Livestock excrement aerobic fermentation treatment system and continuous treatment method

A technology of aerobic fermentation and poultry manure, applied in the field of resource utilization, can solve the problems of long aerobic fermentation treatment time, etc., and achieve the effects of small footprint, low energy consumption, and fine material selection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

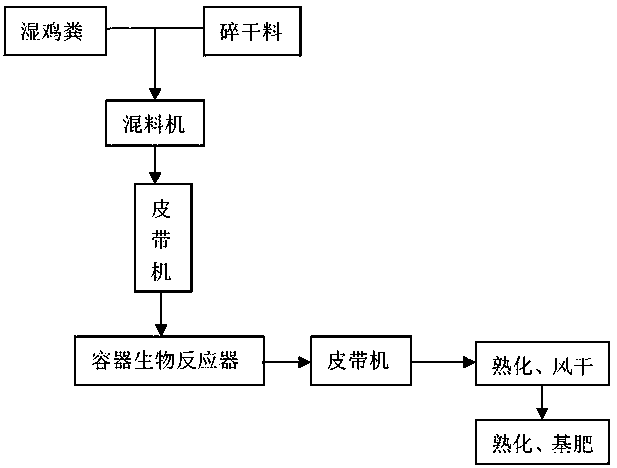

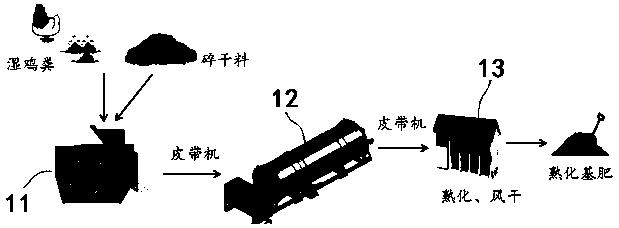

[0073] The aerobic fermentation resource treatment process of chicken manure in cages is to mix wet chicken manure and auxiliary materials (straw) at a ratio of 8:2 (that is, chicken manure with 80% weight contains 75% water and straw with 20% weight contains 15% water). The material machine is fully mixed into raw materials with a water content of 55%-65%, and is transported to the container bioreactor by a belt conveyor for aerobic fermentation. Fertilizer (C / N ratio 25-35). The process adopts a pure natural process, no external heating source, no odor release, continuous dynamic, practical operation, low energy consumption, large-scale and automatic production. Its steps:

[0074] 1. Fully mix the wet chicken manure and straw with a mixer at a ratio of 8:2 to form a fermentation raw material with a water content of 55%-65%.

[0075] 2. The fermented raw materials with water content of 50%-65% are transported to the container bioreactor through the belt conveyor for aerobi...

Embodiment 2

[0078] The aerobic fermentation resource treatment process of chicken manure in cages is to use wet chicken manure and auxiliary materials (sawdust, miscellaneous branches) in a ratio of 7.5:1:1 (that is, chicken manure with 80% weight contains 75% water and 10% weight is crushed) Sawdust with 10% water content, 10% by weight miscellaneous tree branches with 15% water content) are fully mixed with a mixer to form raw materials with a water content of 50%-65%, and are transported to the container bioreactor by a belt conveyor for aerobic fermentation. After 3 days of high-temperature aerobic fermentation treatment, it is transformed into an organic fertilizer with a water content of 45% (C / N ratio 25-35). The process adopts a pure natural process, no external heating source, no odor release, continuous dynamic, practical operation, low energy consumption, large-scale and automatic production. Its steps:

[0079] 1. Fully mix the wet chicken manure and straw with a mixer at a r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com