Dust collector for rice flour milling

A technology of dust collector and fried rice, applied in application, food science, food processing, etc., can solve the problems of limited dust removal area, poor dust removal efficiency, inability to sieve, etc., to achieve better taste, stable operation, and quick response.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following is further described in detail through specific implementation methods:

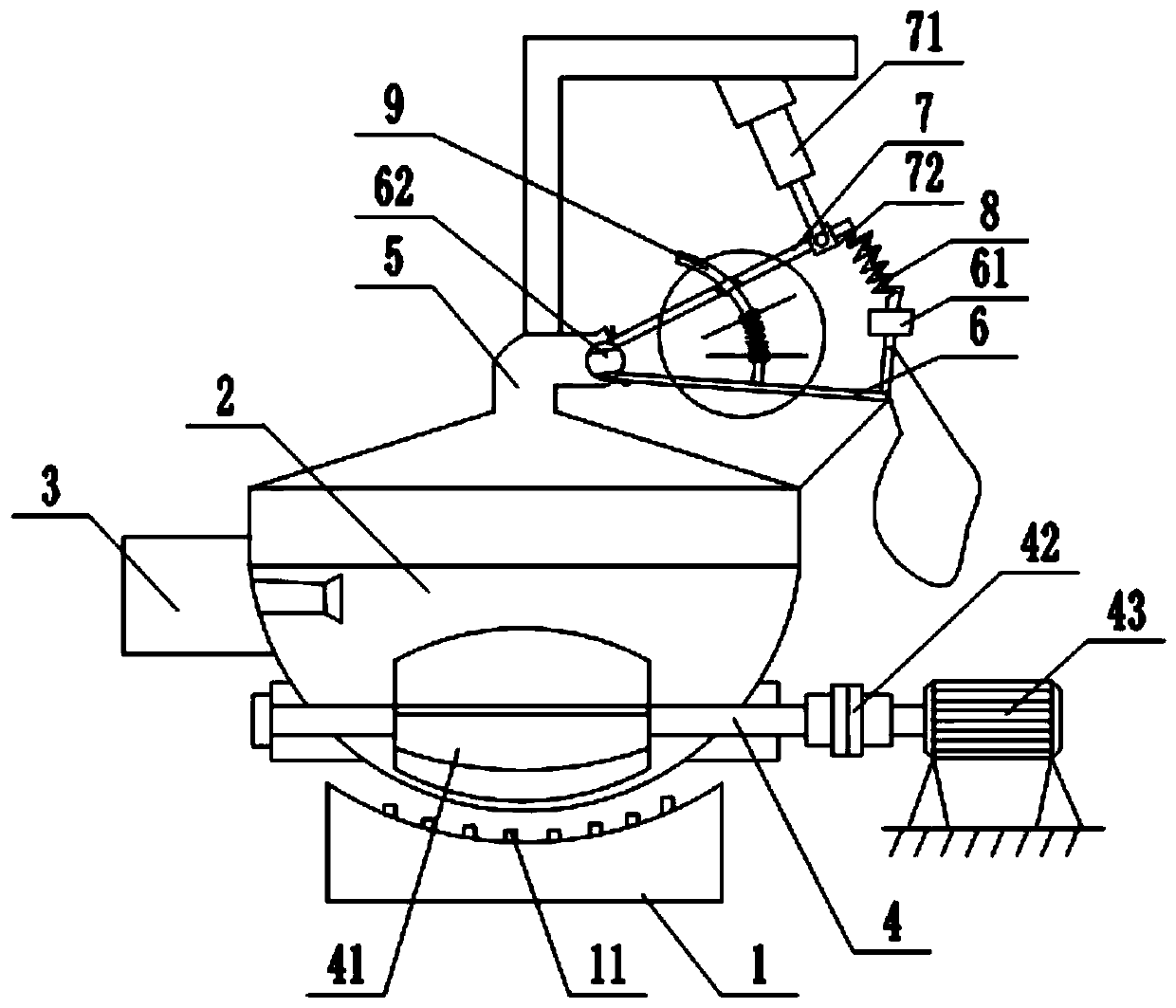

[0018] The reference signs in the drawings of the description include: heater 1, flame sprayer 11, pot body 2, fan 3, rotating shaft 4, fan blade 41, clutch 42, motor 43, dust discharge pipe 5, first folding plate 6, second A one-way valve 61, a second one-way valve 62, a second folding plate 7, a hydraulic cylinder 71, a slider 72, a corrugated curtain 8, an arc-shaped sliding rod 9, a vibrating plate 91, and a sleeve 92.

[0019] The embodiment is basically as attached figure 1 Shown:

[0020] The dedusting machine for rice flour milling is mainly composed of a pot body 2, a heater 1 and a dust removal mechanism. The pot body 2 is installed above the heater 1, and the dust removal mechanism is installed on the upper end of the pot body 2. 2 is connected with a rotating shaft 4 for rotation, and a plurality of fan blades 41 are fixedly connected to the rotating shaft 4. One end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com