Mooring device

A technology for mooring and bollards, applied in shipping equipment and other directions, can solve the problems that the bollards cannot be self-balanced, the number of layers of the bollards is small, and the spacing between each layer is difficult to adjust, etc., so as to achieve a simplified overall structure and strong adaptability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

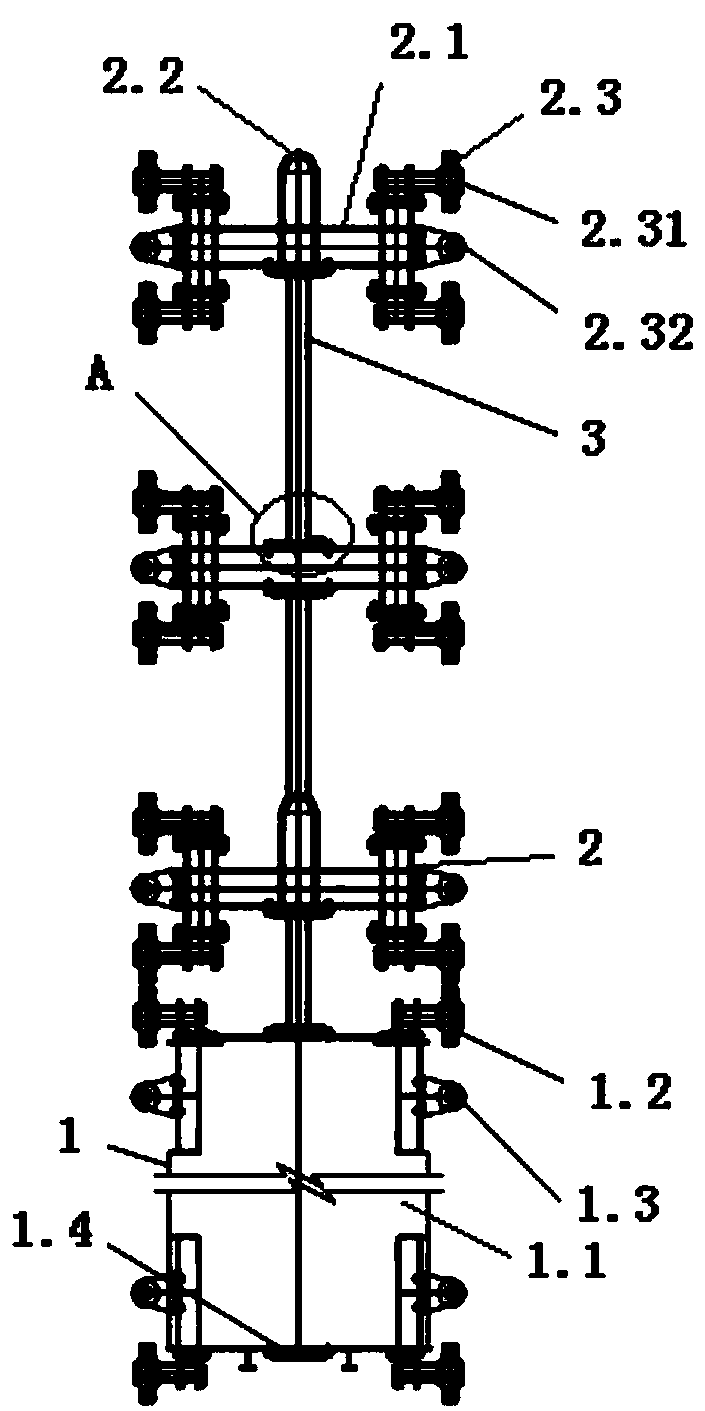

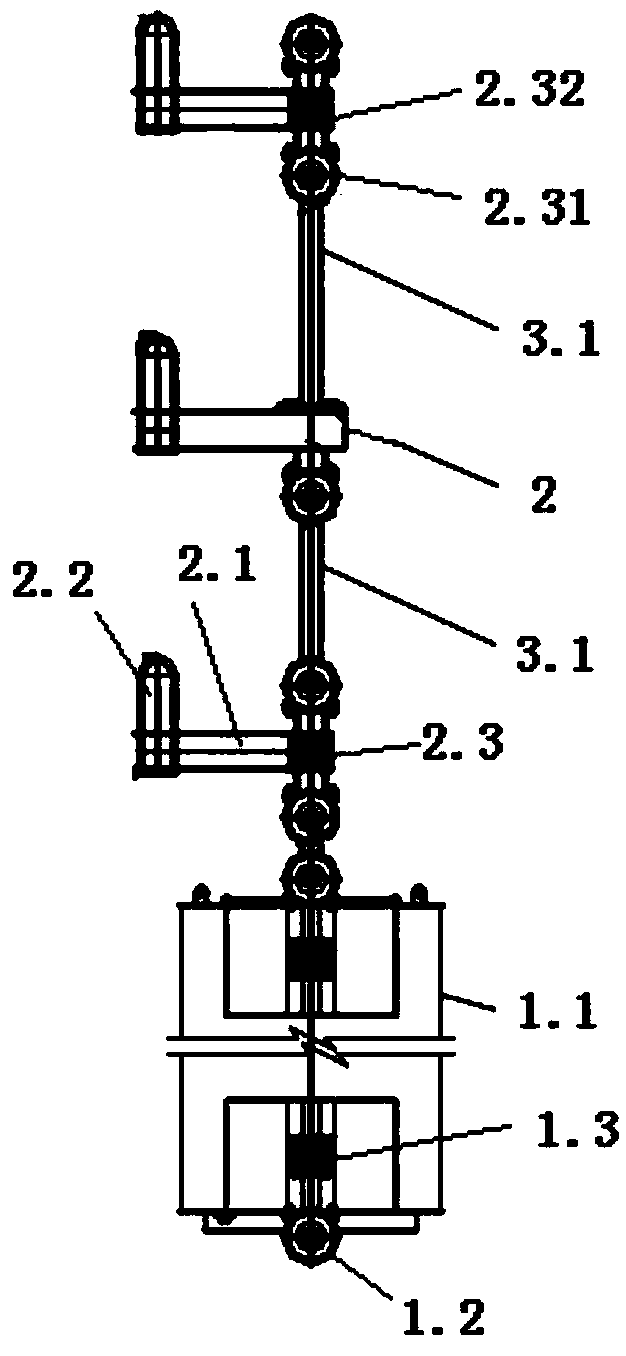

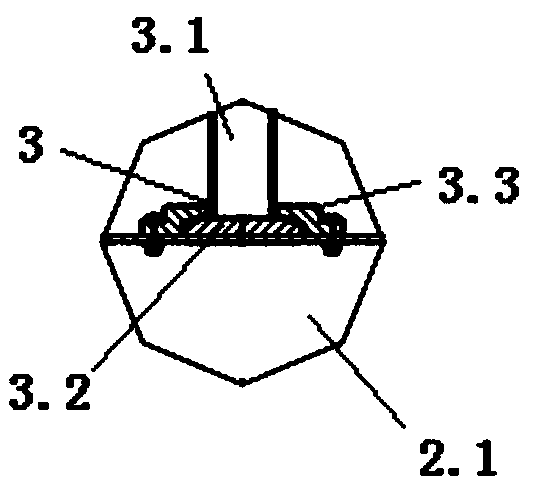

[0040] A mooring device, see figure 1 and figure 2, specifically including the buoy assembly 1, the balance mooring assembly 2 and the connector 3, the details are as follows:

[0041] The buoy assembly 1 includes a buoy 1.1, and the buoy 1.1 is provided with a reserved installation flange 1.4 for the installation of other buoys and a connection port for the installation of the connecting rod 3. The buoy 1.1 is provided with a transverse moving part 1.2 and a vertical moving part 1.3; the buoy transverse moving part 1.2 and the buoy longitudinal moving part 1.3 are matched with the track groove set arranged on the side wall of the buoy store. The horizontal moving part 1.2 of the buoy includes two sets of rollers arranged symmetrically up and down, the longitudinal moving part 1.3 of the buoy includes a set of rollers, the rolling axis of the horizontal moving part 1.2 of the buoy and the rolling axis of the longitudinal moving part 1.3 of the buoy are arranged perpendicular...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com