Energy dissipating and slow closing type air feeding and exhausting valve

A technology of exhaust valve and valve body, which is applied in the direction of valve details, valve device, valve operation/release device, etc. It can solve the problems of shortening service life, slowing down the speed of waterproof hammer disc, and high requirements for components, so as to reduce noise, Reduces the effect of water shock and water hammer problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

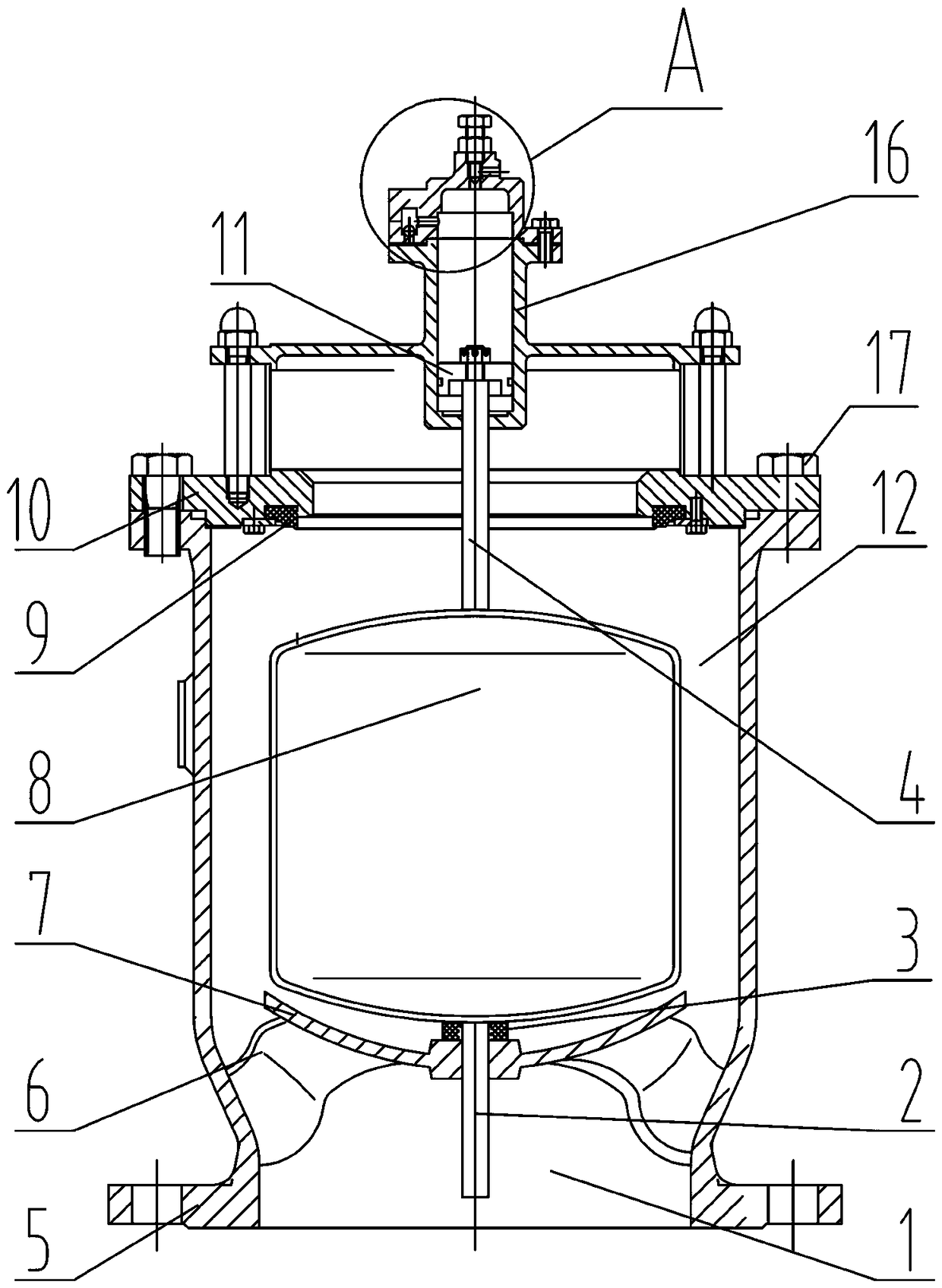

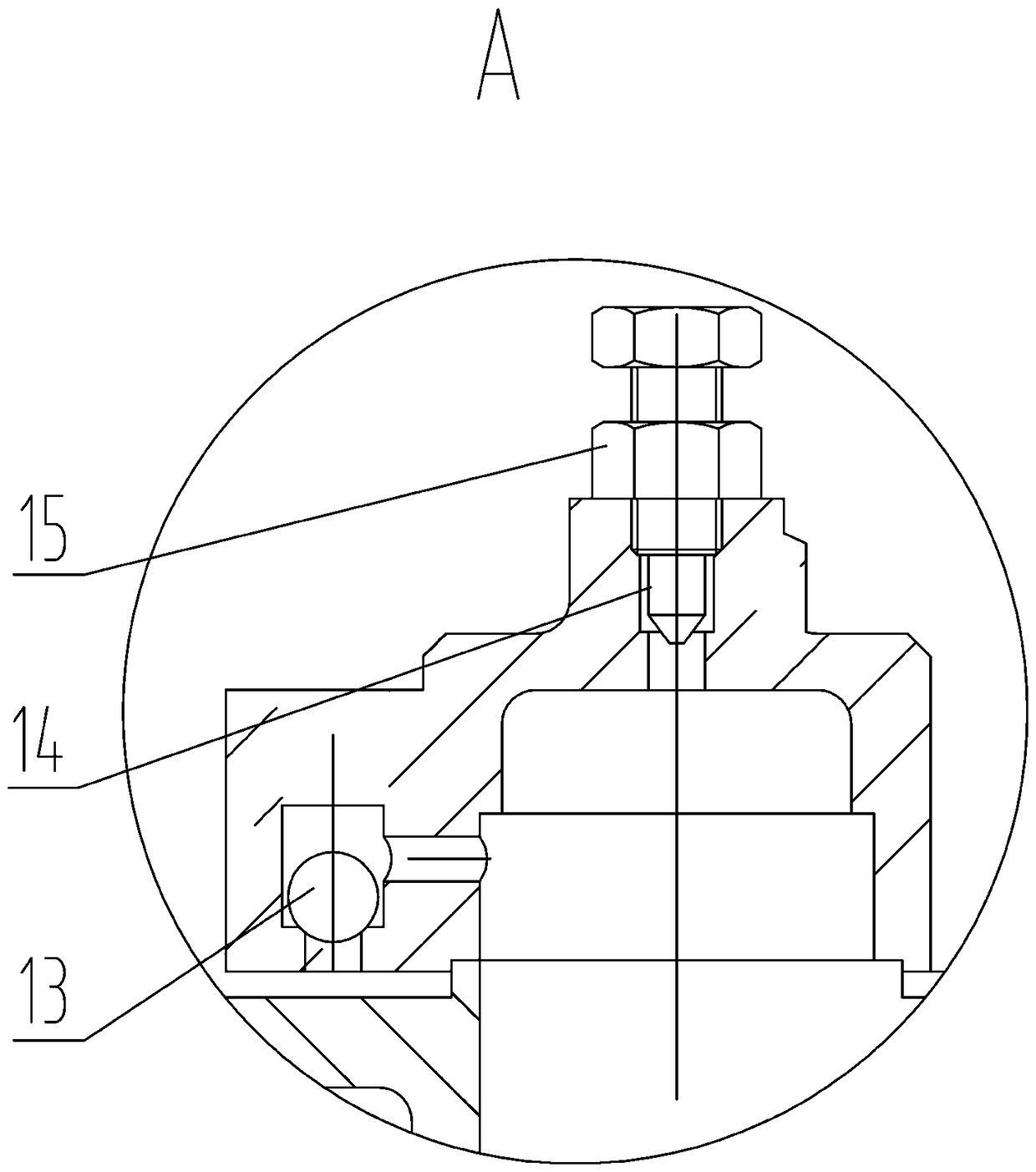

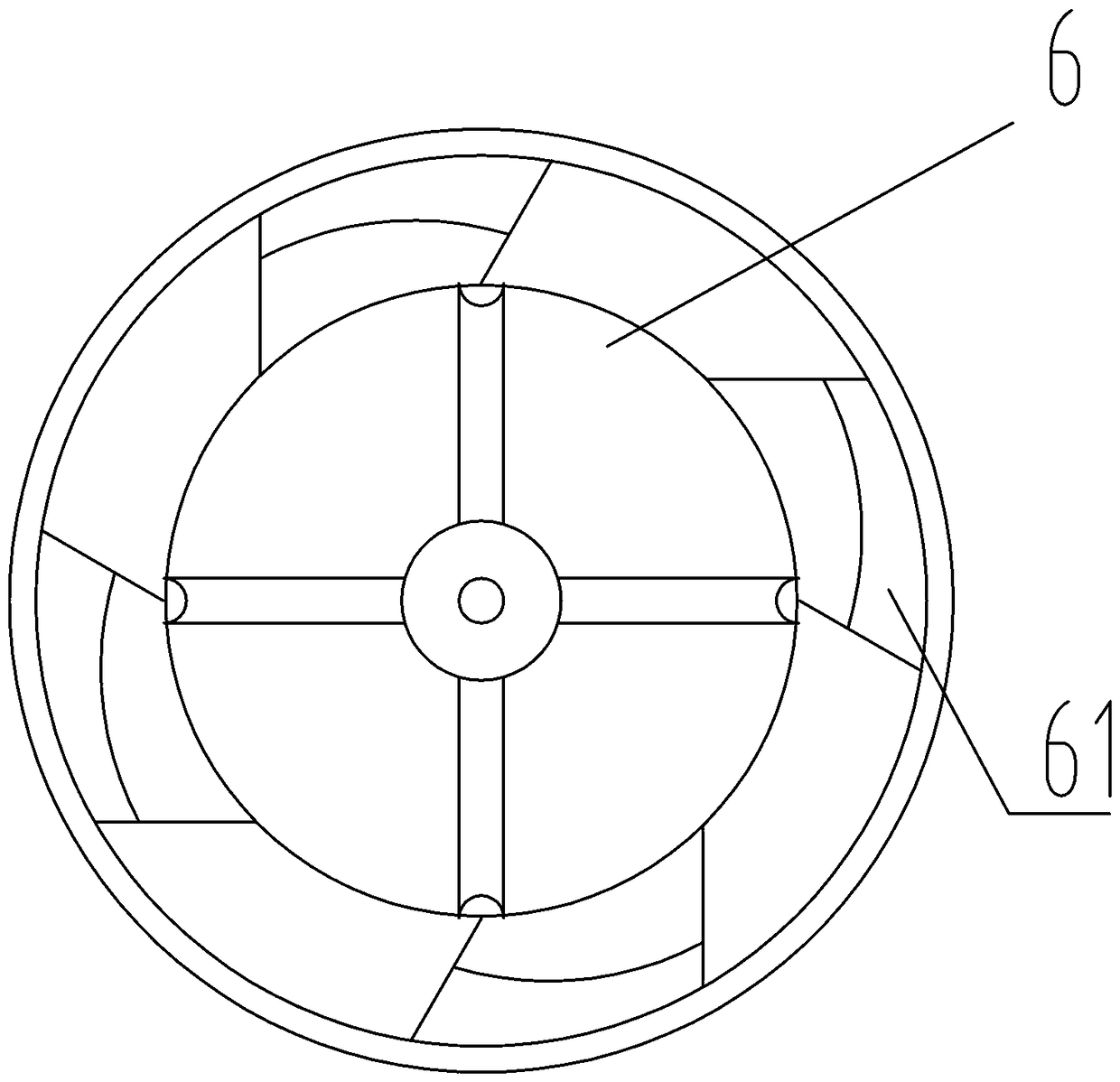

[0018] Such as Figure 1 to Figure 3 Shown, an embodiment of the present invention. An energy-dissipating slow-closing intake and exhaust valve, comprising a valve body 5, a valve cover 10 located on its upper part, and a buoy 8 that can move up and down inside the valve body 5, and is characterized in that: the valve body 5 is provided with an upstream cavity 12 and the downflow chamber 1; the downflow chamber 1 is a water inlet; the buoy 8 is located in the upflow chamber 12; the top of the buoy 8 is connected with a guide rod 4, and the guide rod 4 and the piston 11 on the top of the valve cover 10 are fixed by nuts; The piston 11 is arranged in the cylinder 16; the air-saving screw 14 is arranged on the upper part of the cylinder 16; the air-saving screw 14 is fixed with the valve cover 10 through the air-saving nut 15; the cavity on the upper side of the cylinder 16 is provided with a steel ball 13 ; The valve body 5 at the bottom of the upper chamber 12 is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com