Ceramic simulating heat-resistant and impact-resistant flowerpot and production process

A technology of impact resistance and flower pots, which is applied in gardening, application, coating, etc., can solve the problems of complex structure, large space occupancy, and difficulty in handling, etc., achieve good heat resistance, improve decoration, and facilitate handling Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

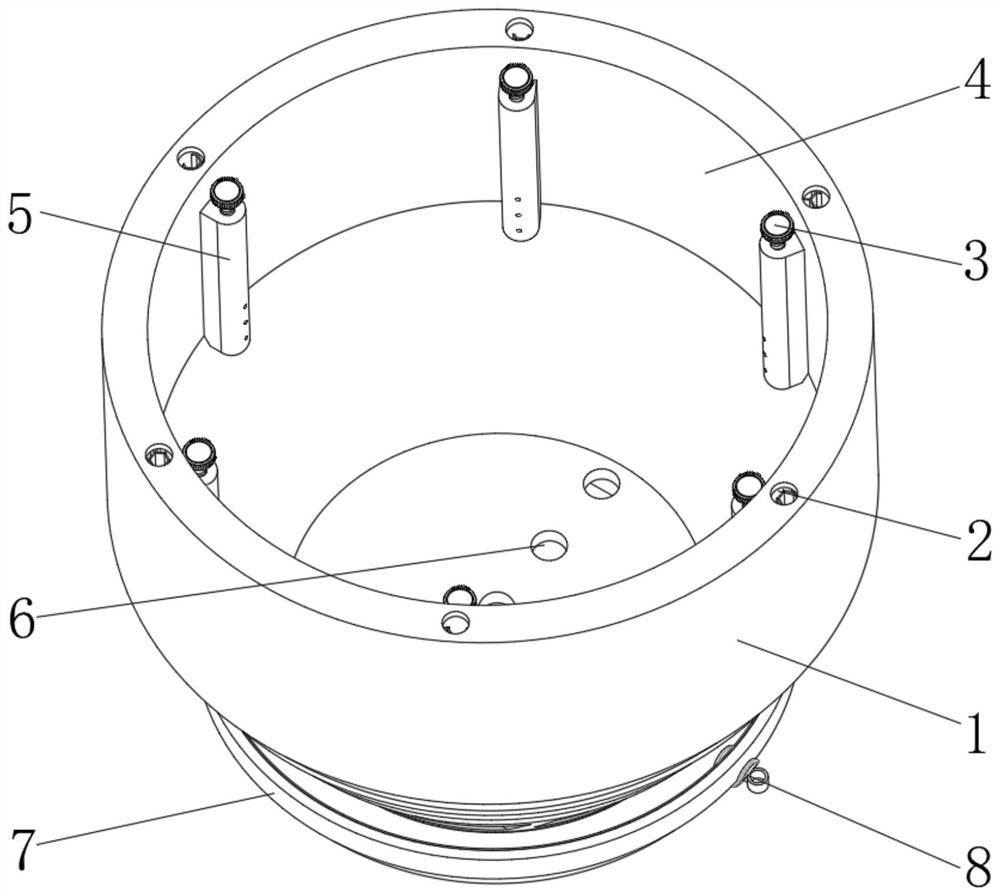

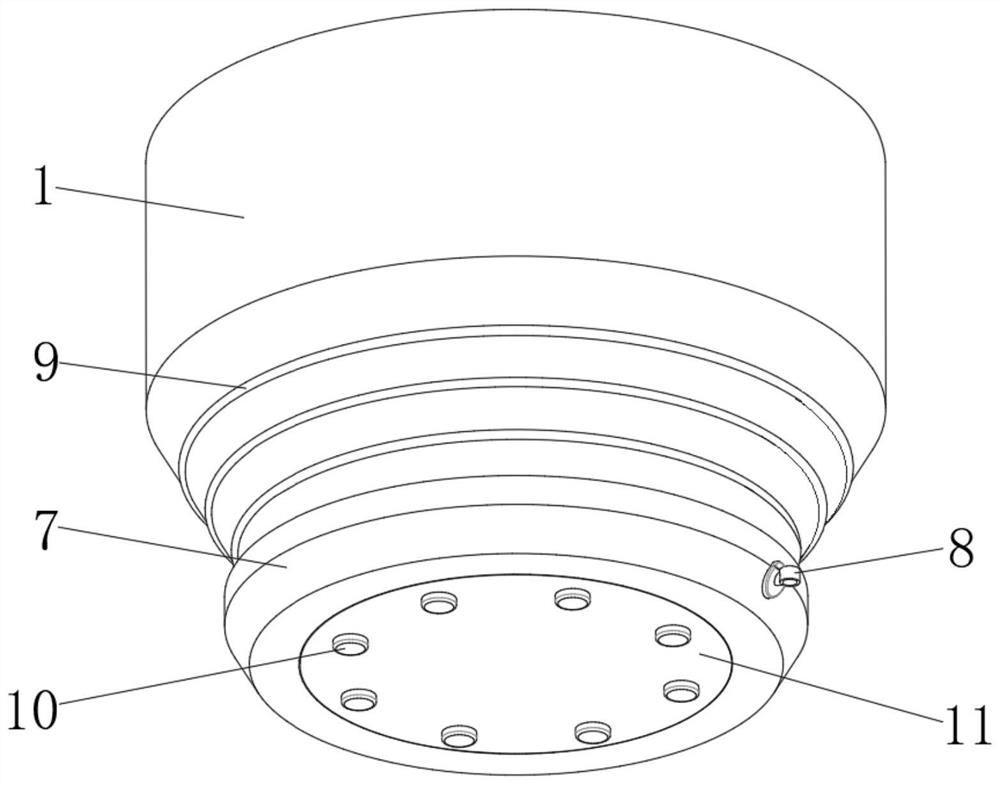

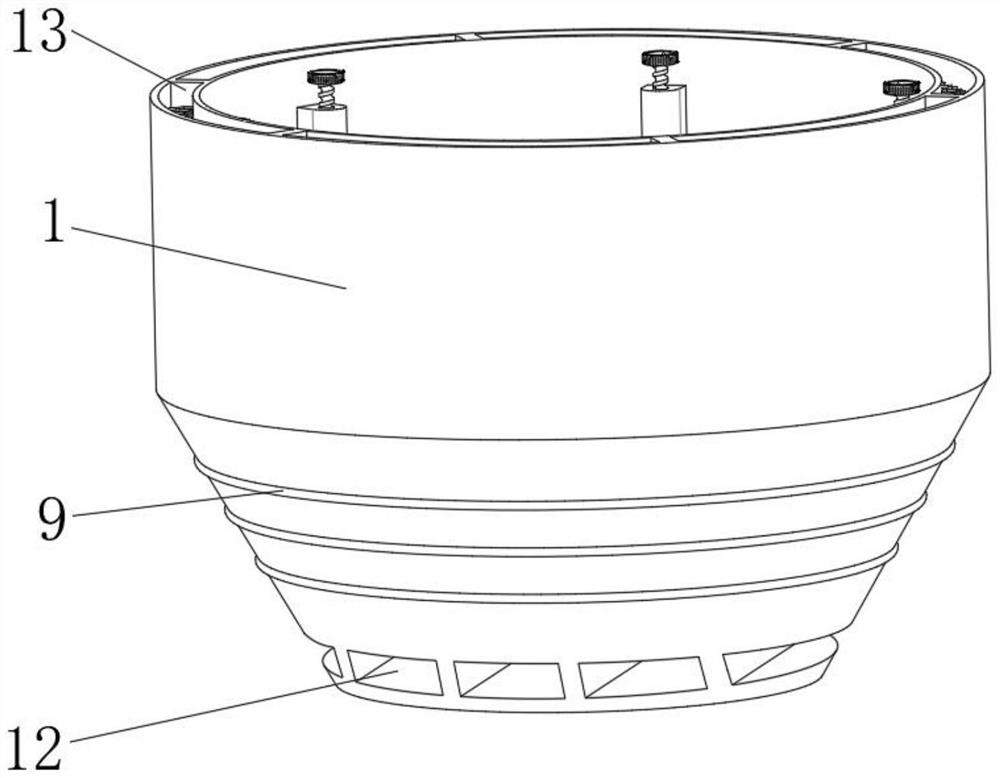

[0043] A melamine heat-resistant impact-resistant flower pot, such as Figure 1-5 As shown, it includes a main body 1, the main body 1 is provided with an accommodating cavity 4 inside, a water storage chamber is opened inside the side wall of the main body 1, and ribs 13 uniformly distributed in the side wall of the main body 1 are integrally arranged on the inside of the main body 1, and the main body 1 The outer wall of the top is provided with evenly distributed water inlets 2, and the water inlets 2 correspond to the positions of the water storage chambers and are connected to each other; the inner wall of the main body 1 is bonded with regulating chambers 5 distributed uniformly around the circumference, between the regulating chamber 5 and the water storage chamber. The first water outlet hole 16 of linear distribution is processed in between, and the second water outlet hole 19 of linear distribution is processed on the outer wall of one side of the adjustment chamber 5...

Embodiment 2

[0053] A production process of an imitation porcelain heat-resistant and impact-resistant flower pot, the preparation of its main body 1 includes the following steps:

[0054] S1: 40-50 parts by weight of polypropylene, 10-15 parts of flax fiber, 3-5 parts of PP toughening agent, 2-3 parts of PP flame retardant, 5-10 parts of stabilizer, 5-5 parts of antioxidant 10 parts, 5-10 parts of polyol benzoate, 3-5 parts of deodorant; and mix well;

[0055] S2: Stir with a high-speed mixer, put it into a heating box at 210°C-230°C and heat at high temperature to melt the mixture;

[0056] S3: put the flower pot raw material into the injection molding machine, heat and melt it with the injection molding machine and put it into the already made flower pot mold;

[0057] S4: cooling the flower pot mold to obtain a semi-finished product of the flower pot;

[0058] S5: Spraying an imitation porcelain finish paint on the whole flowerpot to obtain a finished product.

Embodiment 3

[0060] A production process of an imitation porcelain heat-resistant and impact-resistant flower pot, the preparation of its main body 1 includes the following steps:

[0061] S1: By weight, take 48 parts of polypropylene, 14 parts of flax fiber, 5 parts of PP toughening agent, 3 parts of PP flame retardant, 8 parts of stabilizer, 8 parts of antioxidant, 8 parts of polyol benzoate, 4 parts of deodorant; and mix well;

[0062] S2: Stir with a high-speed mixer, put it into a heating box at 220°C and heat at high temperature to melt the mixture;

[0063] S3: put the flower pot raw material into the injection molding machine, heat and melt it with the injection molding machine and put it into the already made flower pot mold;

[0064] S4: cooling the flower pot mold to obtain a semi-finished product of the flower pot;

[0065] S5: Spraying an imitation porcelain finish paint on the whole flowerpot to obtain a finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com