A tobacco humectant

A humectant and tobacco technology, applied in the directions of tobacco, tobacco processing, application, etc., can solve the problems of easy damping of cigarettes, maintenance of moisture content of finished cigarettes and poor improvement of smoking comfort, etc. Water retention effect, strong bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

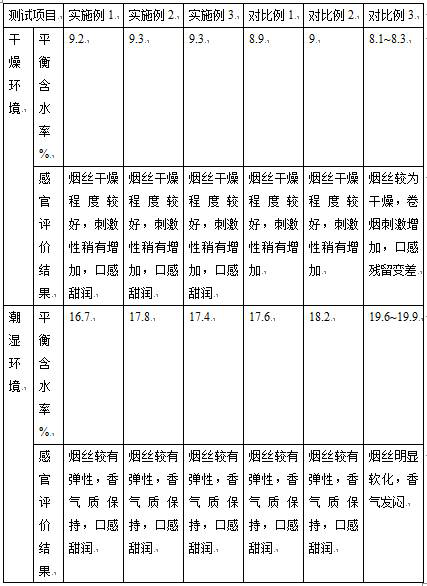

Examples

preparation example Construction

[0022] The preparation method of mouthfeel accelerator, comprises the steps:

[0023] (1) Take potassium hydroxide and add anhydrous methanol at a mass ratio of 1:10, stir magnetically for 30-50 minutes, then add L-potassium aspartate 2-4 times the mass of potassium hydroxide, stir and mix at 25-30°C 30~40min to get the stirred mixture, take the stirred mixture and add anhydrous methanol and D-fructose according to the mass ratio of 20:50:3, stir and mix at 50~60℃ for 2~3h, cool to room temperature, concentrate under reduced pressure to get the concentrate , take the concentrate and add absolute ethanol according to the mass ratio of 3:2, and let it stand for 1~2h to obtain a precipitate;

[0024] (2) Take the precipitate and add anhydrous methanol at a mass ratio of 1:10, stir and mix for 20-30 minutes, then add 15-20% acetic acid of the precipitate, stir and mix at 40-50°C for 1-2 hours, and cool to 0-5 ℃, to obtain a cooling product, take the cooling product and add absolu...

Embodiment 1

[0027] Sunflower oil residue: obtained from Shihezi Huichang Grain and Oil Co., Ltd.

[0028] Moisture-retaining active agent: a. Remove the core of pear, homogenate, take the homogenate and add absolute ethanol at a mass ratio of 1:3, stir and mix at 40°C for 2 hours, then ultrasonicate at 200W and 50°C for 20min to obtain the mixture, centrifuge, Take the supernatant and rotatively evaporate to get the rotovap. Take the rotoevaporator and add hexadecyltrimethylammonium bromide at a mass ratio of 20:1, and let it stand at 25°C for 15 hours to get the still thing. Take the still thing according to Add a sodium chloride solution with a concentration of 0.4mol / L at a mass ratio of 2:3, take the upper layer and add absolute ethanol at a mass ratio of 1:3, and let it stand at 2°C for 12 hours to obtain a precipitate a;

[0029]b. Take the precipitate a and add it to dimethyl sulfoxide at a mass ratio of 1:15, and stir and mix at 40°C for 20 minutes to obtain mixture a. In parts by...

Embodiment 2

[0036] Sunflower oil residue: obtained from Shihezi Huichang Grain and Oil Co., Ltd.

[0037] Moisture-retaining active agent: a. Remove the core of pear, homogenate, take the homogenate and add absolute ethanol at a mass ratio of 1:3, stir and mix at 50°C for 3h, then ultrasonicate at 200W and 60°C for 30min to obtain the mixture, centrifuge, Take the supernatant and rotatively evaporate to get the rotovap. Take the rotoevaporator and add hexadecyltrimethylammonium bromide according to the mass ratio of 20:1. Let it stand at 30°C for 18h to get the still thing. Take the still thing according to Add a sodium chloride solution with a concentration of 0.4mol / L at a mass ratio of 2:3, take the upper layer and add absolute ethanol at a mass ratio of 1:3, and let it stand at 4°C for 15 hours to obtain a precipitate a;

[0038] b. Take the precipitate a and add it to dimethyl sulfoxide at a mass ratio of 1:15, and stir and mix at 50°C for 30 minutes to obtain mixture a. In parts by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com