Multi-layer optical recording device

A technology of optical recording and differential optics, which is applied to optical recording media, optical recording/reproduction, magnetic recording, etc., and can solve the problems of complex reproducing devices and single laser diodes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

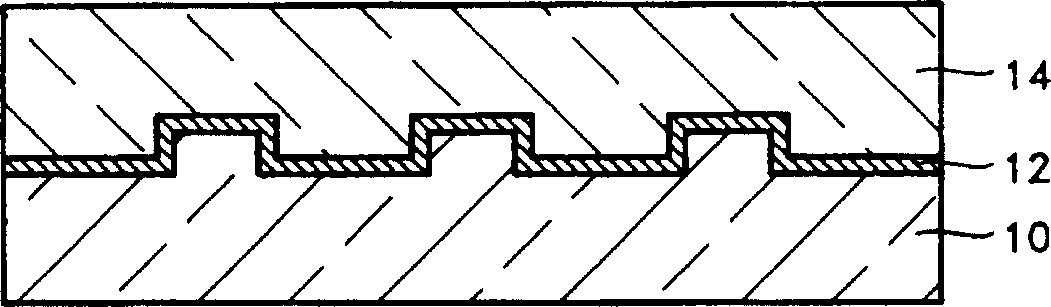

Image

Examples

Embodiment Construction

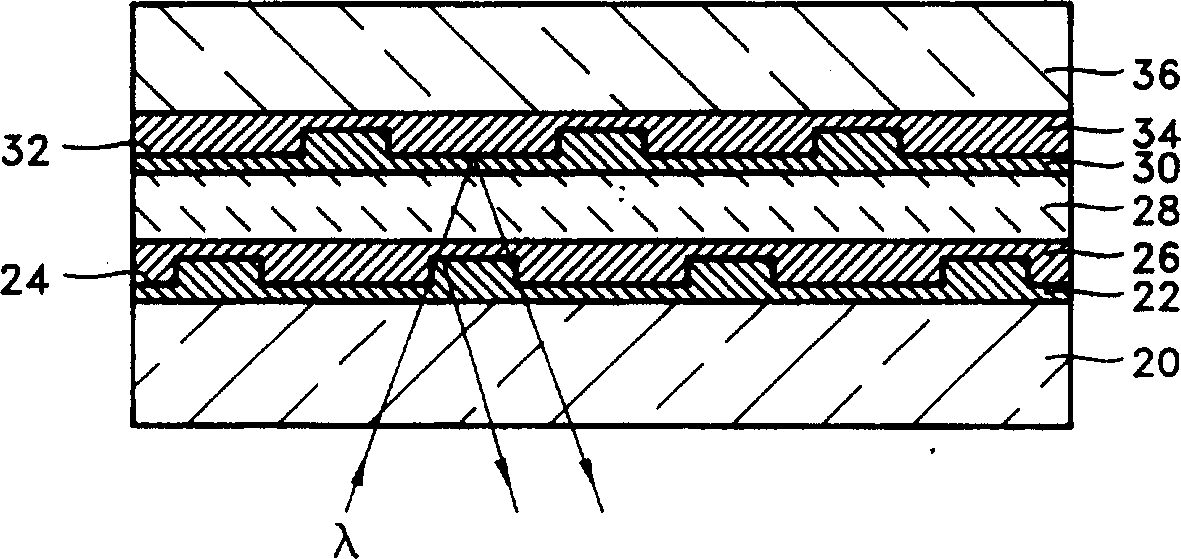

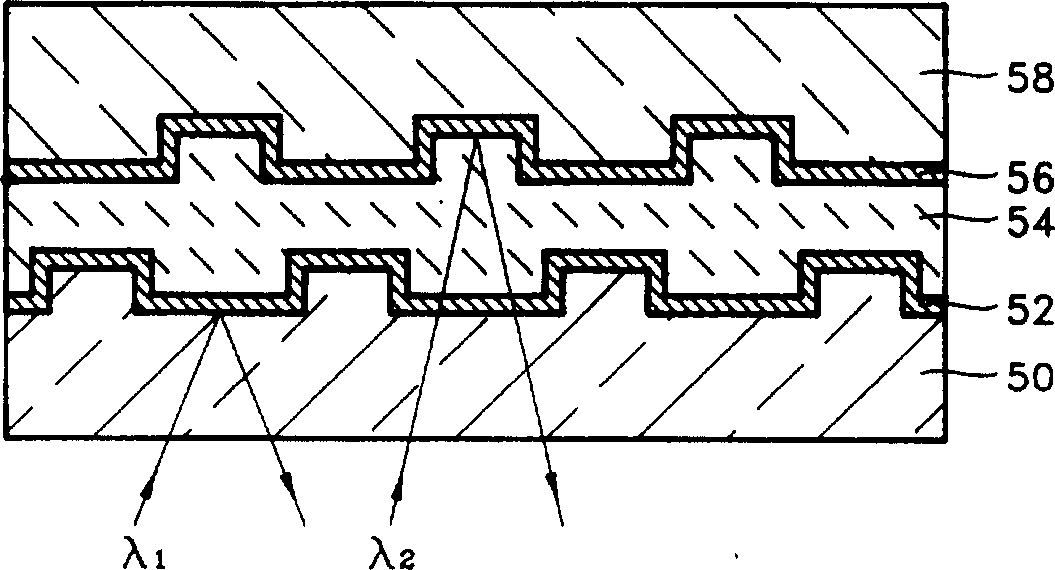

[0023] Figure 4 is a schematic diagram of a multilayer optical recording device according to an embodiment of the present invention.

[0024] Optical disc structure according to the present invention comprises: a transparent substrate 100 that is made by the transparent resin such as PC material by conventional method, a first reflective film 102 that forms on this transparent substrate, a first reflective film of adhering 102 to the adhesion layer 104 of the second reflection film 106, the second reflection film 106 adhered to the first reflection film through the adhesion layer 104, and a protective film 108 formed on the second reflection film 106. The first reflective film 102 adjacent to the transparent substrate 100 is composed of two layers, both of which are preferably composed of dielectric materials. The first dielectric layer a and the second dielectric layer b near the transparent substrate 100 have different refractive indices, and the refractive index of the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com