Auto-cascade condensing unit

A condensing unit, self-cascading technology, applied in refrigerators, compressors, steam condensation, etc., can solve problems affecting system stability and safety, many explosion-proof electrical instruments, complex systems, etc., to improve equipment utilization, The effect of compact structure and simple system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

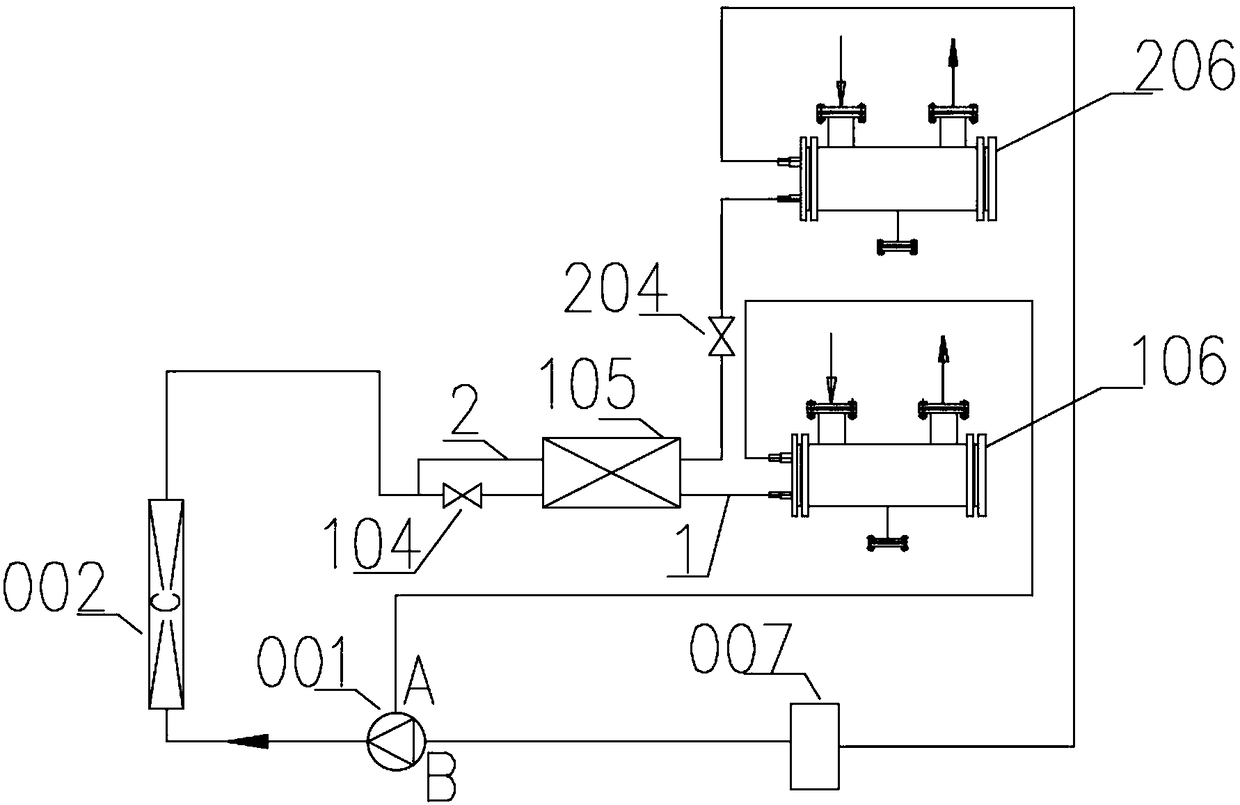

[0039] Such as figure 1 A self-cascading condensing unit shown includes:

[0040] Compressor 001, which is used to provide power and system pressure difference for refrigerant flow;

[0041] Condenser 002, which is connected to compressor 001, and is used to dissipate heat from the refrigerant flowing out of compressor 001;

[0042] A refrigerant classifying device, which is connected to the condenser 002, and is used to classify the refrigerant flowing out of the condenser 002 into various temperature levels;

[0043] The heat exchange terminal is respectively connected with the refrigerant classifying device and the compressor 001, and is used for exchanging heat with the outside using the refrigerant flowing out of the refrigerant classifying device;

[0044] The invention divides the temperature of the refrigerant into multiple different levels through the refrigerant grading device, and only needs one compressor 001 to form multiple temperature gradients at the end of t...

Embodiment 2

[0059] Such as figure 2 A self-cascading condensing unit shown includes:

[0060] Compressor 001, which is used to provide power for refrigerant flow;

[0061] Condenser 002, which is connected to compressor 001, and is used to dissipate heat from the refrigerant flowing out of compressor 001;

[0062] A refrigerant classifying device, which is connected to the condenser 002, and is used to classify the refrigerant flowing out of the condenser 002 into various temperature levels;

[0063] The heat exchange terminal is respectively connected with the refrigerant classifying device and the compressor 001, and is used for exchanging heat with the outside using the refrigerant flowing out of the refrigerant classifying device;

[0064] The invention divides the temperature of the refrigerant into multiple different levels through the refrigerant grading device, and only needs one compressor 001 to form multiple temperature gradients at the end of the heat exchange for condensat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com