Pierced type material receiving device with machine tool material removal function

A splicing device and hollow-out technology, which is applied in the field of hollow-out machine tool material cleaning splicing device, can solve the problems of inability to discharge waste, scratches, and waste falling on the surface of the splicing mechanism, etc., to ensure smoothness, Accurately detect the effect of increasing kinetic energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022]The present invention will be described in further detail below by means of specific embodiments:

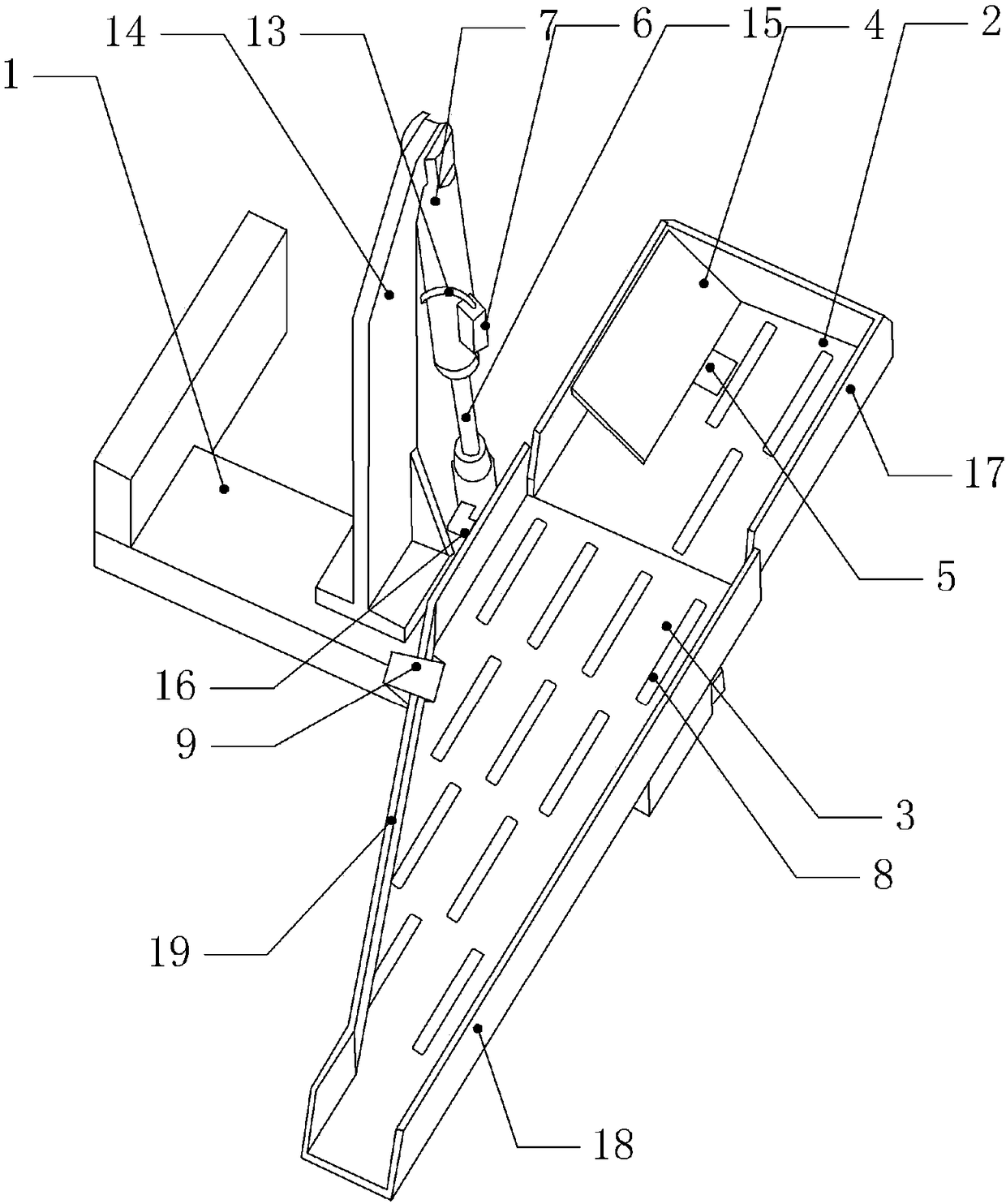

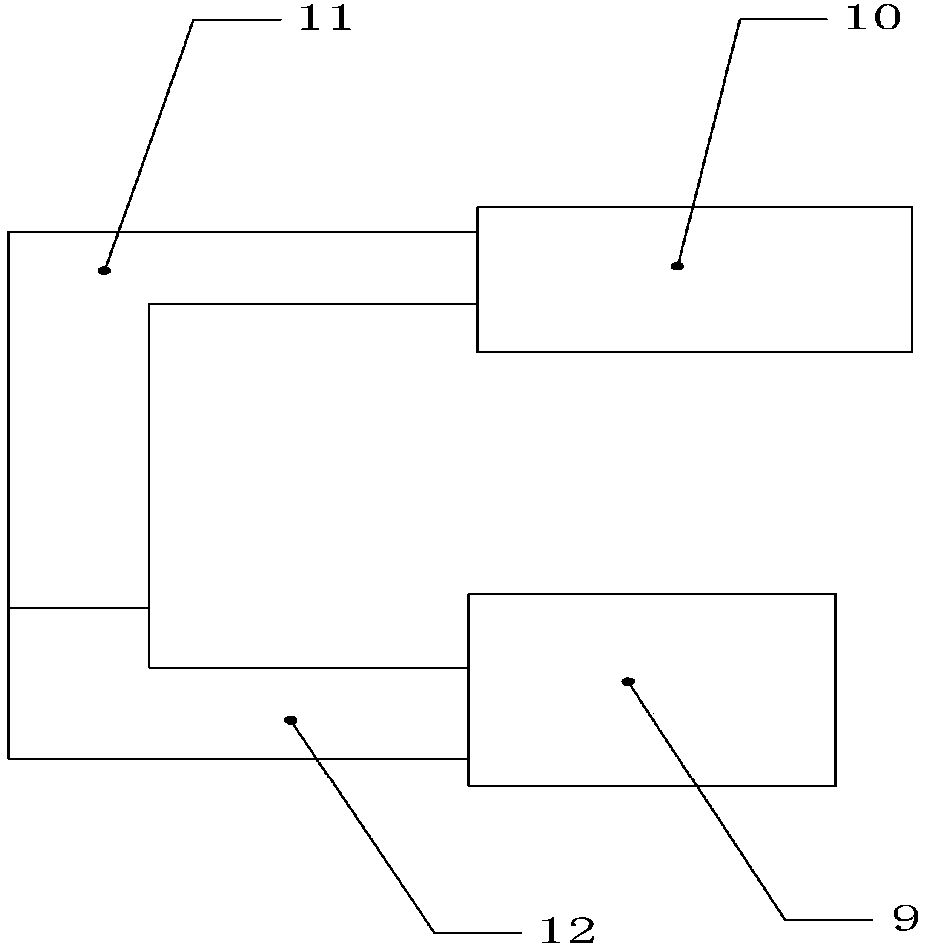

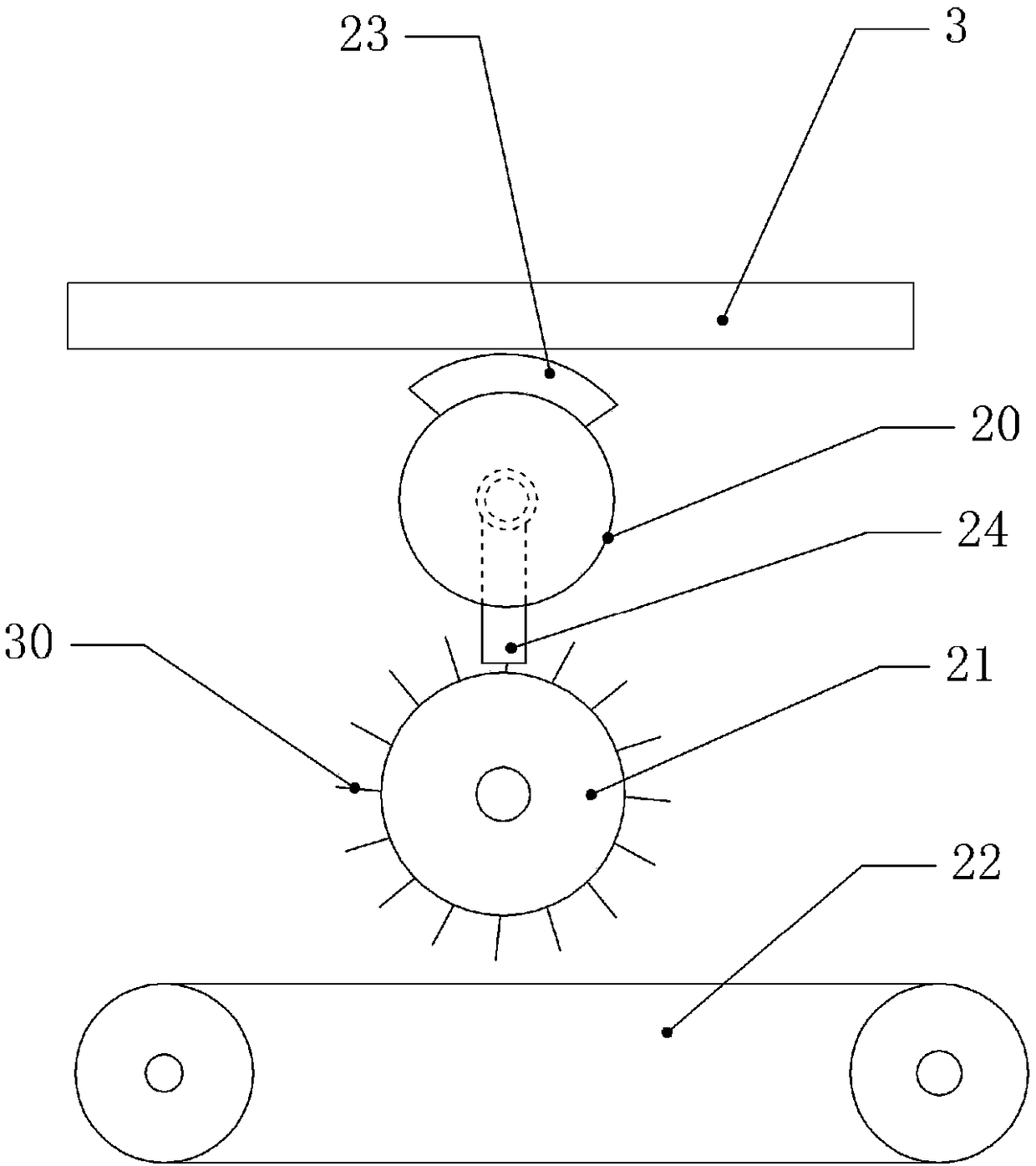

[0023] The reference signs in the drawings of the description include: fixed frame 1, rotary receiving tray 2, fixed receiving tray 3, guide plate 4, pressure sensor 5, first air pump 6, pushing cylinder 7, chip removal hole 8, second An air spray head 9, the second air pump 10, the second air pipe 11, the second flexible pipe 12, the first air pipe 13, the first support rod 14, the first piston rod 15, the second support rod 16, the first vertical plate 17, The second vertical plate 18, the third vertical plate 19, the first turntable 20, the second turntable 21, the transmission mechanism 22, the magnet 23, the second air spray head 24, the first rotating shaft 25, the fixed pipe 26, the third support rod 27 , ventilation cavity 28, first hose 29, bristles 30, first incomplete gear 31, second incomplete gear 32, bump 33, drive rod 34, second rotating shaft 35, first moto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com