Large-scale programmable active transfer printing stamp and transfer printing method based on bionics design

A large-scale, stamping technology, which is applied in the field of large-scale programmable active transfer stamps and transfer printing, can solve the problems of local magnetic field resolution limitations, achieve simplified stamp structure and preparation costs, improve micro-high cavity integration, Ease of access

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The content of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

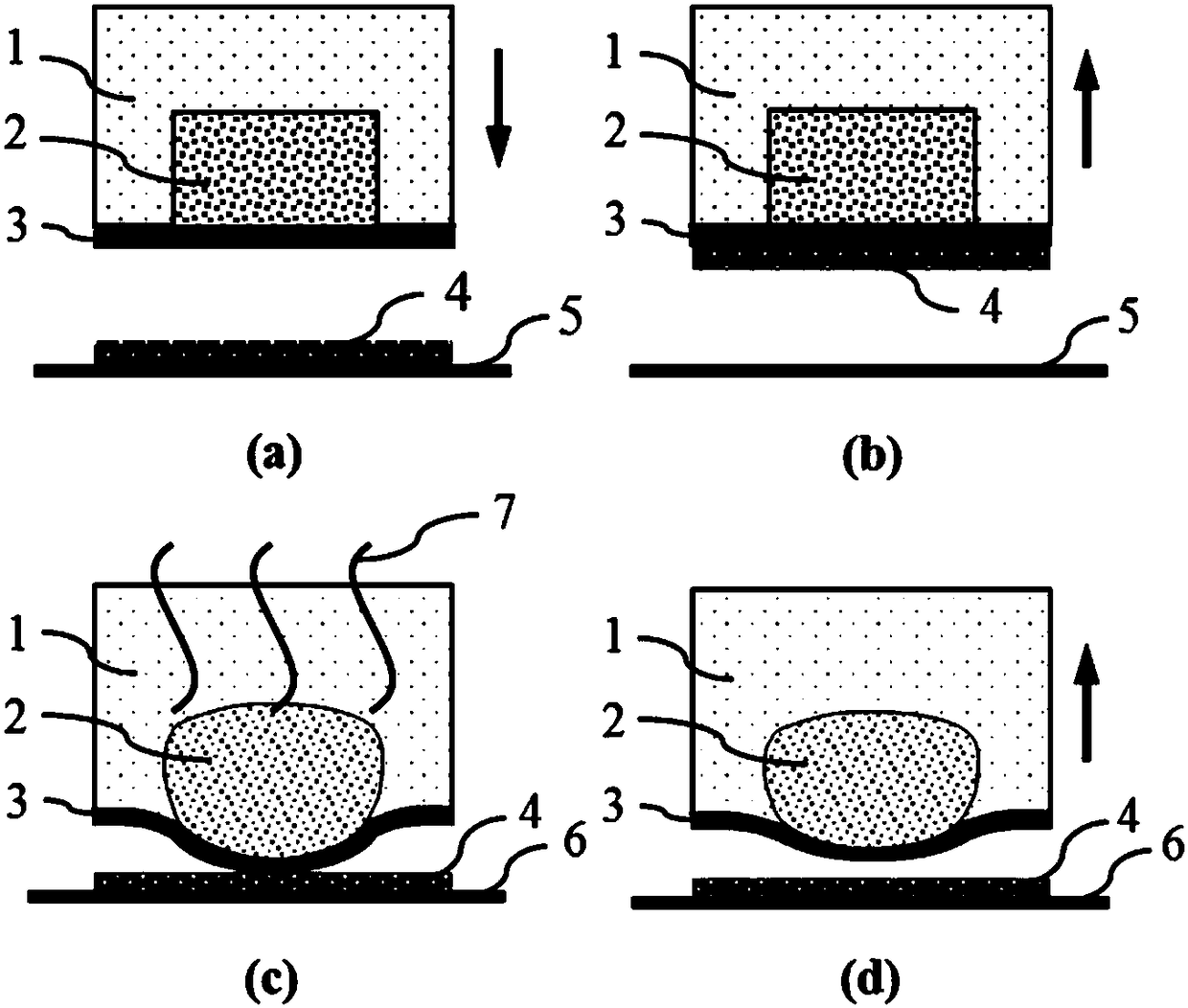

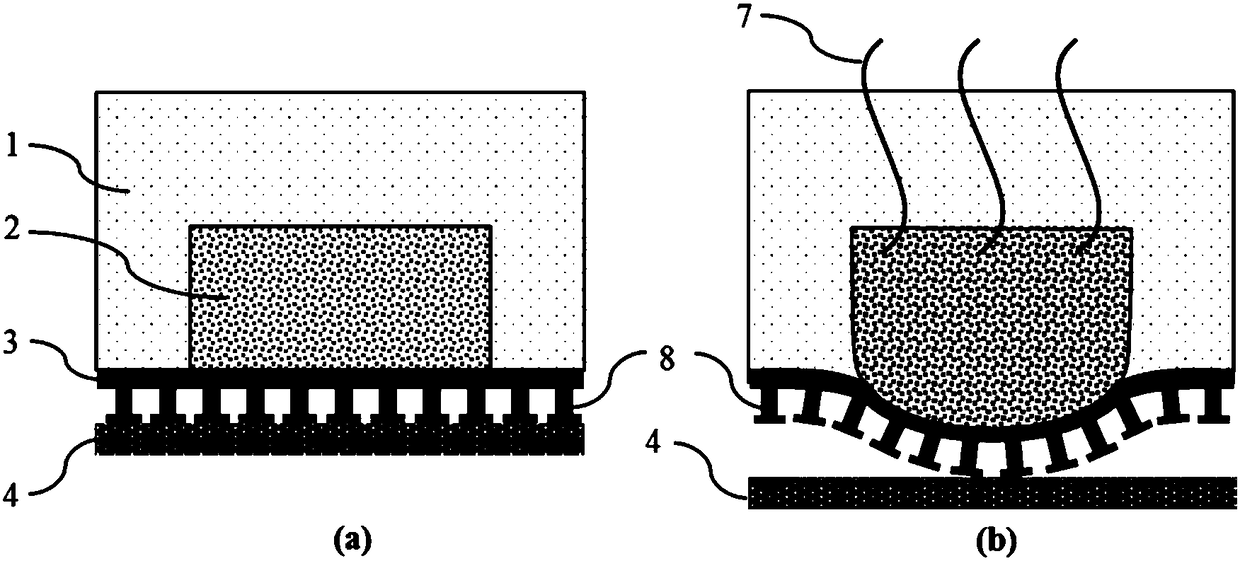

[0042] As an example, but not to limit the scope of the invention, figure 1 a is a schematic diagram of the structure of the aphid biomimetic seal. In nature, aphids control the strength of adhesion by controlling the contact area with the surface. The main body of the aphid bionic stamp (1) is made of low-modulus polymer, and a cavity array is made on the stamp body. After filling the cavity with a thermally driven working medium (2), it is packaged with an adhesive film (3) to form a bionic seal. seal.

[0043] As an example, but not to limit the scope of the invention, figure 1 a-d are transfer flow diagrams proposed in the present invention. figure 1 a-b: The stamp is dipped in ink at room temperature, figure 1 c–d printed under thermal load. Only one unit in the stamp is shown in the figure.

[0044] The stamp is first close t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com