A kind of sulfonic acid functionalized graphene dispersion system and preparation method thereof

A technology of dispersion system and sulfonic acid group, which is applied in the field of sulfonic acid group functionalized graphene dispersion system and its preparation, can solve problems such as easy agglomeration, achieve good stability and solve the effect of agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

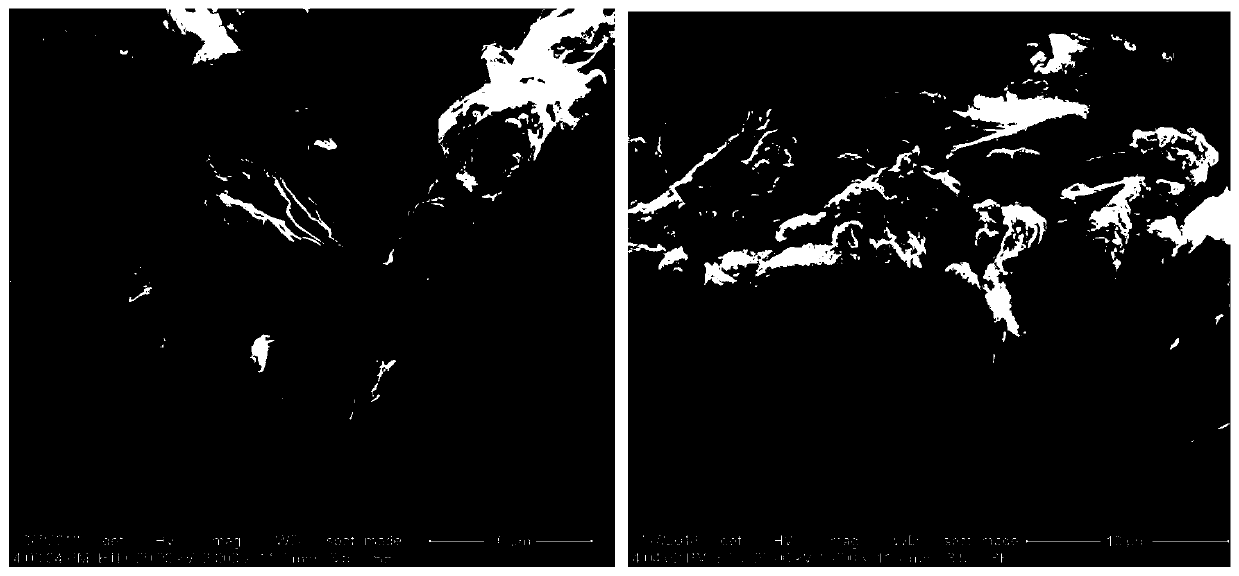

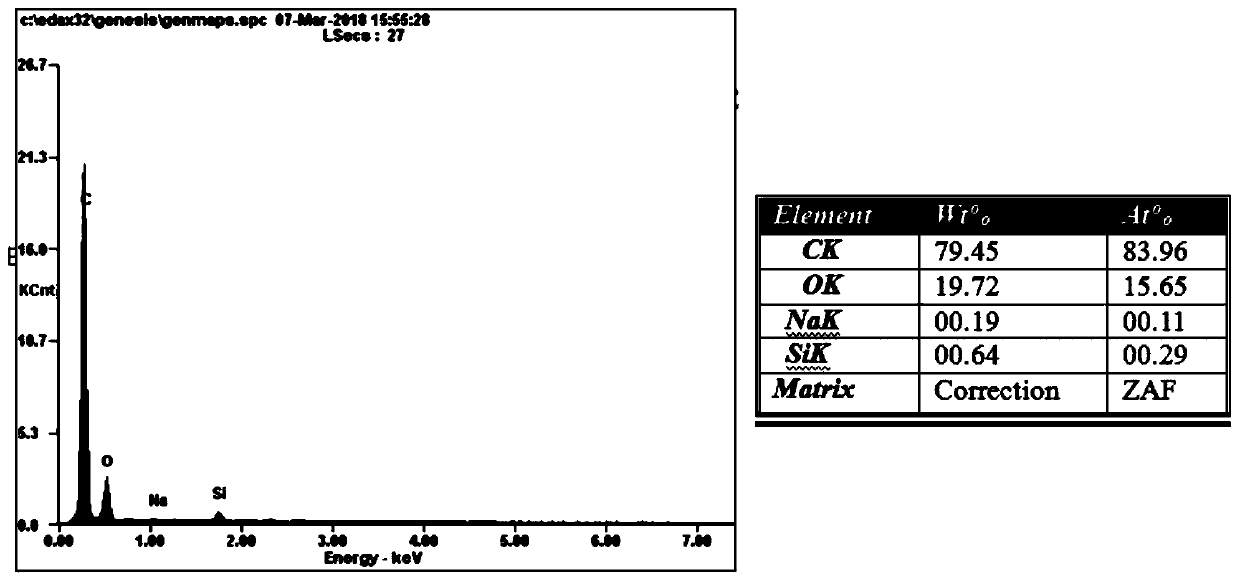

Image

Examples

preparation example Construction

[0031] In another typical embodiment of the present application, a method for preparing a sulfonic acid group functionalized graphene dispersion system is provided, comprising the following steps:

[0032] S1: disperse the sulfonic acid group functionalized graphene in an organic solvent to obtain a sulfonic acid group functionalized graphene dispersion;

[0033] S2: adding nanocellulose into the sulfonic acid functionalized graphene dispersion obtained in step S1, stirring in a water bath and ultrasonically dispersing to obtain a sulfonic acid functionalized graphene dispersion system.

[0034] The preparation method is simple to operate, and a stable sulfonic acid functionalized graphene dispersion system can be obtained only through simple steps of mixing, stirring in a water bath and ultrasonic dispersion.

[0035]In order to further improve the stability of the obtained sulfonic acid functionalized graphene dispersion system, before adding the nanocellulose into the sulfo...

Embodiment 1

[0048] A kind of preparation method of sulfonic acid functionalized graphene dispersion system, comprises the following steps:

[0049] (1) Add the sulfonic acid group functionalized graphene powder into N-methylpyrrolidone, mechanically stir for 20min and then ultrasonically vibrate for 2h to obtain a sulfonic acid group functionalized graphene-N-methylpyrrolidone dispersion, wherein The massfraction of sulfonic acid functionalized graphene is 10%;

[0050] (2) Dissolve 1g of nanocellulose particles in 90g of water, stir in a water bath at a constant temperature of 45°C for 12h until completely dissolved, then add 2mL of KH560 silane coupling agent to modify the surface of nanocellulose, and then ultrasonically disperse for 2h to obtain a mass fraction of 1% modified nanocellulose aqueous solution, and then filtered, washed, and dried to obtain modified nanocellulose;

[0051] (3) Slowly add the modified nanocellulose into the sulfonic acid group functionalized graphene-N-me...

Embodiment 2

[0054] A kind of preparation method of sulfonic acid functionalized graphene dispersion system, comprises the following steps:

[0055] (1) Add the sulfonic acid group functionalized graphene powder into acetone, and then carry out ultrasonic dispersion for 2h to obtain a sulfonic acid group functionalized graphene-acetone solution, wherein the mass fraction of the sulfonic acid group functionalized graphene is 10% ;

[0056] (2) Dissolve 2g of nanocellulose particles in 98g of water, stir in a water bath at a constant temperature of 45°C for 12h until completely dissolved, then add 2mL of KH1770 silane coupling agent to modify the surface of nanocellulose, and then ultrasonically disperse for 2h to obtain the mass fraction 2% modified nanocellulose aqueous solution, and then filtered, washed and dried to obtain modified nanocellulose;

[0057] (3) Slowly add the modified nanocellulose into the sulfonic acid group functionalized graphene-acetone solution, control the addition...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com