Method for regulating and controlling temperature of furnace top through upper part and lower part of blast furnace under oxygen-enriched condition

A furnace top temperature and furnace control technology, applied in the control field, can solve problems such as insufficient system, long reaction time of furnace conditions, unstable furnace conditions, etc., achieve the effects of optimizing furnace conditions, improving reaction dynamics, and avoiding abnormal furnace conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

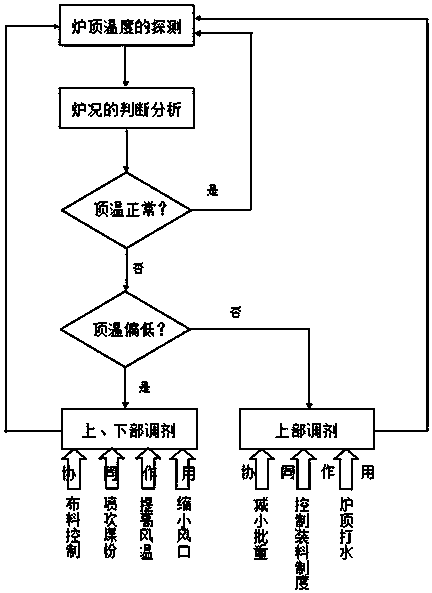

[0023] Embodiment 1: see figure 1 , a method for controlling furnace top temperature by adjusting the upper and lower parts of a blast furnace under oxygen-enriched conditions, said method comprising the following steps:

[0024] Step 1. Real-time detection of furnace top temperature;

[0025] The blast furnace roof is divided into several equidistant areas radially, and the real-time data of the roof temperature of each area is obtained through the temperature detection device installed in each area;

[0026] Step 2. Judgment and analysis of furnace conditions;

[0027] Step 3, adjusting the upper and lower parts of the blast furnace;

[0028] According to the judgment and analysis of real-time furnace conditions, when the furnace temperature is abnormal, the adjustment will be started;

[0029] Step 4, real-time information feedback;

[0030] Real-time judgment of the temperature change of the furnace top in the above-mentioned areas, enter step 2, and form a system for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com