Fenton catalytic oxidation reactor and high-difficulty treatment method for industrial wastewater

A technology for catalytic oxidation and industrial wastewater, which is applied in the direction of oxidized water/sewage treatment, chemical instruments and methods, and water treatment of special compounds. Fast, less drug consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

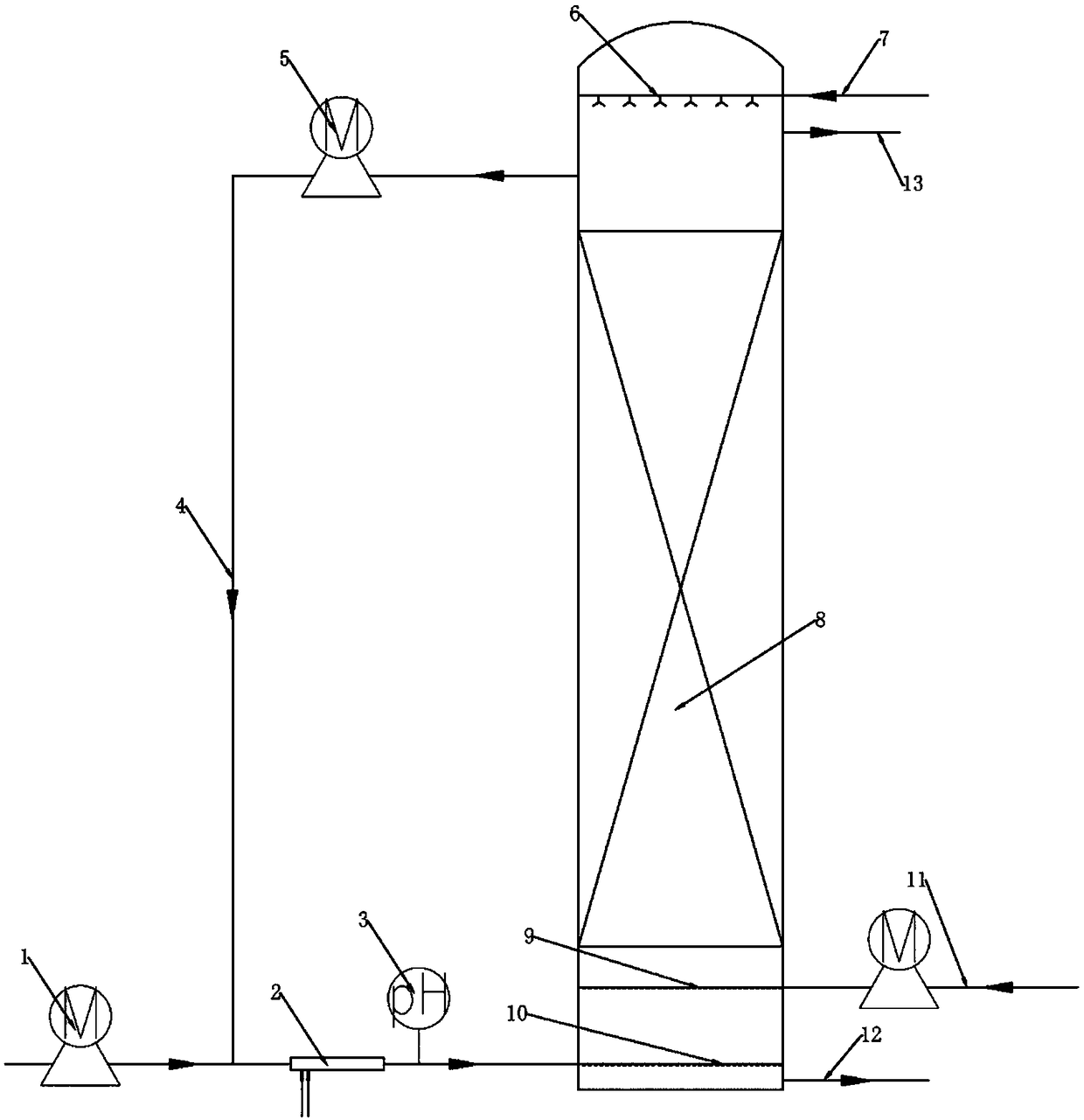

[0027] Such as figure 1 As shown, a Fenton catalytic oxidation reactor includes a reactor body, and the interior of the reactor body is sequentially provided with a water inlet distribution pipe 10, an oxidant dosing pipe 9, a solid-phase catalyst layer 8 and a spray nozzle. Showering device 6, described inlet water distribution pipe 10 is sequentially connected to online pH meter 3, pipeline mixer 2 and water inlet lifting pump 1 through waste water inlet pipe, and described pipeline mixer 2 is provided with sulfuric acid drug inlet and sulfuric acid Iron salt drug inlet, the oxidant dosing pipe 9 is connected to the oxidant dosing pump 11, the spray device 6 is connected to the flushing water inlet pipeline 7, the solid phase catalyst layer 8 is connected to the spray device 6 The reactor main body in between is provided with a reactor outlet pipe 13 and a return pipe 4 from top to bottom, and the return pipe communicates with the waste water inlet pipe through a return pump...

Embodiment 2

[0033] A treatment method for highly difficult industrial waste water, comprising the following steps:

[0034] (1) The difficult industrial wastewater enters the water inlet distribution pipe 10 at the bottom of the reactor main body through the wastewater inlet pipe under the action of the water inlet lift pump 1, and sulfuric acid and ferrous sulfate enter the pipeline mixer 2 to mix with the difficult industrial wastewater, And through the water distribution hole on the water distribution pipe 10, it flows upward in the reactor, and the pH of the wastewater inlet is monitored by the online pH meter 3. The pH of the wastewater is between 2.5-4, and the temperature is set at 20-35 ° C;

[0035] (2) The oxidant is pumped into the oxidant dosing pipe 9 through the oxidant dosing pump, the oxidant flows out from the orifice of the oxidant dosing pipe 9, and mixes with the upwardly flowing waste water. After the oxidant and waste water are mixed, they flow upward under the action...

Embodiment example 1

[0041]In the advanced treatment of antibiotic wastewater, the Fenton catalytic oxidation reactor is used, and the residence time of sewage is 4h. Control the pH of the influent water at 2.5-3.0, the temperature at 28°C, and the molar ratio of the dosage of oxidant to the dosage of ferrous sulfate is 1:2.5. The aspect ratio of the reactor is 4. The height of the solid catalyst layer 8 is 2.5 times the diameter.

[0042] The solid-phase catalyst uses granular ceramics with a diameter of 10mm as the carrier.

[0043] After adopting this reactor, the concentration of CODcr in wastewater is reduced from 320mg / L to below 115mg / L.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com