Time difference model-based soft measurement modeling method

A time difference and modeling method technology, applied in CAD numerical modeling, special data processing applications, instruments, etc., can solve problems such as spending a lot of time, reducing factory operating efficiency, and offsetting.

- Summary

- Abstract

- Description

- Claims

- Application Information

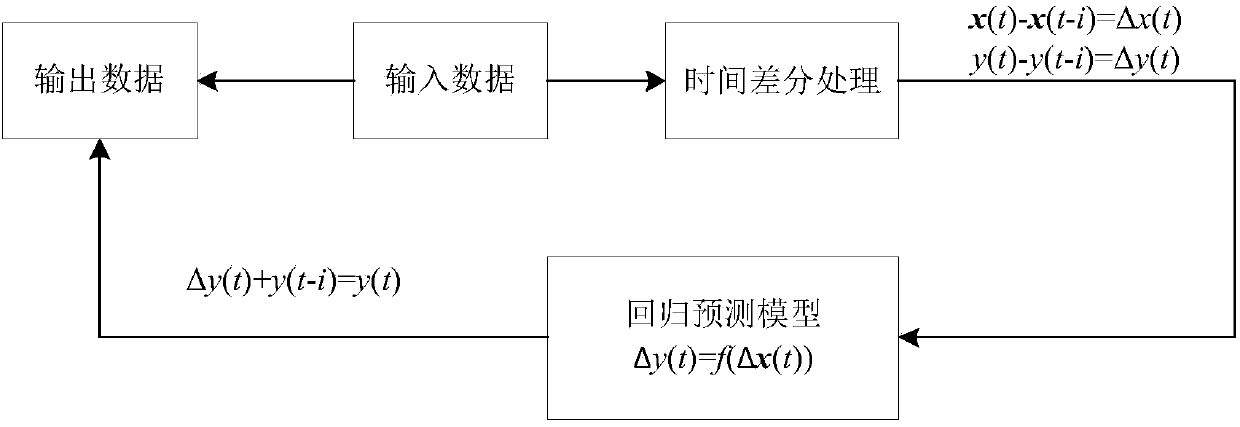

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

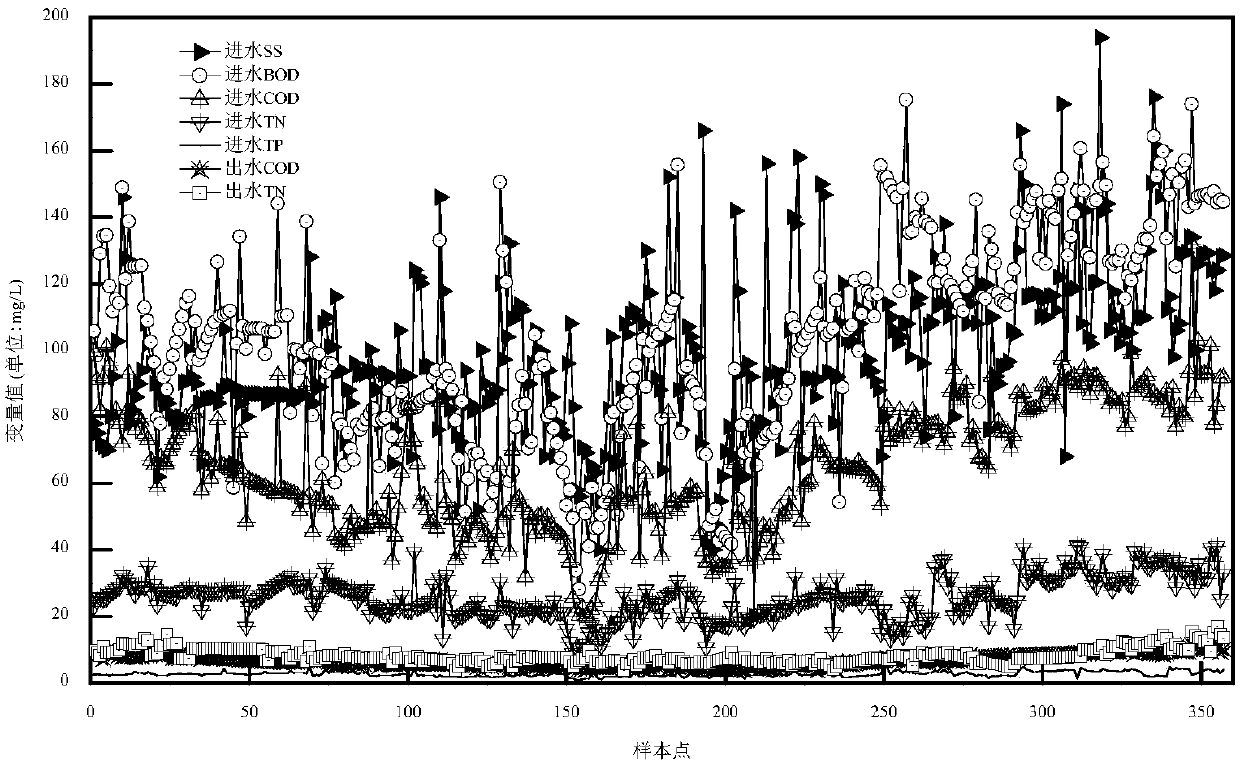

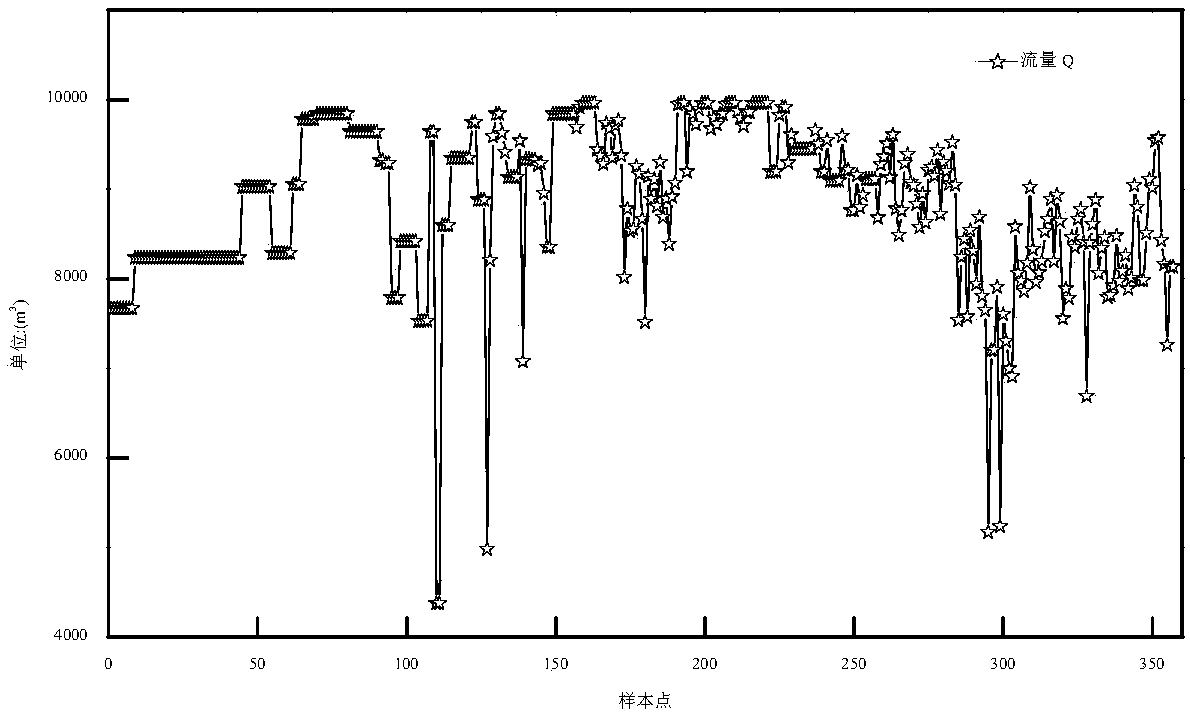

[0129] The sewage data is taken from the sewage test data of a sewage treatment plant. The data includes 8 variables and a total of 356 days of sample data, such as figure 2 , image 3 shown. figure 2 It is influent suspended solids (SS), influent biological oxygen demand (BOD), influent chemical oxygen demand, influent total nitrogen (TN), influent total phosphorus (TP), effluent COD and effluent TN; image 3 is the total flow of sewage influent (Q).

[0130] The above algorithm is simulated by MATLAB, and the present invention is further described in detail:

[0131] Step 1: Perform time difference processing on the collected 356-day measurement data. The latter 120 samples are used as the test set of the model to test the predictive ability of the model. The input variables of the model are total flow of sewage influent, suspended solids in influent, biological oxygen demand in influent, chemical oxygen demand in influent, total nitrogen and total phosphorus in influe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com