Single-cavity unsymmetrical sliding-vane-type vacuum pump

An asymmetrical, sliding-vane technology used in rotary piston pumps, pumps, rotary piston/swing piston pump components, etc., to solve problems such as exhaust leakage, short seal contact lines, and connectivity, and to improve Internal leakage and good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

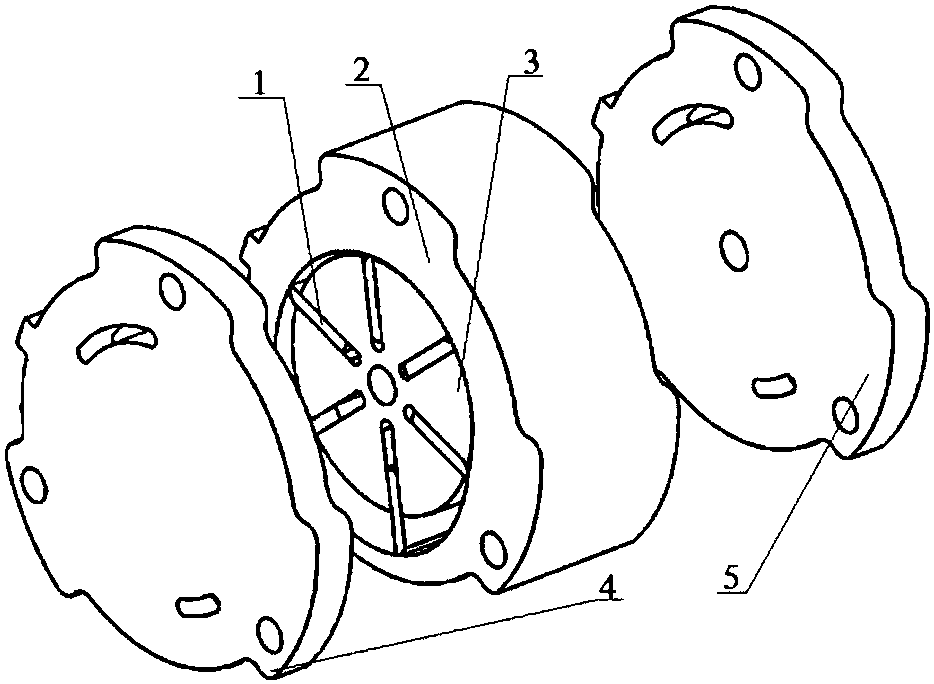

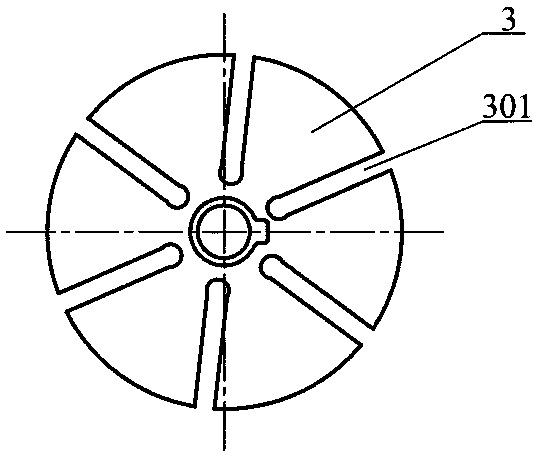

[0029] Such as figure 1 As shown, it is a schematic diagram of the assembly relationship of a single-cavity asymmetric sliding vane vacuum pump, and the components of the sliding vane (1), cylinder (2), rotor (3), upper end cover (4) and lower end cover (5) are assembled to obtain Schematic diagram of the assembly relationship.

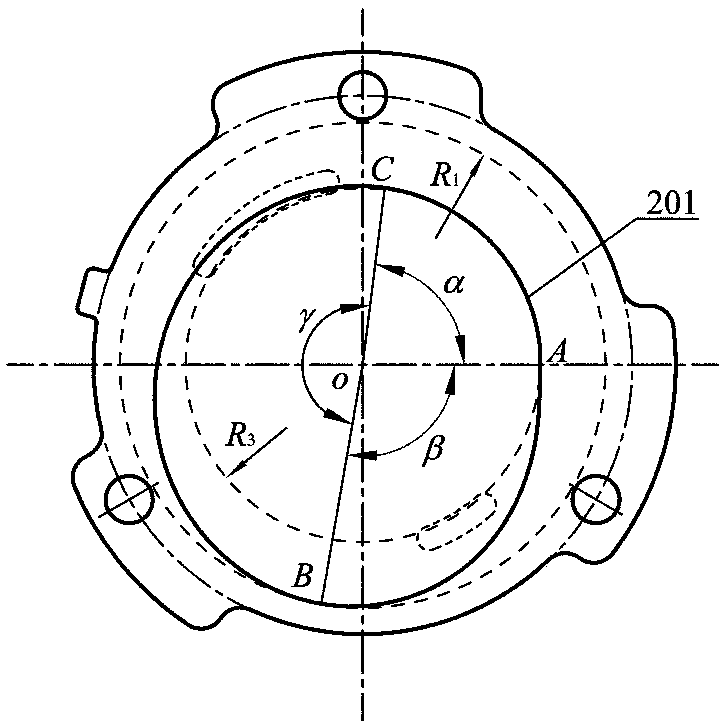

[0030] Such as figure 2 As shown, it is the main figure of the cylinder profile, the cylinder profile (201) on the cylinder (2) is an asymmetrical closed curve with continuous second-order derivatives, that is, the points of the cylinder profile (201) are continuous and smooth. There is a sudden change point, and there is no center line passing through its center of rotation O so that the cylinder profile (201) is symmetrical about its axis; the cylinder profile (201) is the coordinate origin with its center of rotation O, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com