Method for loading primary polycrystalline silicon material and reclaimed material in production of casting monocrystals

A technology of polysilicon and recycled materials, which is applied in the directions of single crystal growth, single crystal growth, polycrystalline material growth, etc., can solve the problem of less research on the charging methods of primary polysilicon materials and recycled materials, and less research on the laying method of single crystal seed layer. Many problems, to achieve the effect of reducing production costs, reducing the risk of rupture, and reducing the outflow of silicon liquid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

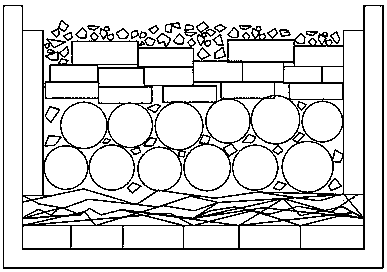

[0044] A kind of charging method of native polysilicon material and reclaimed silicon material, such as figure 1 shown, including the following steps:

[0045] In step a, a plurality of single crystal seed crystals in the shape of small cuboids are tightly laid on the bottom of the crucible G5 to form a complete single crystal seed layer, and a complete single crystal seed layer consists of 36 small cuboid single crystals Seed crystal composition, the size of the small cuboid single crystal seed crystal is 125mm×125mm×20mm.

[0046] In step b, polysilicon fragments are spread on the silicon wafer, and the thickness of the fragmented silicon wafer is 60 mm.

[0047] In step c, the side skins of four polysilicon ingots are closely attached to each side wall of the crucible, leaving a distance of 3 mm between the two side skins.

[0048] In step d, two layers of primary dense rods are stacked on the polysilicon fragments, and the primary dense rods lean against the edge skins o...

Embodiment 2

[0054] In the production of cast single crystal, a charging method of primary polysilicon material and recycled silicon material, such asfigure 1 shown, including the following steps:

[0055] Step a: Lay multiple small cuboid-shaped single crystal seed crystals closely on the bottom of the crucible G6 to form a complete single crystal seed crystal layer, and a complete single crystal seed crystal layer consists of 36 small cuboid-shaped single crystal crystals Seed crystal composition, the size of the small cuboid single crystal seed crystal is 156mm×156mm×20mm.

[0056] In step b, polysilicon fragments are spread on the silicon wafer, and the thickness of the fragmented silicon wafer is 80 mm.

[0057] In step c, the side skins of 5 polysilicon ingots are closely attached to each side wall of the crucible, leaving a distance of 4 mm between the two side skins.

[0058] In step d, two layers of primary dense rods are stacked on the polysilicon fragments, and the primary dens...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com