the heat absorbing plate 101 is designed as an involute shape, and a burner hole 203 is designed in the middle, and the size of the burner hole 203 is adapted to the diameter of the gas stove burner 102, so that the burner 102 can pass through Stove head hole 203, so that gas burns and heats pan. In the middle of the heat absorbing plate 101, there is a heat absorbing plate connecting port 202, which is used to connect the heat absorbing plate water inlet pipe 103 and the heat absorbing plate outlet pipe 104, and the cooling water after heat dissipation enters the heat absorbing plate through the heat absorbing plate water inlet pipe 103 101, the cooling water flow rotates...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com