Elliptical perforated fins for finned tube refrigeration heat exchangers suitable for frosting conditions

A technology of fin tube type and elliptical hole, which is applied in the field of fin structure to achieve the effect of enhancing heat transfer performance, enhancing disturbance and reducing volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Structure and advantage of the present invention are described in detail below in conjunction with accompanying drawing:

[0030] 1. The geometric structure of elliptical perforated fins for finned tube refrigeration heat exchangers:

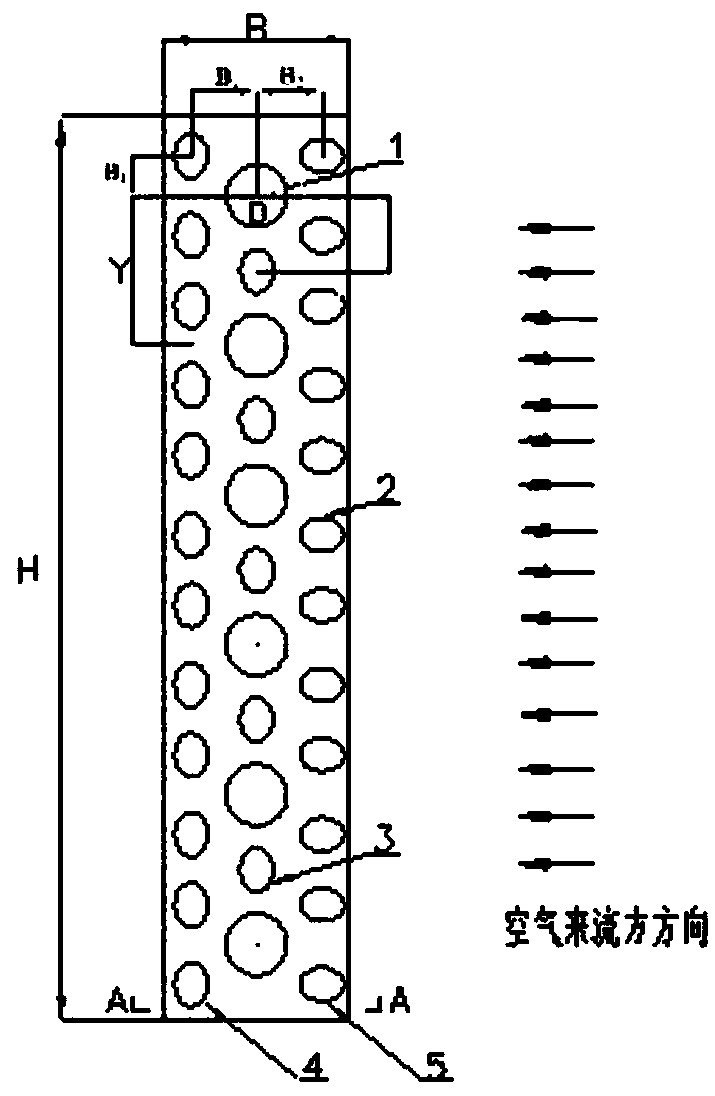

[0031] see figure 1 ,, figure 2 and image 3 In the middle of the fins 5, there is a row of cooling base tube holes 1, so that the elliptical perforated fins can be tightly connected to the cooling base tube with an outer diameter of D by using tube expansion technology. There are elliptical holes on the surface of the fins. Along the height direction of the fins, all the elliptical holes are arranged in three rows: the first row of elliptical holes 2 is on the side of the gas flow; the second row of elliptical holes 3 is arranged in the middle of the cooling base tube; the gas outflow The third row of oval holes 4 is arranged on the side. All oval holes have the same geometrical dimensions.

[0032] The long axes of the first row o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com