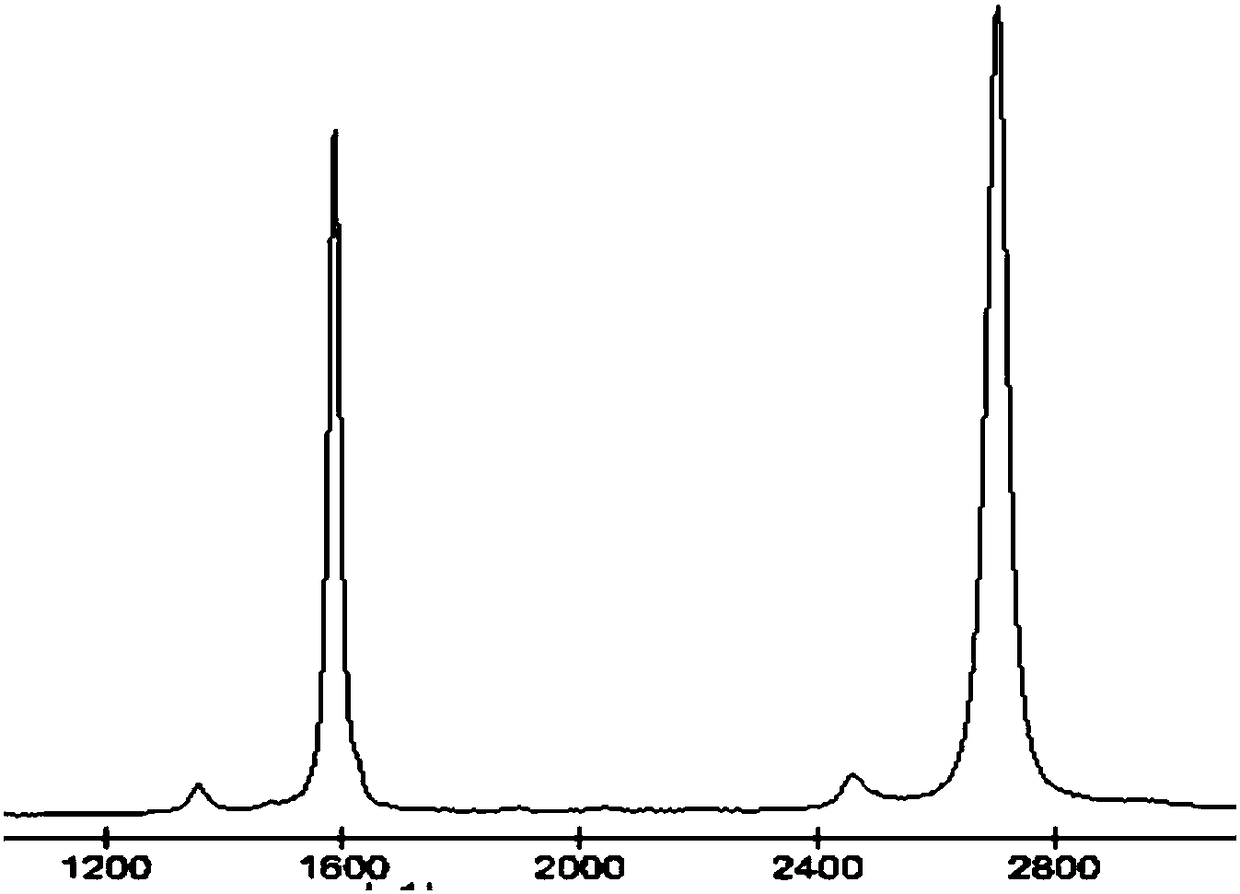

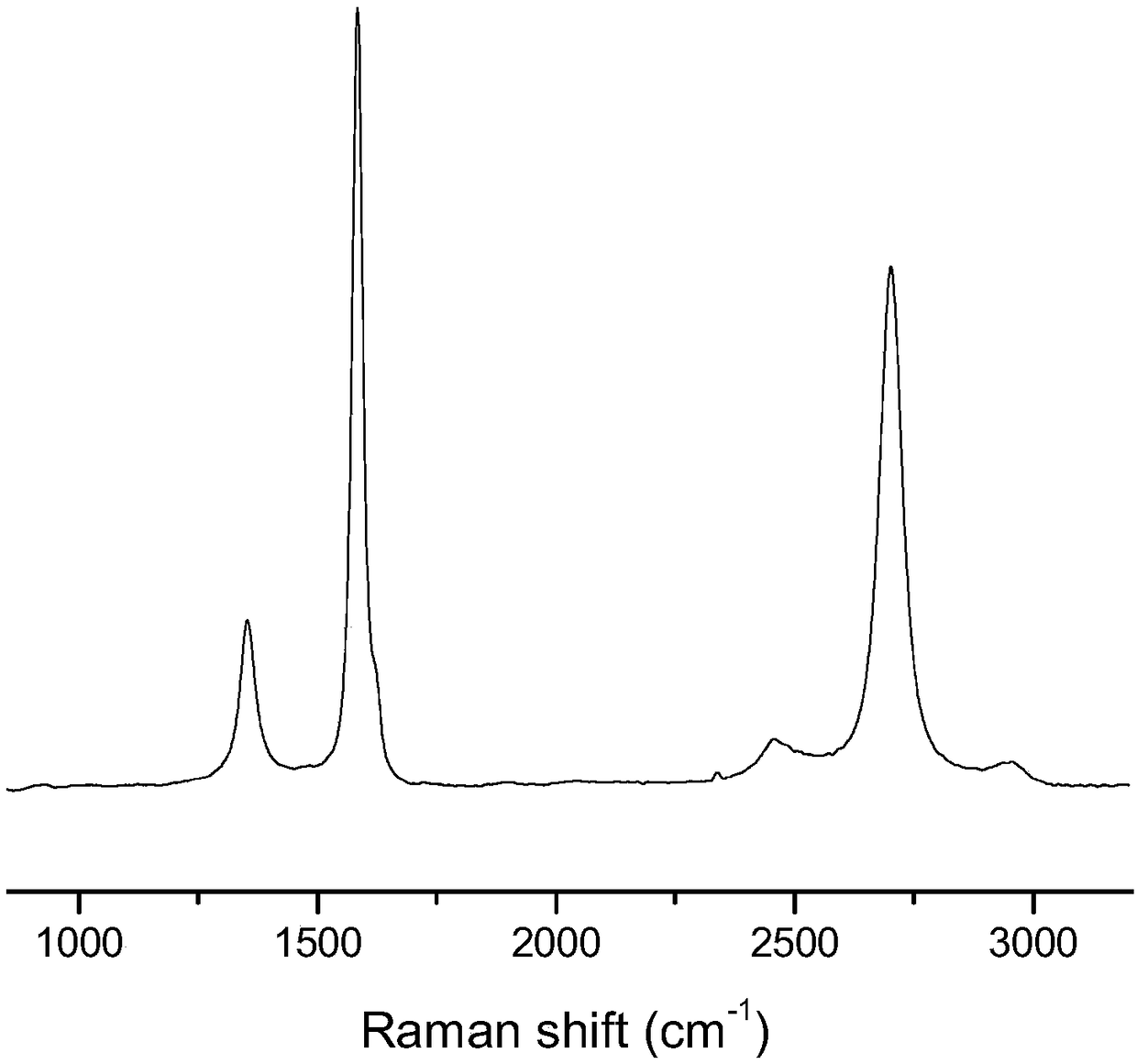

Graphene-based dye-sensitized transparent solar cell

A technology for solar cells and dye sensitization, applied in the field of solar electrodes, can solve the problems of low electron mobility, heavy metal pollution of ITO, unfavorable photoelectron transmission, etc., achieve high electrical conductivity and mechanical bearing performance, improve light conversion efficiency, and increase strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Graphene oxide was prepared into a graphene oxide aqueous solution with a concentration of 0.5ug / mL, and a hydrophilic polytetrafluoroethylene membrane was used as a substrate to form a membrane by suction filtration.

[0030] (2) Put the graphene oxide film attached to the hydrophilic polytetrafluoroethylene film in a closed container, and fumigate from the bottom to the top for 1 hour at a high temperature of 80 degrees HI.

[0031] (3) The melted solid transfer agent camphor is uniformly coated on the surface of the reduced graphene oxide film by evaporation, casting, etc., and slowly cooled at room temperature, and the film and the substrate are separated.

[0032] (4) Slowly volatilize the solid transfer agent from the graphene film supported by the solid transfer agent obtained above at 40 degrees to obtain an independent self-supporting graphene film.

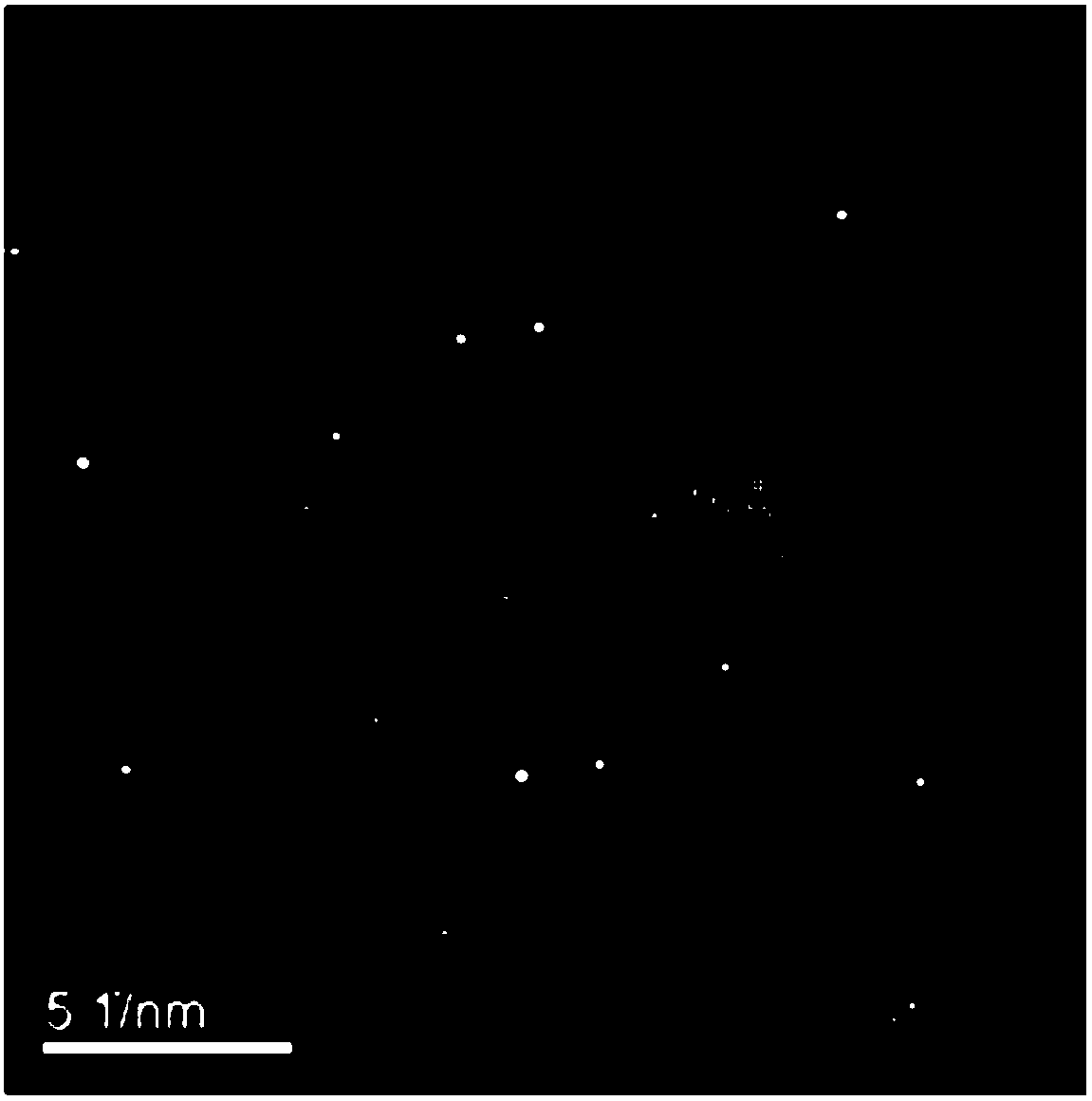

[0033] (5) Spraying a layer of metal titanium on the surface of the chemically reduced graphene film by mea...

Embodiment 2

[0039] (1) Graphene oxide was prepared into a graphene oxide aqueous solution with a concentration of 10ug / mL, and the PC film was used as the substrate to form a film by suction filtration.

[0040] (2) Put the graphene oxide film attached to the AAO film in a closed container, and fumigate from the bottom to the top at 100 degrees HI for 0.1 h.

[0041] (3) Uniformly coat the melted solid transfer agent naphthalene on the surface of the reduced graphene oxide film by evaporation, casting, etc., and slowly cool it at room temperature.

[0042] (4) Slowly volatilize the graphene film supported by the solid transfer agent obtained above at 80 to obtain an independent self-supporting graphene film.

[0043] (5) Spraying a layer of metal titanium on the surface of the chemically reduced graphene film by means of magnetron sputtering. By controlling the sputtering parameters, the molar weight of the finally sputtered metal nanoparticles is 18.4% of the molar weight of carbon atom...

Embodiment 3

[0049] (1) Graphene oxide was formulated into a graphene oxide aqueous solution with a concentration of 1 ug / mL, and a hydrophilic polytetrafluoroethylene membrane was used as a substrate to form a film by suction filtration.

[0050] (2) Put the graphene oxide film attached to the hydrophilic polytetrafluoroethylene in a closed container, and fumigate at a high temperature of 90 degrees HI from the bottom up for 0.5h.

[0051] (3) Uniformly coat the melted solid transfer agent sulfur on the surface of the reduced graphene oxide film by evaporation, casting, etc., and slowly cool it at room temperature.

[0052] (4) Slowly volatilize the graphene film supported by the solid transfer agent obtained above at 120 degrees to obtain an independent self-supporting graphene film.

[0053] (5) Spray one layer of metal cobalt on the graphene film surface of chemical reduction with the mode of magnetron sputtering, by controlling the sputtering parameter, the molar weight of the metal n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com