Aluminum nitride embedded PCB substrate and manufacturing method thereof

A technology of an aluminum nitride substrate and a manufacturing method, which is applied to the manufacture of printed circuits, the manufacture of printed circuit precursors, printed circuit components, etc. Low problems, to avoid environmental problems, prevent dents or fracturing, save steps for titanium removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

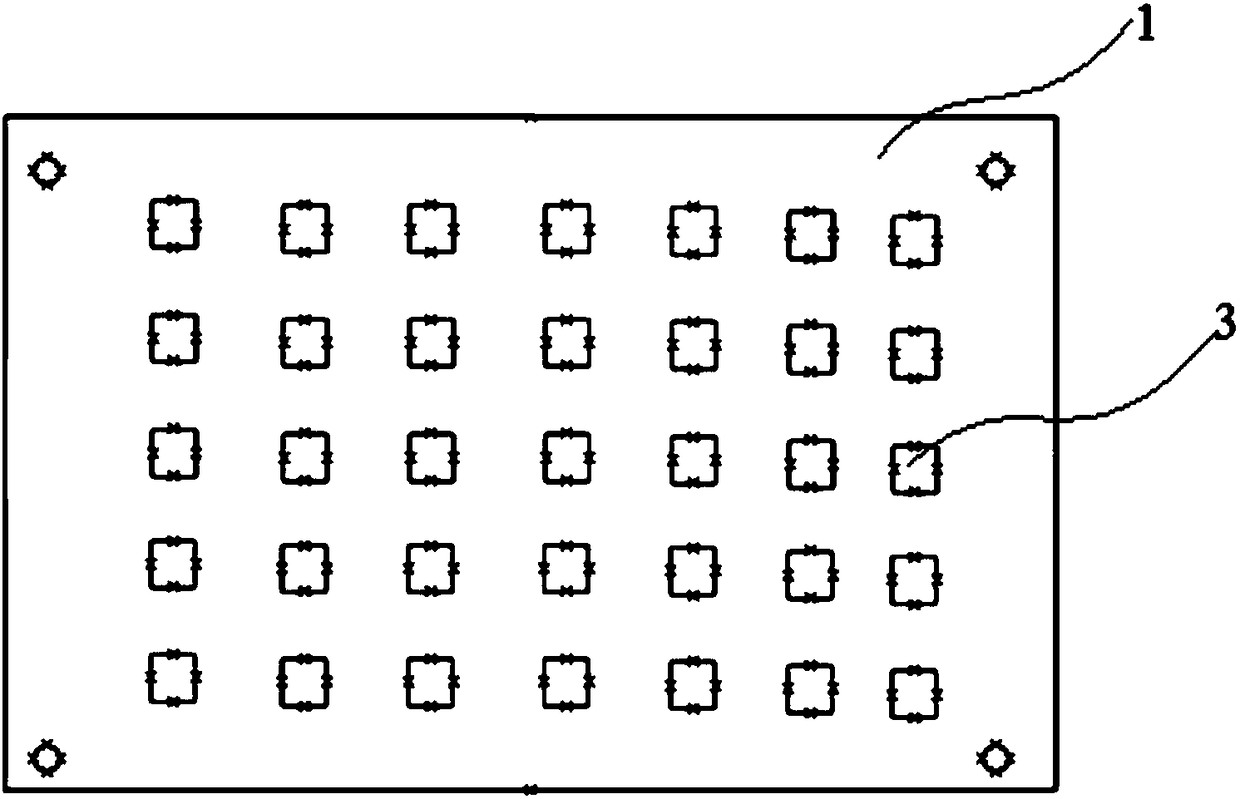

[0033] This embodiment provides an embedded aluminum nitride PCB substrate, such as Figure 1-2 As shown, the embedded aluminum nitride PCB substrate includes a rigid substrate 1, the rigid substrate 1 is an FR4 board, and the rigid substrate 1 is provided with a storage tank 2, and the storage tank 2 is provided with aluminum nitride Block 3, as shown in the figure, the bottom surface of the aluminum nitride block 3 is attached to the bottom surface of the storage tank 2, and the height difference between the top surface of the aluminum nitride block 3 and the top surface of the rigid substrate 1 is not more than 20 μm. It is convenient to assemble the aluminum nitride block 3 , and the distance between the aluminum nitride block 3 and the inner sidewall of the accommodating groove 2 is 50 μm.

[0034] Further, the top surface and the bottom surface of the aluminum nitride block 3 are sequentially provided with a conductive layer 4 and a copper plating layer 5 along a directi...

Embodiment 2

[0036] This embodiment provides an embedded aluminum nitride PCB substrate, such as Figure 1-2 As shown, the embedded aluminum nitride PCB substrate includes a rigid substrate 1, the rigid substrate 1 is an FR4 board, and the rigid substrate 1 is provided with a storage tank 2, and the storage tank 2 is provided with aluminum nitride Block 3, as shown in the figure, the bottom surface of the aluminum nitride block 3 is attached to the bottom surface of the storage tank 2, and the height difference between the top surface of the aluminum nitride block 3 and the top surface of the rigid substrate 1 is not more than 20 μm. It is convenient to assemble the aluminum nitride block 3 , and the distance between the aluminum nitride block 3 and the inner sidewall of the accommodating groove 2 is 100 μm.

[0037] Further, the top surface and the bottom surface of the aluminum nitride block 3 are sequentially provided with a conductive layer 4 and a copper plating layer 5 along the dire...

Embodiment 3

[0039] This embodiment provides an embedded aluminum nitride PCB substrate, such as Figure 1-2As shown, the embedded aluminum nitride PCB substrate includes a rigid substrate 1, the rigid substrate 1 is an FR4 board, and the rigid substrate 1 is provided with a storage tank 2, and the storage tank 2 is provided with aluminum nitride Block 3, as shown in the figure, the bottom surface of the aluminum nitride block 3 is attached to the bottom surface of the storage tank 2, and the height difference between the top surface of the aluminum nitride block 3 and the top surface of the rigid substrate 1 is not more than 20 μm. It is convenient to assemble the aluminum nitride block 3 , and the distance between the aluminum nitride block 3 and the inner sidewall of the accommodating groove 2 is 80 μm.

[0040] Further, the top surface and the bottom surface of the aluminum nitride block 3 are sequentially provided with a conductive layer 4 and a copper plating layer 5 along a directio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com