Leather making industrial salt recycling method and salt recycling system

An industrial salt and ultrafiltration system technology, applied in the field of tanning wastewater reuse, can solve problems such as difficulty in meeting clean production and environmental protection discharge requirements, unfavorable biochemical treatment of wastewater, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

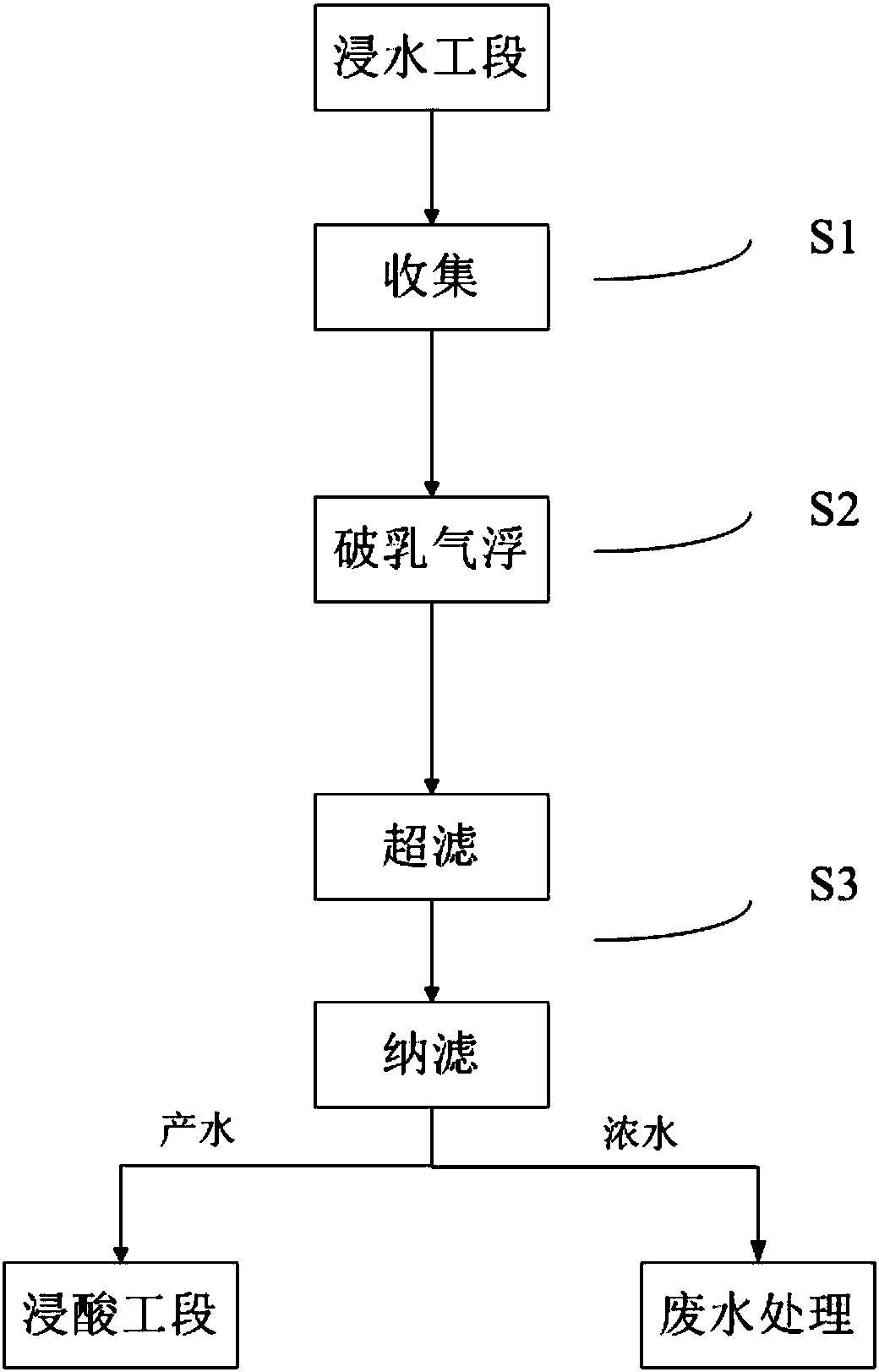

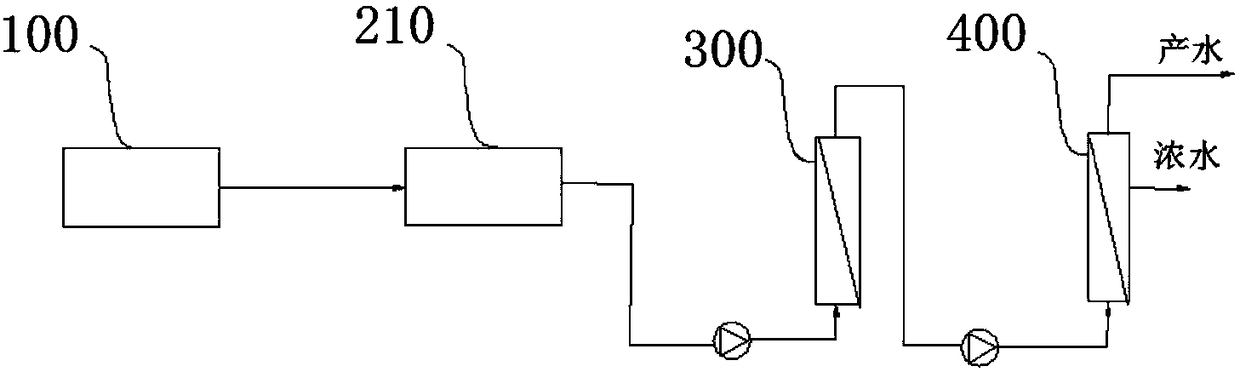

[0091] A salt recycling system for tanning industry, comprising sequentially connected wastewater collection tanks, demulsification-air flotation treatment system, ultrafiltration system and nanofiltration system.

[0092] The salt recycling method of the leather industry salt recycling system comprises the following steps:

[0093] The saline wastewater from the soaking section of tanning production is first collected into the wastewater collection tank, and then enters the demulsification-air flotation treatment system, ultrafiltration system and nanofiltration system in turn, and the effluent water obtained from the nanofiltration system enters the pickling section of tanning production , concentrated water enters the next step of processing equipment.

[0094] The salt content of the saline waste water in the waste water collection pond is 6% (wt%), the salt content of the treated water is 4.2% (wt%), and the salt content of concentrated water is 1.8% (wt%).

Embodiment 2

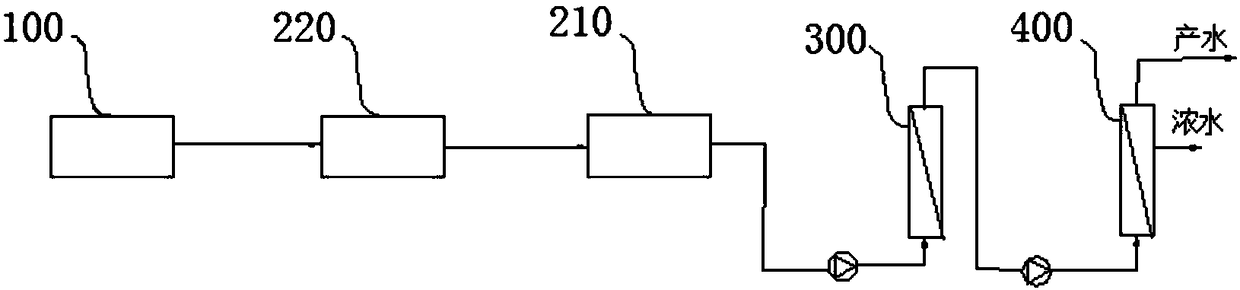

[0096] A salt recycling system for tanning industry, comprising a waste water collection tank, a grid tank, a demulsification-air flotation treatment system, an ultrafiltration system and a nanofiltration system connected in sequence.

[0097] The salt recycling method of the leather industry salt recycling system comprises the following steps:

[0098] The saline wastewater in the immersion section of tanning production is first collected into the wastewater collection tank, and then enters the grill tank, demulsification-air flotation treatment system, ultrafiltration system and nanofiltration system in sequence. The effluent water obtained from the nanofiltration system enters the tannery In the pickling section of production, the concentrated water enters the next processing equipment.

[0099] The salt content of the saline waste water in the waste water collection pond is 6% (wt%), the salt content of the treated water is 4.5% (wt%), and the salt content in the concentra...

Embodiment 3

[0101] A salt recycling system for tanning industry, comprising a waste water collection pond, a waste water regulating pond, a demulsification-air flotation treatment system, an ultrafiltration system and a nanofiltration system connected in sequence.

[0102] The salt recycling method of the leather industry salt recycling system comprises the following steps:

[0103] The saline wastewater in the immersion section of tanning production is first collected into the wastewater collection tank, and then enters the wastewater adjustment tank, demulsification-air flotation treatment system, ultrafiltration system and nanofiltration system in turn. The effluent water obtained from the nanofiltration system enters the tannery In the pickling section of production, the concentrated water enters the next processing equipment.

[0104] The salt content of the saline waste water in the waste water collection pond is 6.5% (wt%), the salt content of the treated water is 4.55% (wt%), and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com