Discharging bin for particle materials and absorption tower device with discharging bin

A granular material and silo technology, which is applied in the field of path structure design of granular material flow, can solve the problem of inconsistent discharge speed, etc., and achieve the effect of guaranteed operation effect and reliable operation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

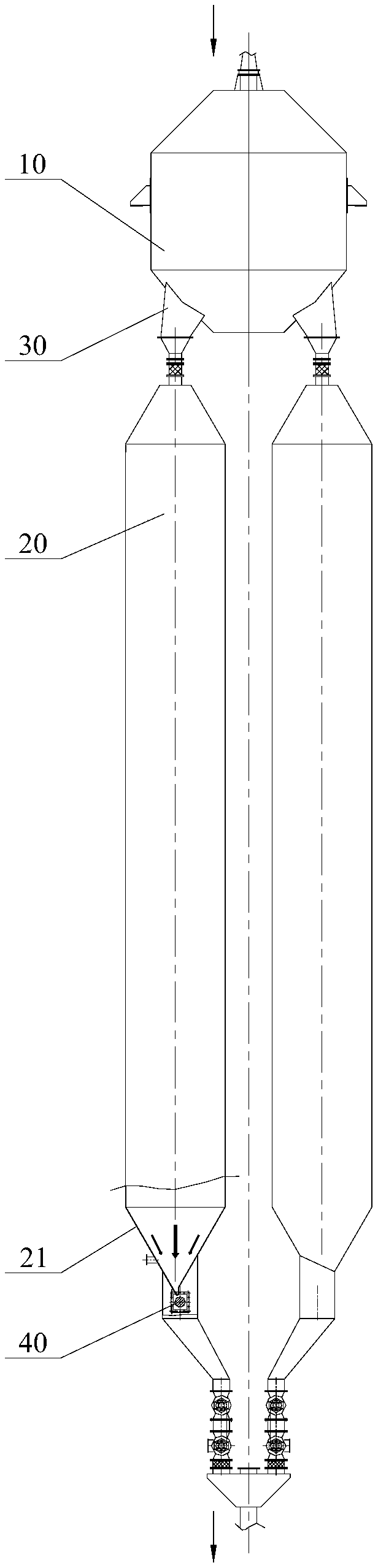

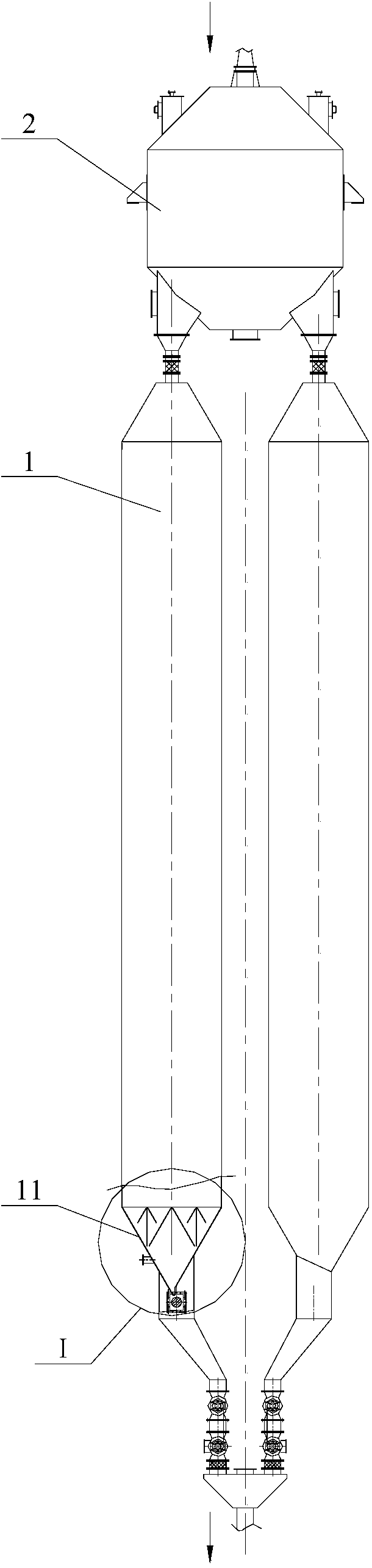

[0034] See figure 2 , which is a schematic diagram of the overall structure of the analytical tower device described in this embodiment.

[0035] The analysis tower device includes two analysis tower main bodies 1, so as to control the safety height of the tower body on the basis of satisfying the system analysis capability. The activated carbon that has been adsorbed is sent to the upper feeding bin 2 through the conveyor, and the activated carbon to be decomposed is output to the two desorption tower main bodies 1 through the feeding channel of the feeding bin 2 respectively. The same as the prior art, in the two desorption tower main bodies 1, the activated carbon in the desorption tower is indirectly heated by the heat medium, and the activated carbon is kept in the high temperature zone (320-490° C.) for a certain period of time, so that the adsorbed SO 2 Decompose and discharge harmful substances at high temperature, the adsorption function of activated carbon can be r...

Embodiment 2

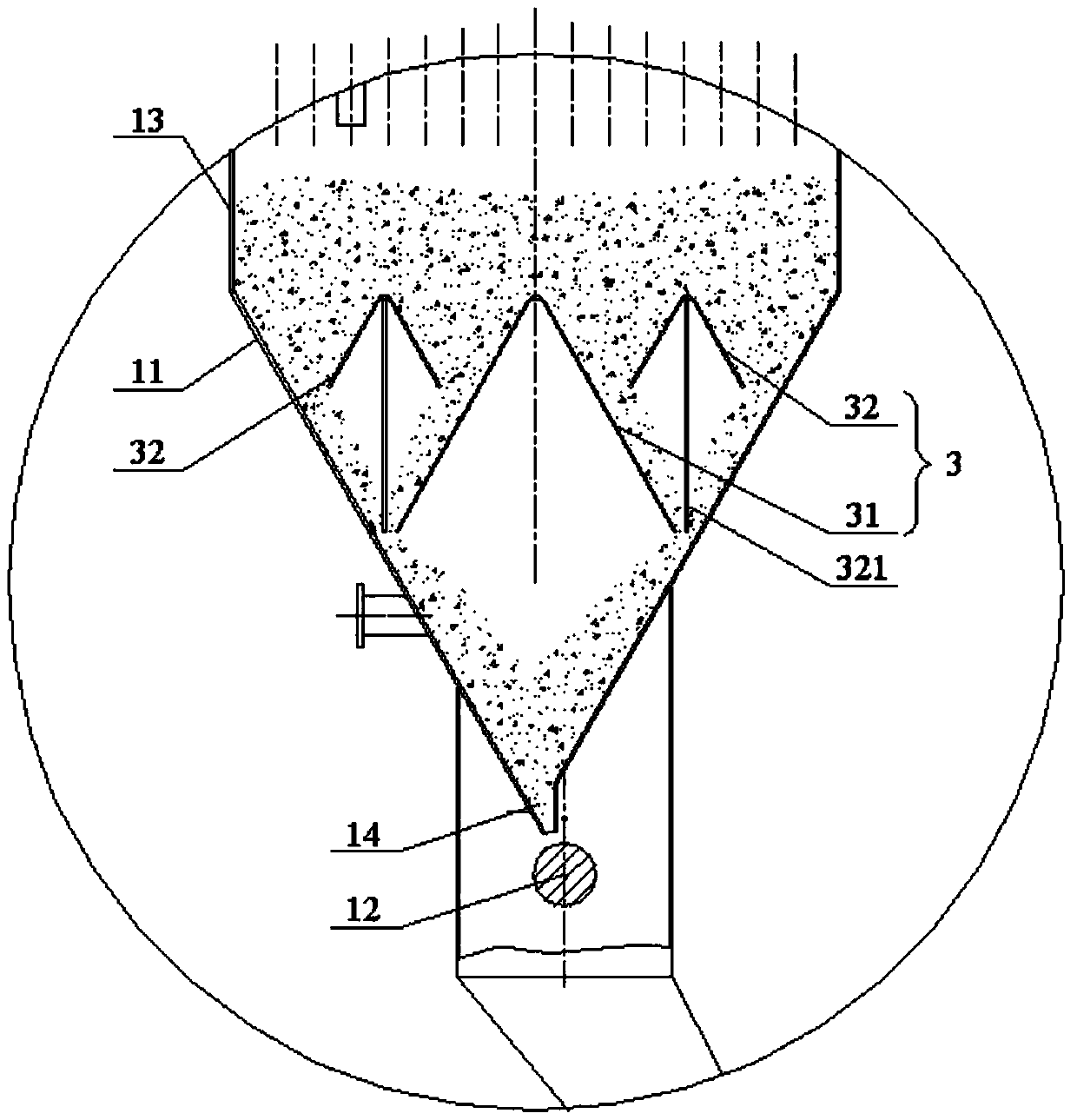

[0048] The current equalization and discharge mechanism 3 of the discharge bin provided in this embodiment is configured as a three-stage current equalization component. For details, please refer to Figure 4 , which shows a schematic structural view of the discharge bin described in this embodiment.

[0049] Compared with the first embodiment, the difference of this solution is that a third-level current equalizing part 33 is added. In order to clearly show the difference and connection between this solution and the first embodiment, components with the same function in the figure are marked with the same symbols . As shown in the figure, there are four third-level current equalization parts 33 (n=3), which are the same as the second-level current equalization parts 32, and each third-level current equalization part 33 is respectively arranged on the second-level current equalization part. The middle part of the formed parallel cavity area, thus the corresponding area is div...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com