A calibration method system for torque measurement

A torque measurement and calibration system technology, applied in the field of drilling, can solve the problems of poor accuracy of engineering parameters, complex interaction process between drill string and wellbore, low accuracy and reliability of calculation results, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

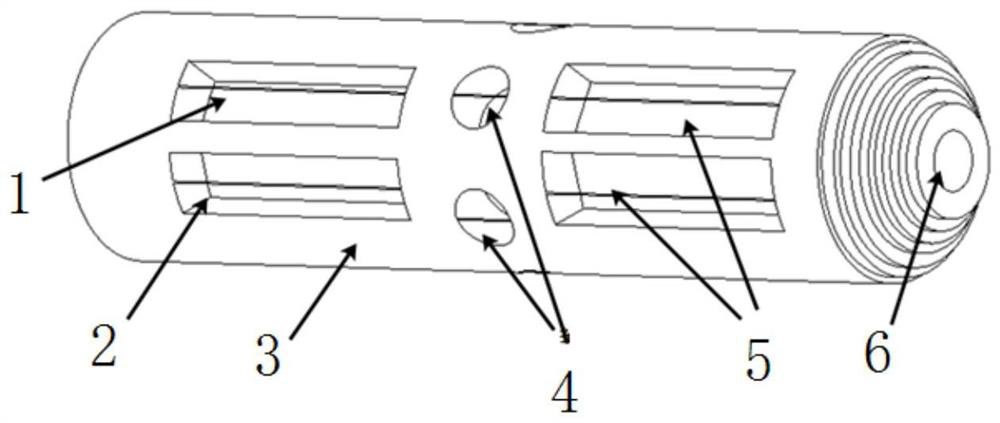

[0075] 1. Drill collar device structure

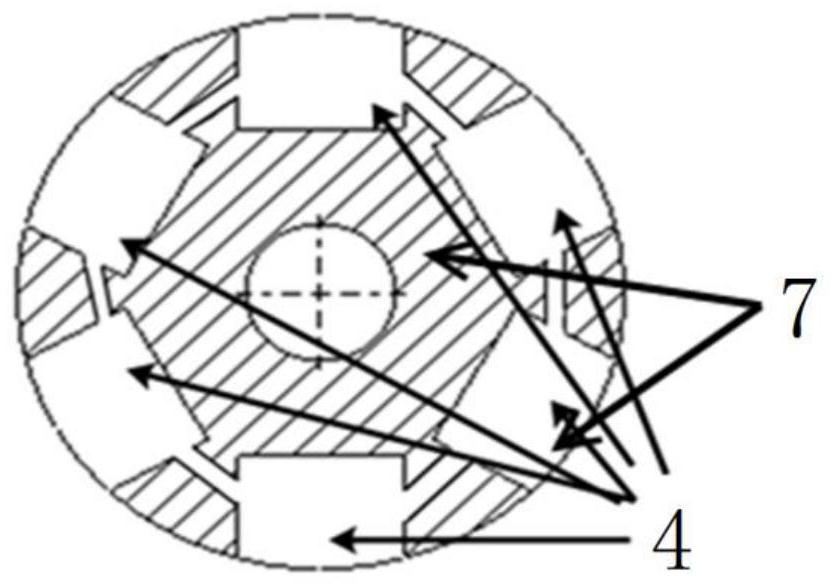

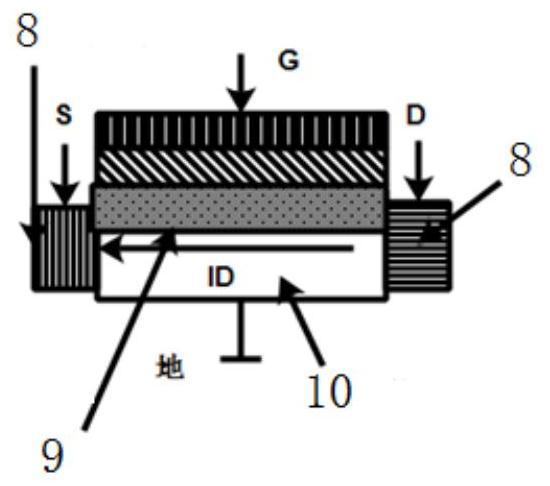

[0076] see Picture 1-1 , The downhole torque measurement device while drilling provided by the implementation of the present invention includes: a downhole torque measurement and measurement drill collar installation body capable of bearing oil drilling pressure, a round hole for installing a torque measurement sensor array, a battery compartment, a pressure measurement circuit compartment, and an MWD interface Protocol circuit cabin.

[0077] The torque measurement sensor is arranged in an equidistant circular array in the axial direction of the drill collar body. It is composed of a torque measurement ring embedded with a torque and strain measurement body. The ring array can measure the short circuit of dynamic parameters during coiled tubing drilling. The measured torque signal is sent to the measurement signal conditioning circuit for corresponding signal processing, and converted into a digital torque value through AD sampling, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com