Crack sealing assisting device for bridge construction

An auxiliary equipment, bridge construction technology, applied in bridge construction, bridges, erection/assembly of bridges, etc., can solve the problems of waste of resources, unsightly, easy to irrigate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

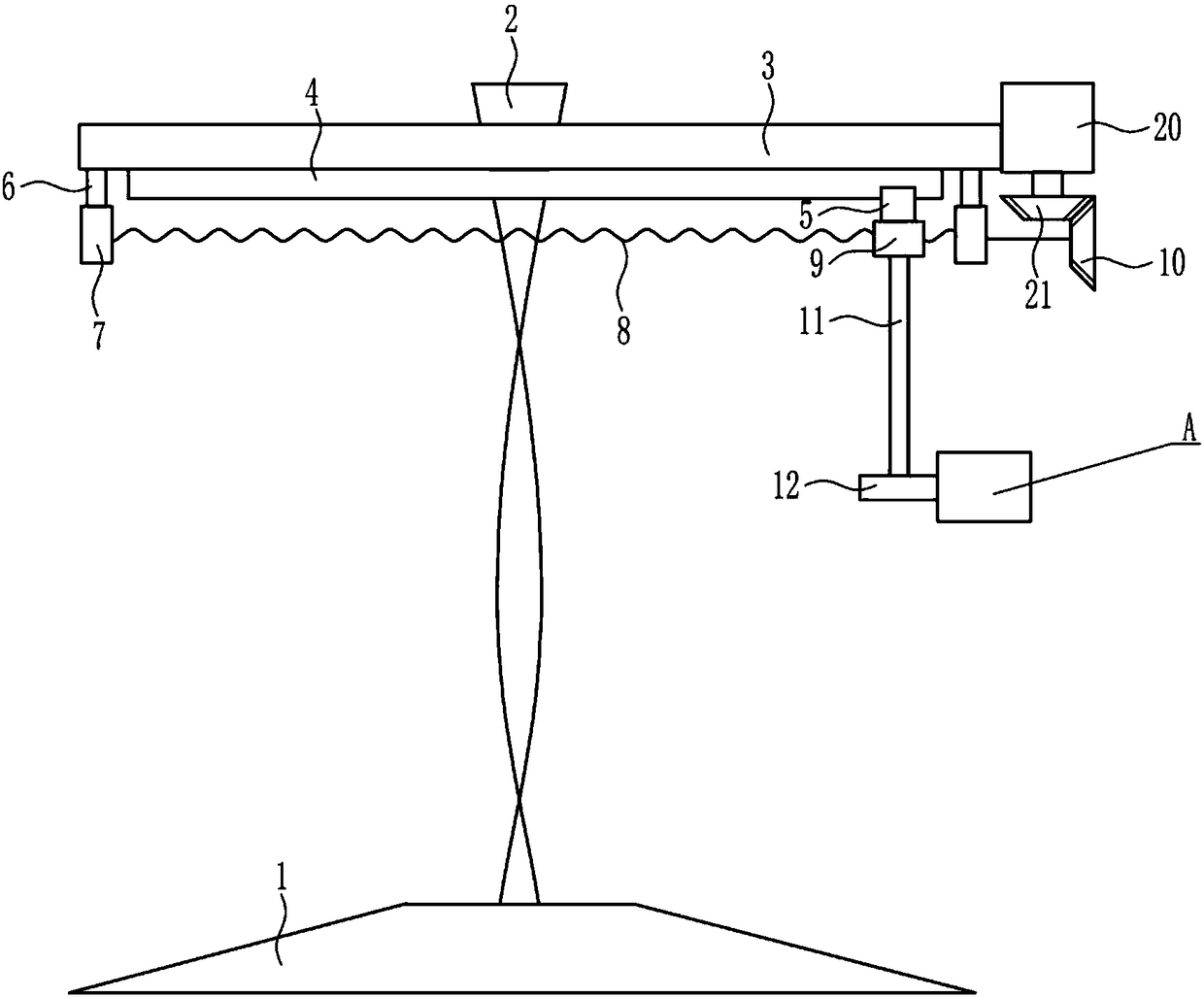

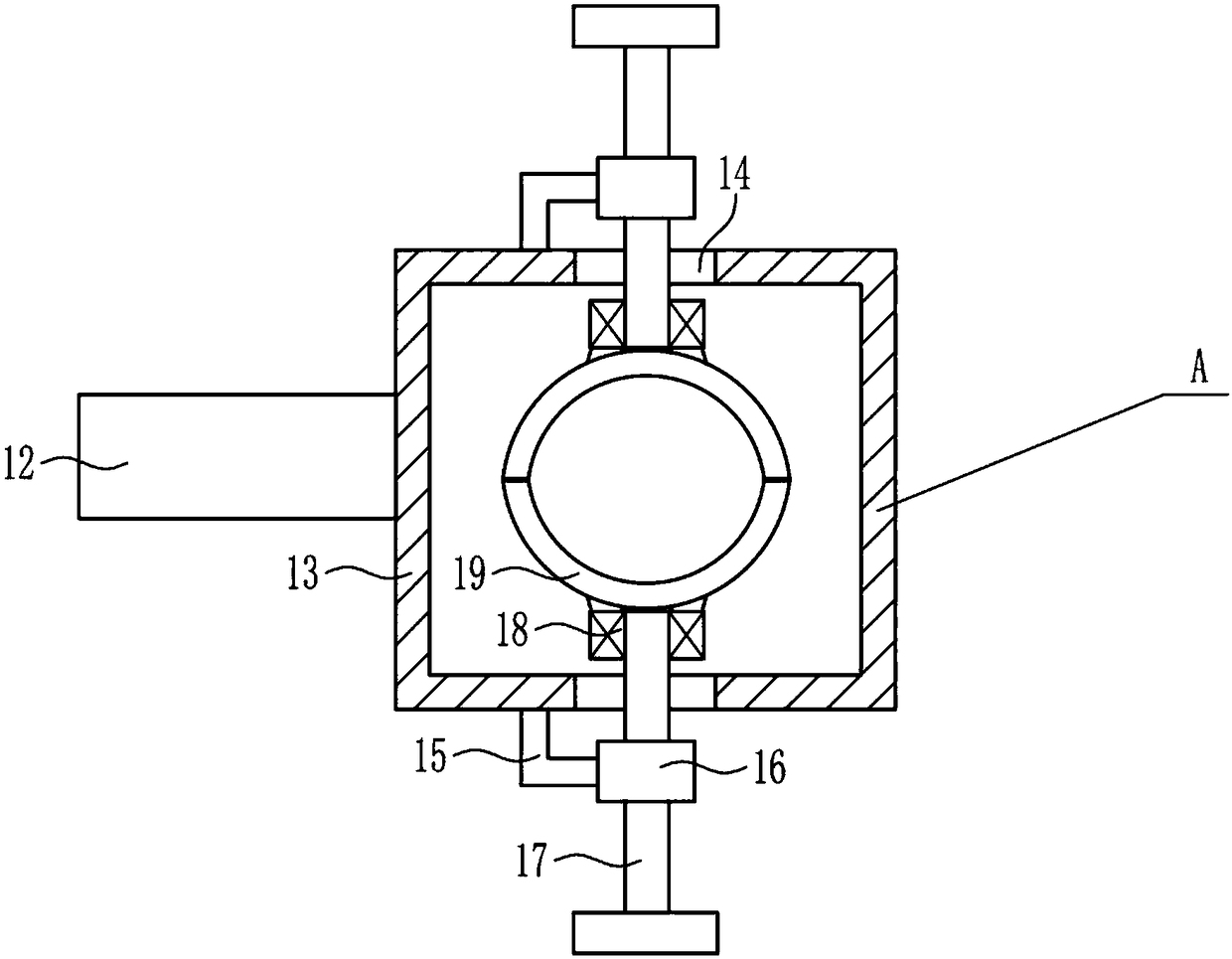

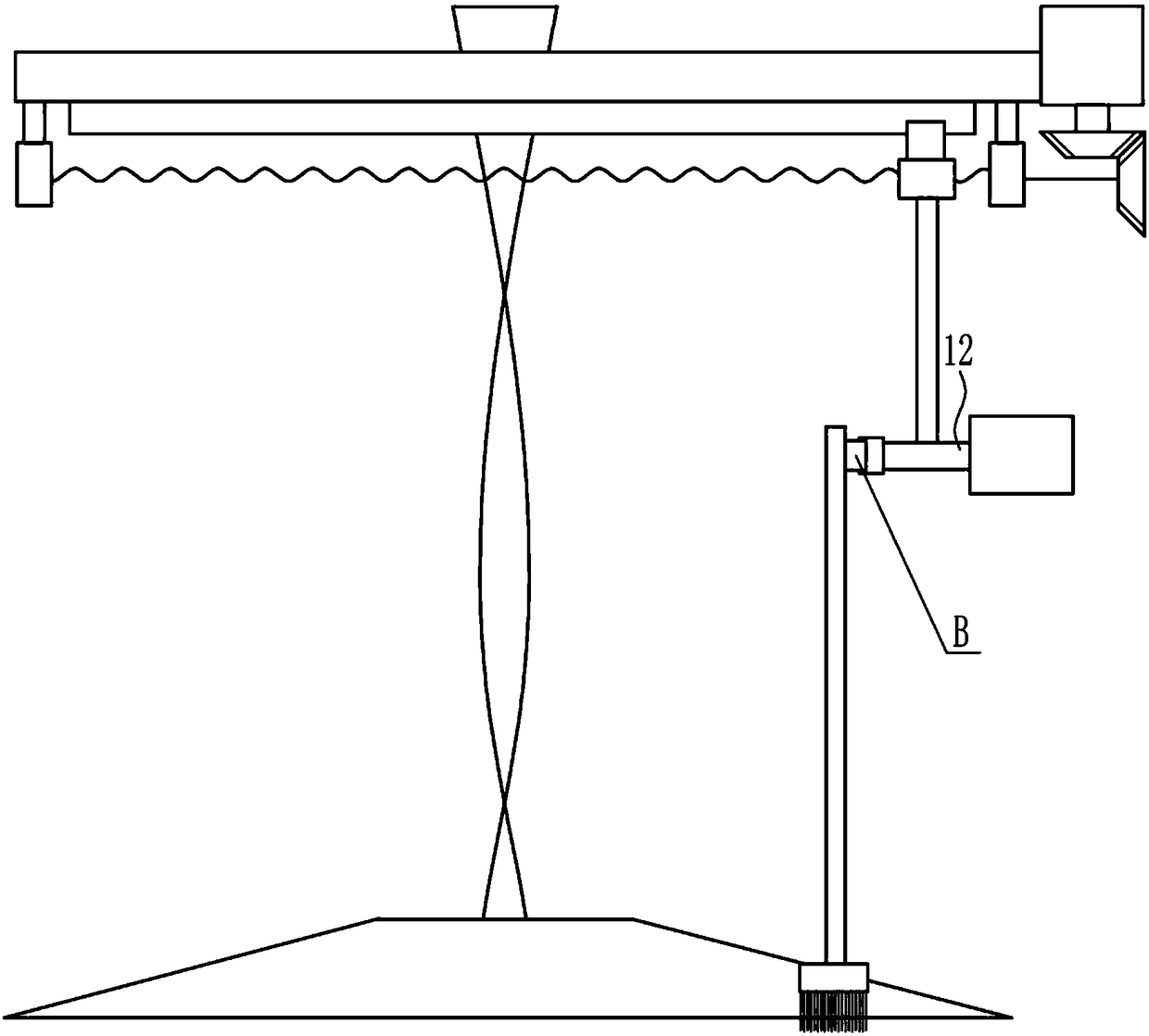

[0027] A kind of auxiliary equipment for filling joints in bridge construction, such as Figure 1-6 As shown, it includes a base 1, a support plate 2, a horizontal plate 3, a first slide rail 4, a first slider 5, a support plate 6, a first bearing seat 7, a screw rod 8, a screw nut 9, and a first bevel gear 10. Riser 11, connecting plate 12, box body 13, L-shaped plate 15, nut 16, T-shaped screw 17, second bearing seat 18, arc clamping block 19, motor 20 and second bevel gear 21, base 1 The top of the support plate 2 is connected with a support plate 2, the upper part of the front side of the support plate 2 is connected with a horizontal plate 3, the bottom of the horizontal plate 3 is connected with a first slide rail 4, and the first slide rail 4 is provided with a first slider 5, the first The bottom of the horizontal plate 3 on the left and right sides of the slide rail 4 is connected with a support plate 6, the bottom of the support plate 6 is equipped with a first beari...

Embodiment 2

[0029] A kind of auxiliary equipment for filling joints in bridge construction, such as Figure 1-6 As shown, it includes a base 1, a support plate 2, a horizontal plate 3, a first slide rail 4, a first slider 5, a support plate 6, a first bearing seat 7, a screw rod 8, a screw nut 9, and a first bevel gear 10. Riser 11, connecting plate 12, box body 13, L-shaped plate 15, nut 16, T-shaped screw 17, second bearing seat 18, arc clamping block 19, motor 20 and second bevel gear 21, base 1 The top of the support plate 2 is connected with a support plate 2, the upper part of the front side of the support plate 2 is connected with a horizontal plate 3, the bottom of the horizontal plate 3 is connected with a first slide rail 4, and the first slide rail 4 is provided with a first slider 5, the first The bottom of the horizontal plate 3 on the left and right sides of the slide rail 4 is connected with a support plate 6, the bottom of the support plate 6 is equipped with a first bearing...

Embodiment 3

[0032] A kind of auxiliary equipment for filling joints in bridge construction, such as Figure 1-6 As shown, it includes a base 1, a support plate 2, a horizontal plate 3, a first slide rail 4, a first slider 5, a support plate 6, a first bearing seat 7, a screw rod 8, a screw nut 9, and a first bevel gear 10. Riser 11, connecting plate 12, box body 13, L-shaped plate 15, nut 16, T-shaped screw 17, second bearing seat 18, arc clamping block 19, motor 20 and second bevel gear 21, base 1 The top of the support plate 2 is connected with a support plate 2, the upper part of the front side of the support plate 2 is connected with a horizontal plate 3, the bottom of the horizontal plate 3 is connected with a first slide rail 4, and the first slide rail 4 is provided with a first slider 5, the first The bottom of the horizontal plate 3 on the left and right sides of the slide rail 4 is connected with a support plate 6, the bottom of the support plate 6 is equipped with a first beari...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com