Preparation method of composite photocatalytic material of Fe3O4-N doped with Ni/Zn-MOFs/g-C3N4

A composite photocatalysis, fe3o4-n technology, applied in the field of photocatalysis, can solve the problems of low utilization rate of light energy, wide band gap, etc., and achieve the effect of high photocatalytic activity, low cost, and simple and easy control of the reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

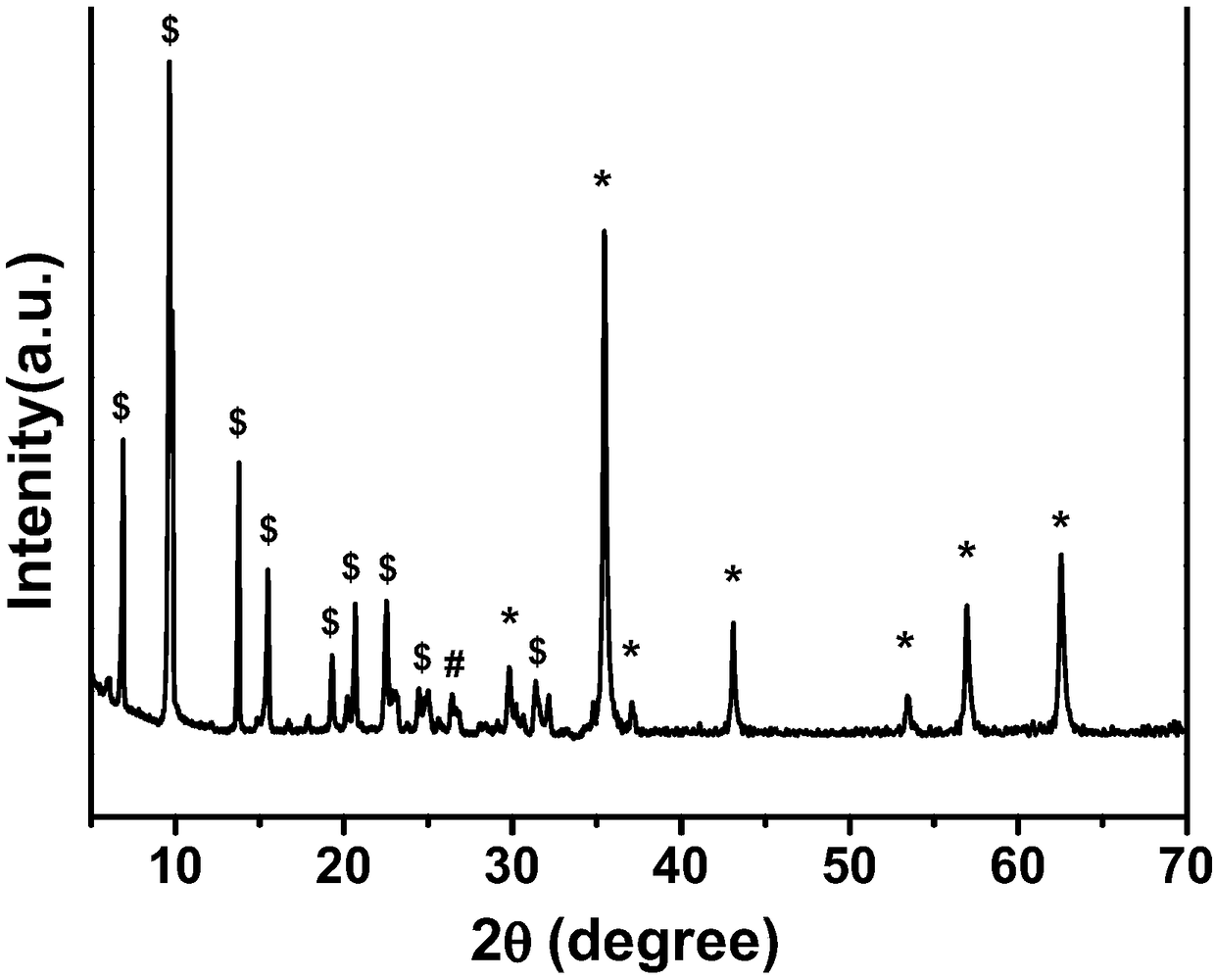

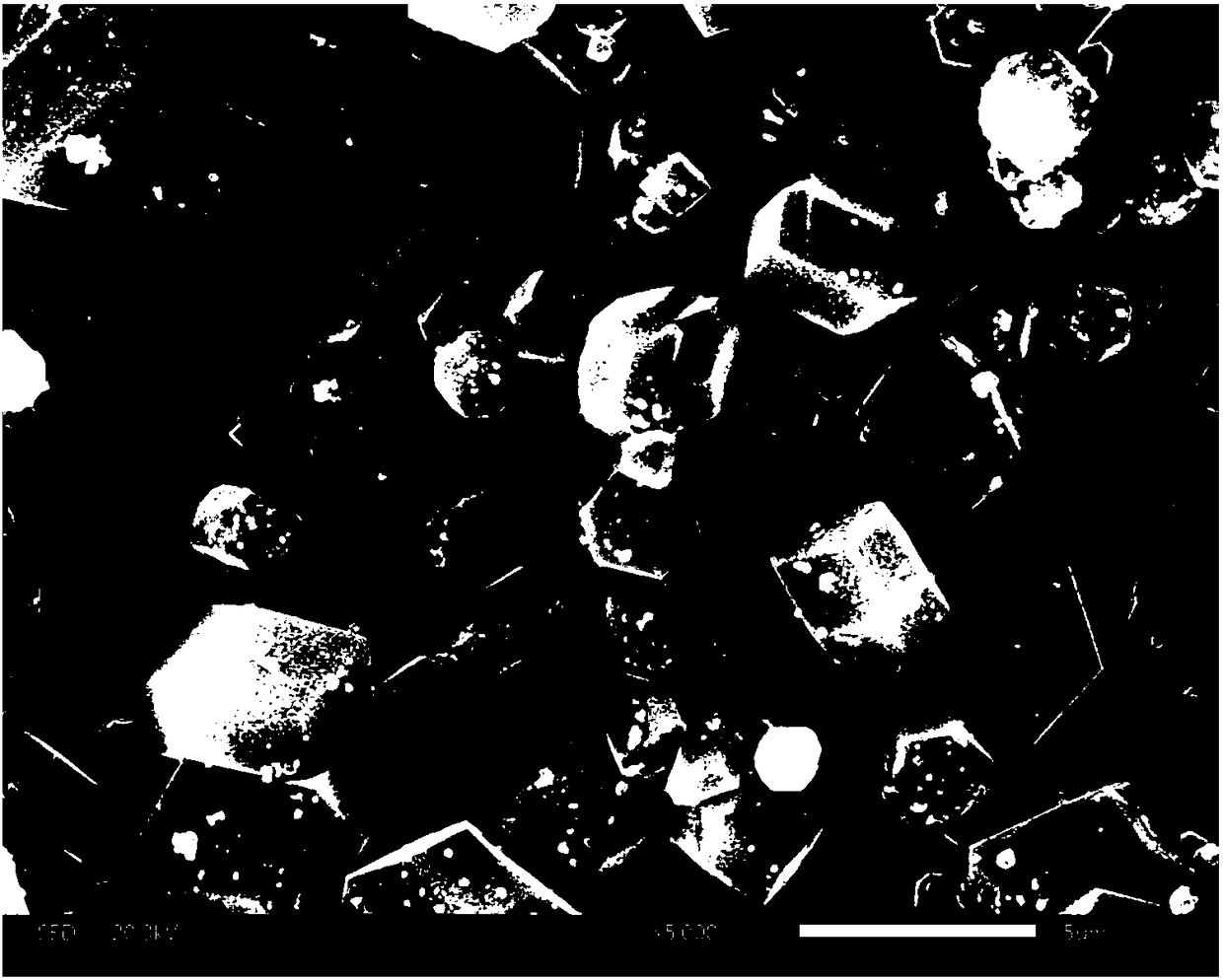

[0026] porous nano Fe 3 o 4 -N-doped Ni / Zn-MOFs / g-C 3 N 4 Composite photocatalytic materials (Fe 3 o 4 / N-Ni / Zn-MOFs / g-C 3 N 4 ) is prepared as follows:

[0027] Step S1, put the urea in the crucible, cover it, and roast it in a muffle furnace at a constant temperature of 550°C for 4h, with a heating rate of 10°C / min, cooling and grinding to obtain g-C 3 N 4 .

[0028] Step S2, FeCl 3 ·6H 2 O, sodium acetate and ethylenediamine are added to ethylene glycol, wherein FeCl 3 ·6H 2 The mass ratio of O, sodium acetate, ethylenediamine and ethylene glycol is 1:4:2:30, ultrasonically dispersed for 30min, and then magnetically stirred for 1h until the solid reactants are completely dissolved; In a stainless steel reaction kettle lined with tetrafluoroethylene, seal the reaction kettle, put the reaction kettle in an oven and heat it up to 200°C for a constant temperature reaction for 6 hours. After the reaction is completed, cool to room temperature, centrifuge to separate...

Embodiment 2

[0032] porous nano Fe 3 o 4 -N-doped Ni / Zn-MOFs / g-C 3N 4 Composite photocatalytic materials (Fe 3 o 4 / N-Ni / Zn-MOFs / g-C 3 N 4 ) is prepared as follows:

[0033] Step S1, dissolving urea in ultrapure water in advance, transferring the aqueous solution to a reaction kettle with a Teflon lining, reacting at a constant temperature of 200° C. for 12 hours, then cooling to room temperature, separating solid matter, washing, and drying; Put the dried urea in a crucible, cover it with a lid, and roast it in a muffle furnace at a constant temperature of 550°C for 4 hours, with a heating rate of 10°C / min, cooling and grinding to obtain g-C 3 N 4 .

[0034] Step S2, FeCl 3 ·6H 2 O, sodium acetate and ethylenediamine are added to ethylene glycol, wherein FeCl 3 ·6H 2 The mass ratio of O, sodium acetate, ethylenediamine and ethylene glycol is 1:4:2:30, ultrasonically dispersed for 30min, and then magnetically stirred for 1h until the solid reactants are completely dissolved; ...

Embodiment 3

[0038] porous nano Fe 3 o 4 -N-doped Ni / Zn-MOFs / g-C 3 N 4 Composite photocatalytic materials (Fe 3 o 4 / N-Ni / Zn-MOFs / g-C 3 N 4 ) is prepared as follows:

[0039] Step S1, put the urea in the crucible, cover it, and roast it in a muffle furnace at a constant temperature of 450°C for 4h with a heating rate of 10°C / min, cooling and grinding to obtain g-C 3 N 4 .

[0040] Step S2, FeCl 3 ·6H 2 O, sodium acetate and ethylenediamine are added to ethylene glycol, wherein FeCl 3 ·6H 2 The mass ratio of O, sodium acetate, ethylenediamine and ethylene glycol is 1:4:2:30, ultrasonically dispersed for 30min, and then magnetically stirred for 1h until the solid reactants are completely dissolved; In a tetrafluoroethylene-lined stainless steel reaction kettle, seal the reaction kettle, put the reaction kettle in an oven and heat it up to 180°C for a constant temperature reaction for 7 hours, cool to room temperature after the reaction, centrifuge to separate the solid, and wash...

PUM

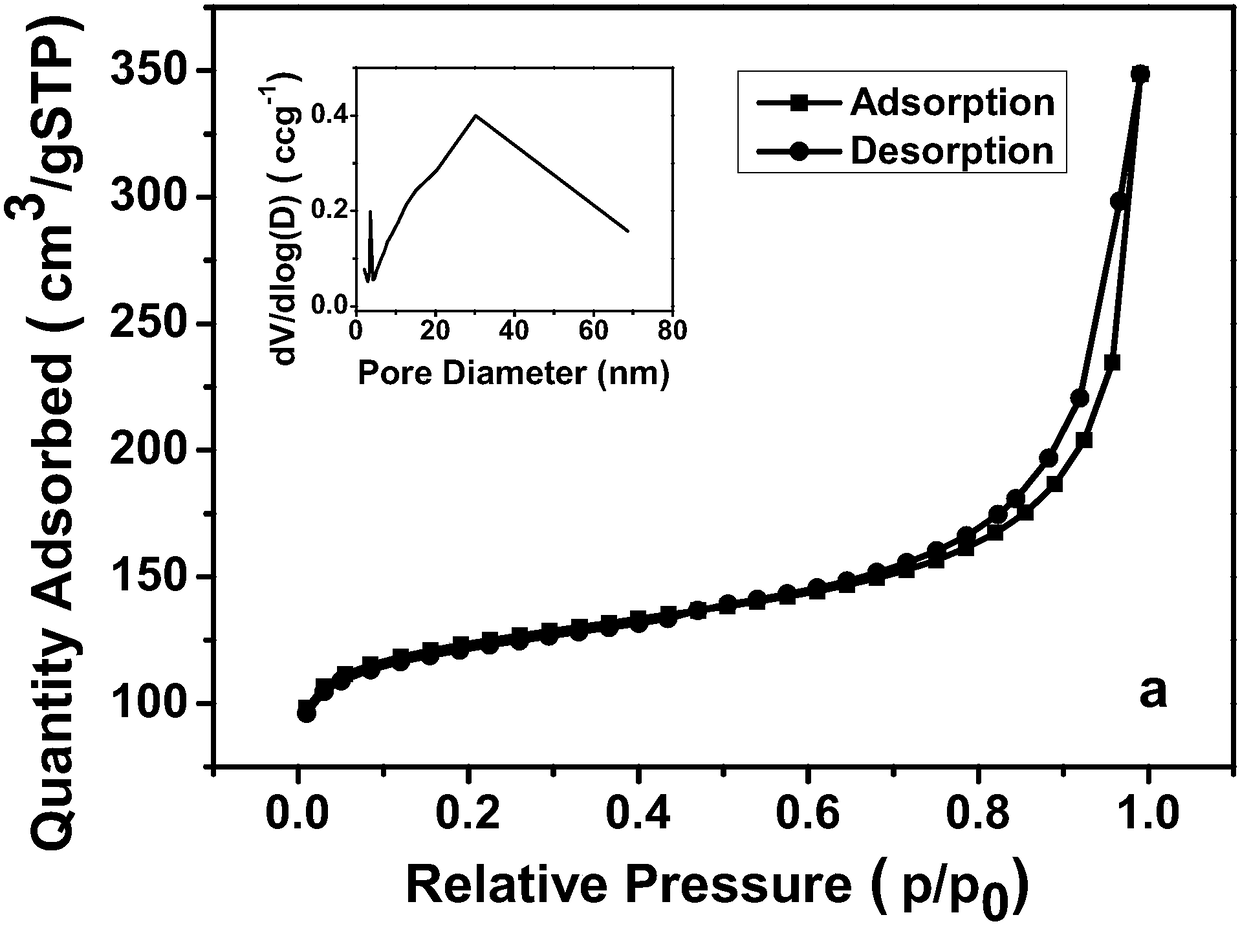

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com