Magnetic beam powder type powder feeding device for laser additional material manufacturing

A laser additive and powder feeding device technology, applied in the direction of additive manufacturing, additive processing, process efficiency improvement, etc., can solve the problem of powder flow divergence, achieve the effect of improving convergence, reducing cost, and improving molding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

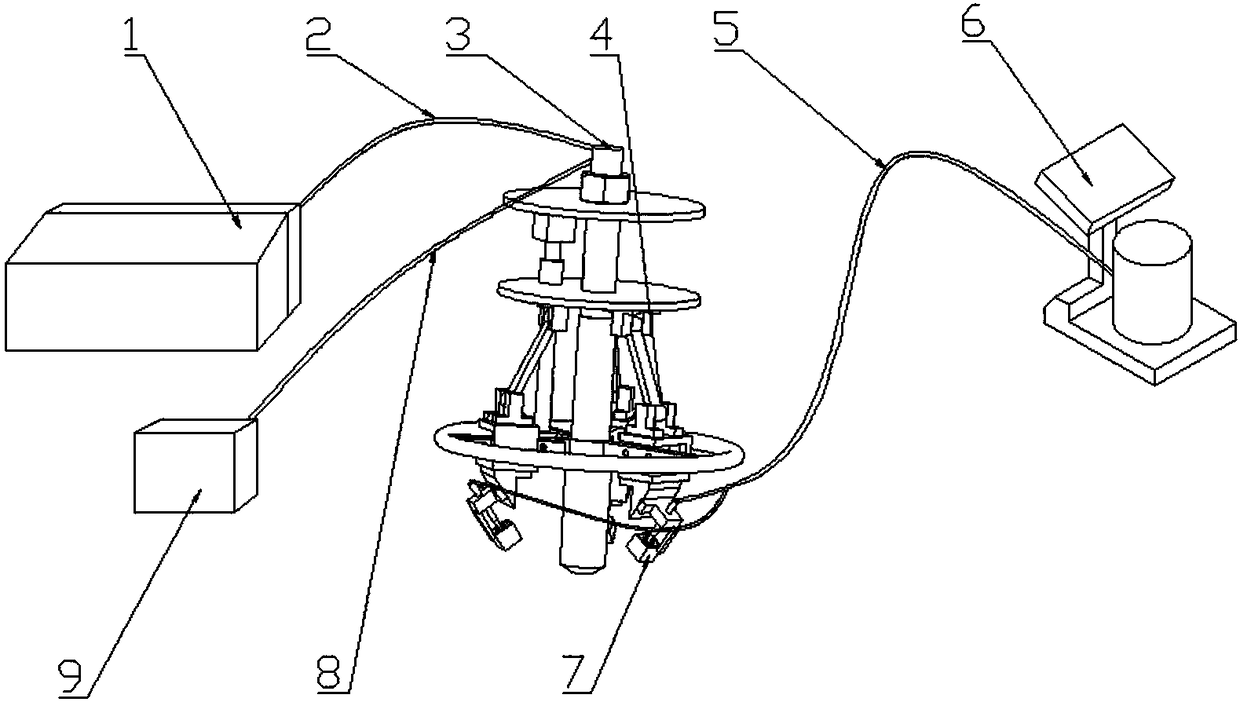

[0028] Embodiment 1 A magnetic beam powder feeding device for laser additive manufacturing according to the present invention includes:

[0029] frame;

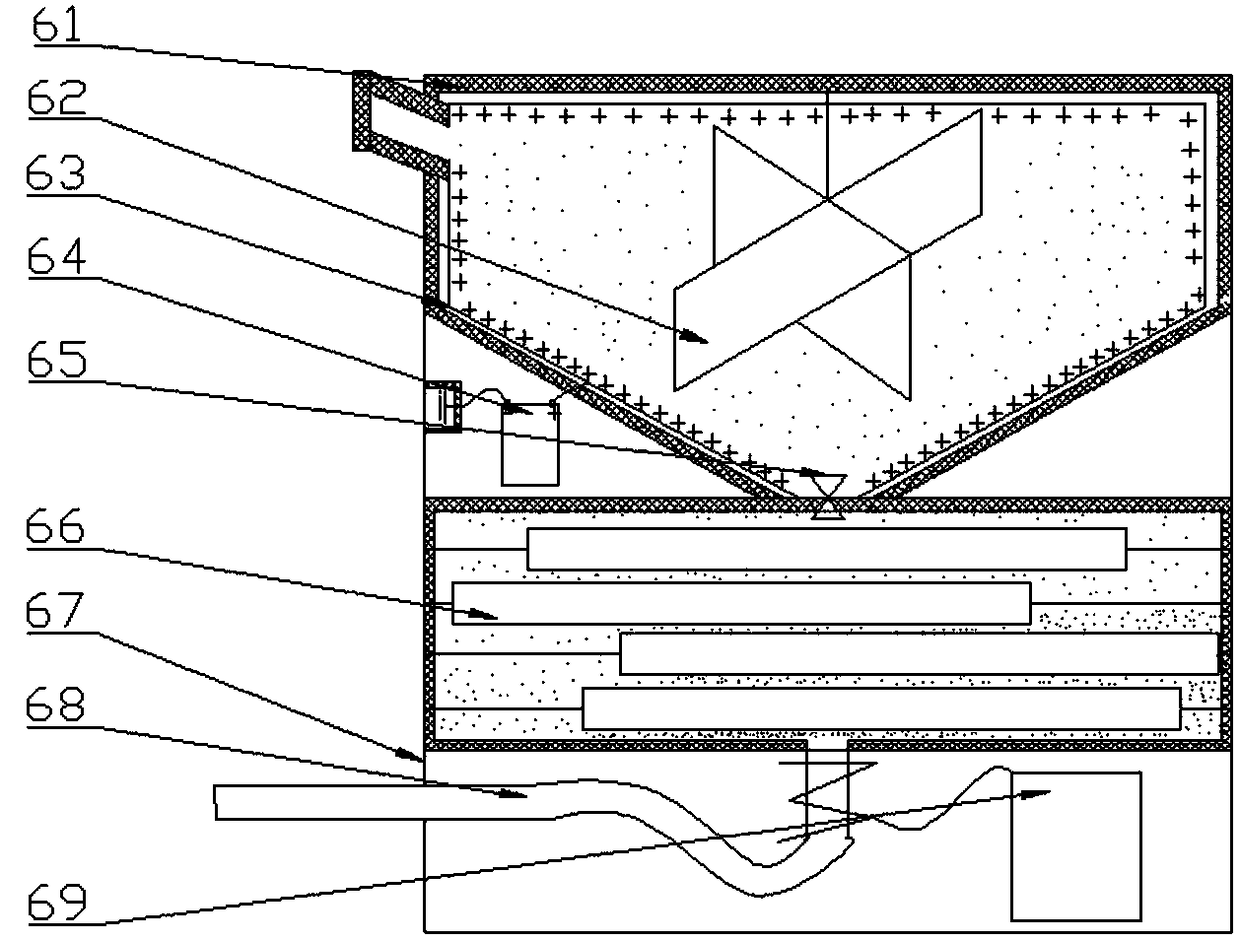

[0030] The powder charging device 6 includes a charging unit for charging the powder and a powder feeding unit for conveying the charged powder, wherein the charging unit is arranged at the upstream powder inlet of the powder pipe, and the powder pipe of the powder feeding unit is downstream of the powder outlet The mouth is set at the lower part of the frame body through the powder pipe position adjustment device;

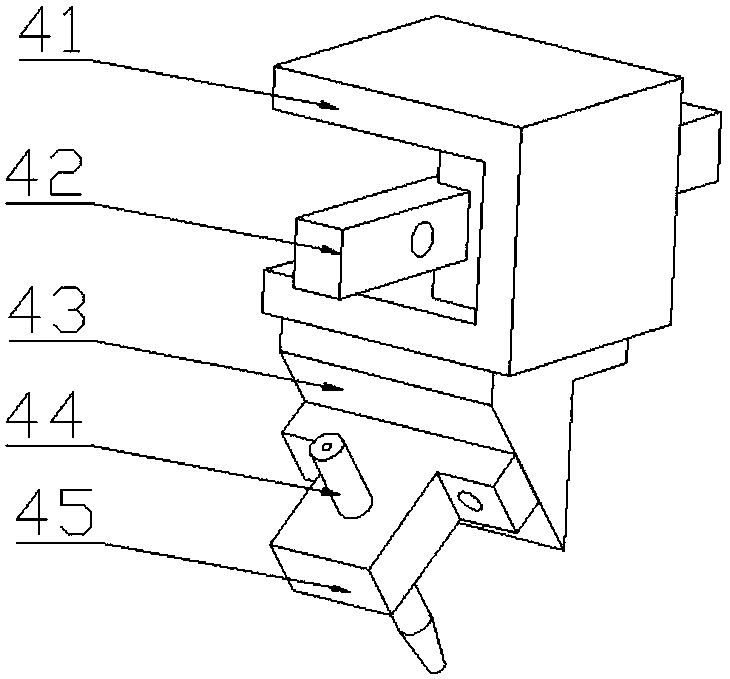

[0031] The powder tube position adjustment device 4 is arranged at the lower part of the frame body along the circumferential direction, and is used to adjust the position of the powder outlet downstream of the powder tube so that the powder and the laser emitted by the laser emitting unit converge;

[0032] The magnetic beam powder device 7 is equipped at the powder outlet downstream of the powder pipe, and has...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com