Device for welding 3D printing consumables and welding method of device

A technology of 3D printing and consumables, applied in the field of 3D printing, can solve the problems of complex material extraction, feeding, time-consuming and laborious, insufficient printing consumables, etc., to achieve rapid cooling, ensure safety, and improve welding efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described with the second in conjunction with the accompanying drawings.

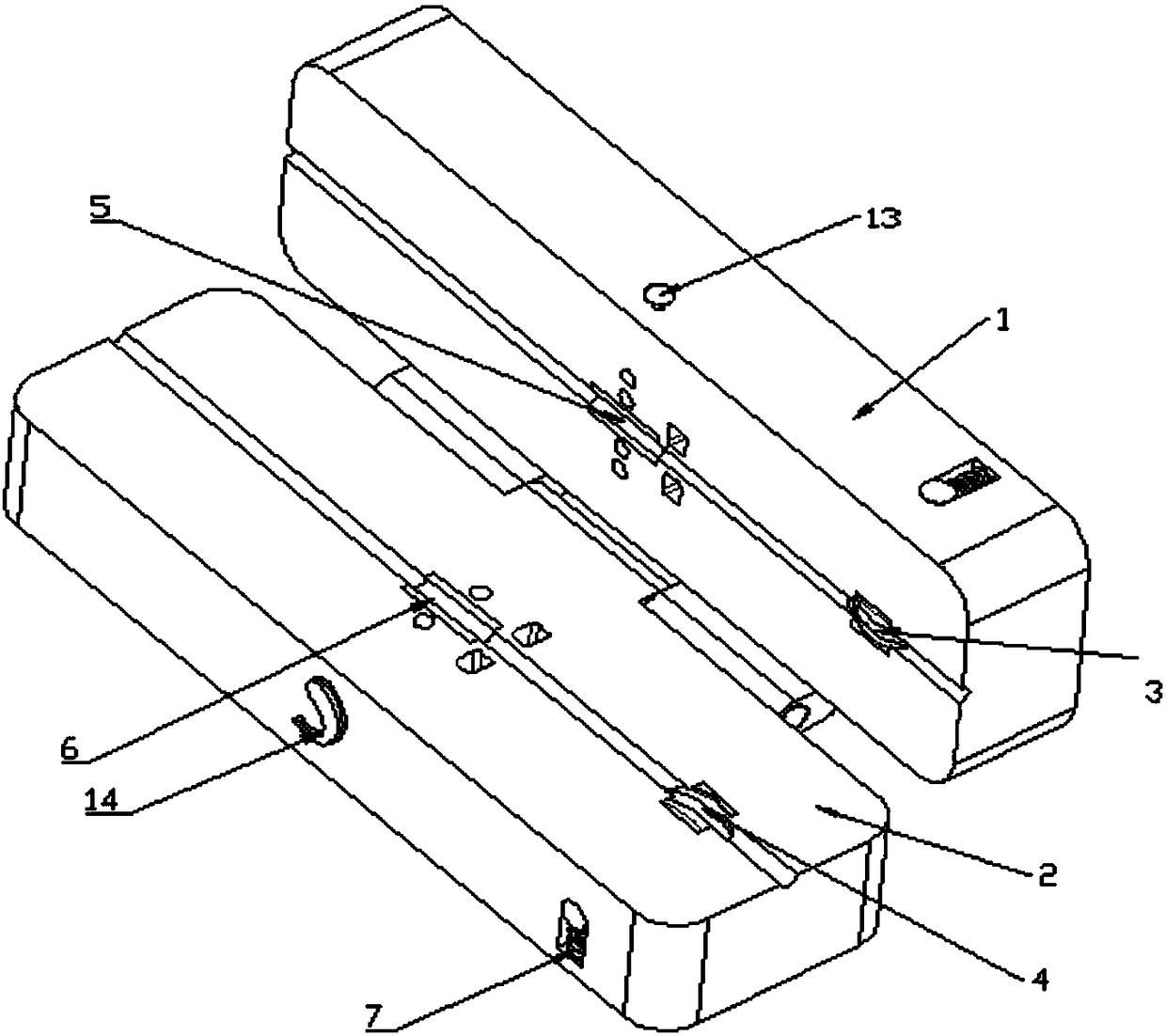

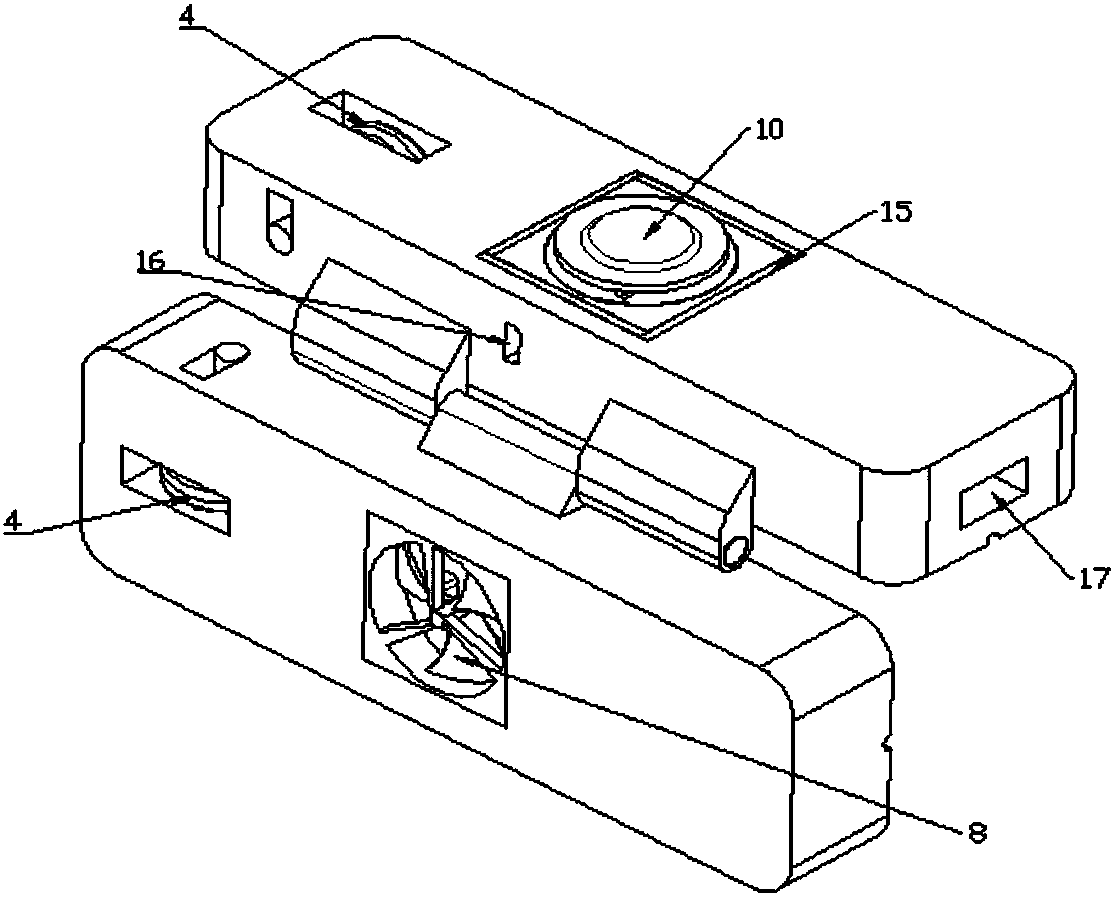

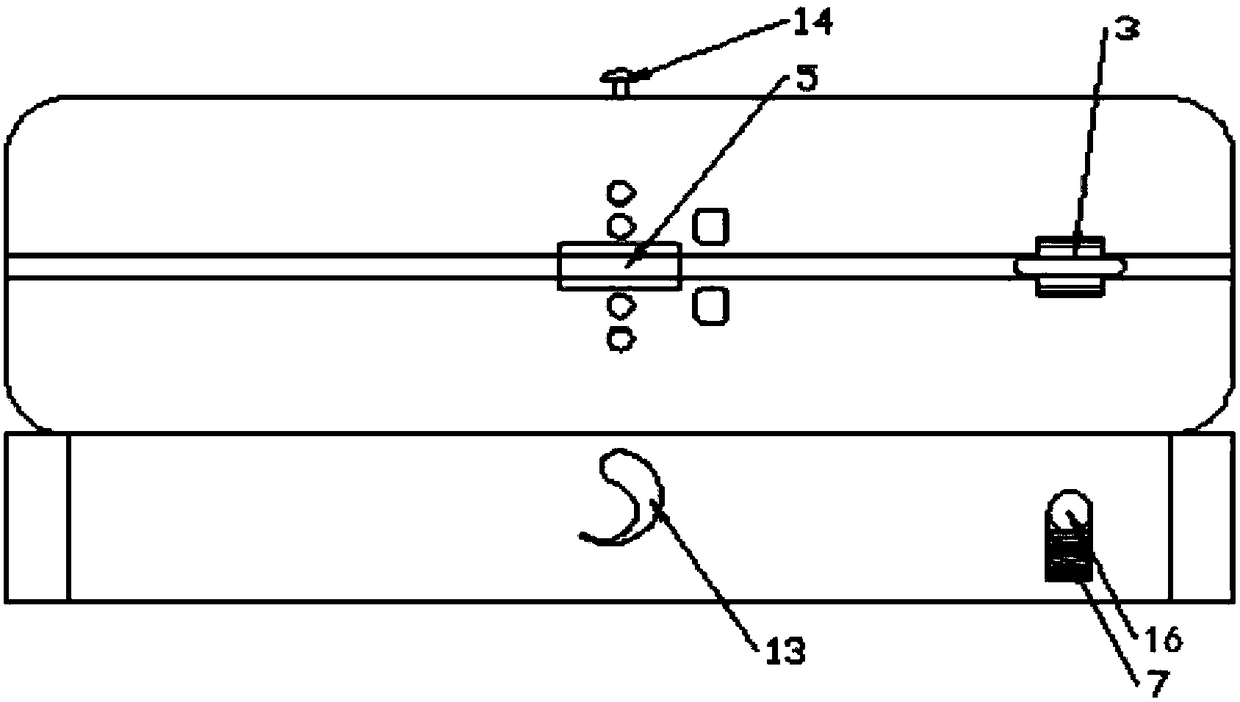

[0038] Such as figure 1 , 2 , 3, and 4, a 3D printing consumable welding device includes a first main body block 1, a second main body block 2, a first roller 3, a second roller 4, a first heat conduction block 5, a second heat conduction block 6, First extrusion spring, second extrusion spring 7, first axle, second axle 16, cooling fan 8, heat transfer block 9, pressing block 10, heating rod 11, heating return spring 12, lock, heat shield 15 and the control circuit. The first body block 1 is hinged to one side edge of the inner side of the second body block 2 through a hinge. The intersection line of the inner surface of the first main body block 1 and the inner surface of the second main body block 2 coincides with the axis of the hinge axis of the first main body block 1 and the second main body block 2 . The lock catch includes a moving lock piece 13 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com