Powder medicament manufacturing method for pharmacy department

A production method and technology of the pharmacy department, applied in the medical field, can solve problems such as affecting patients' rest, easy breakage, loud sound, etc., and achieve the effects of avoiding insufficient grinding, improving grinding efficiency, and preventing accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

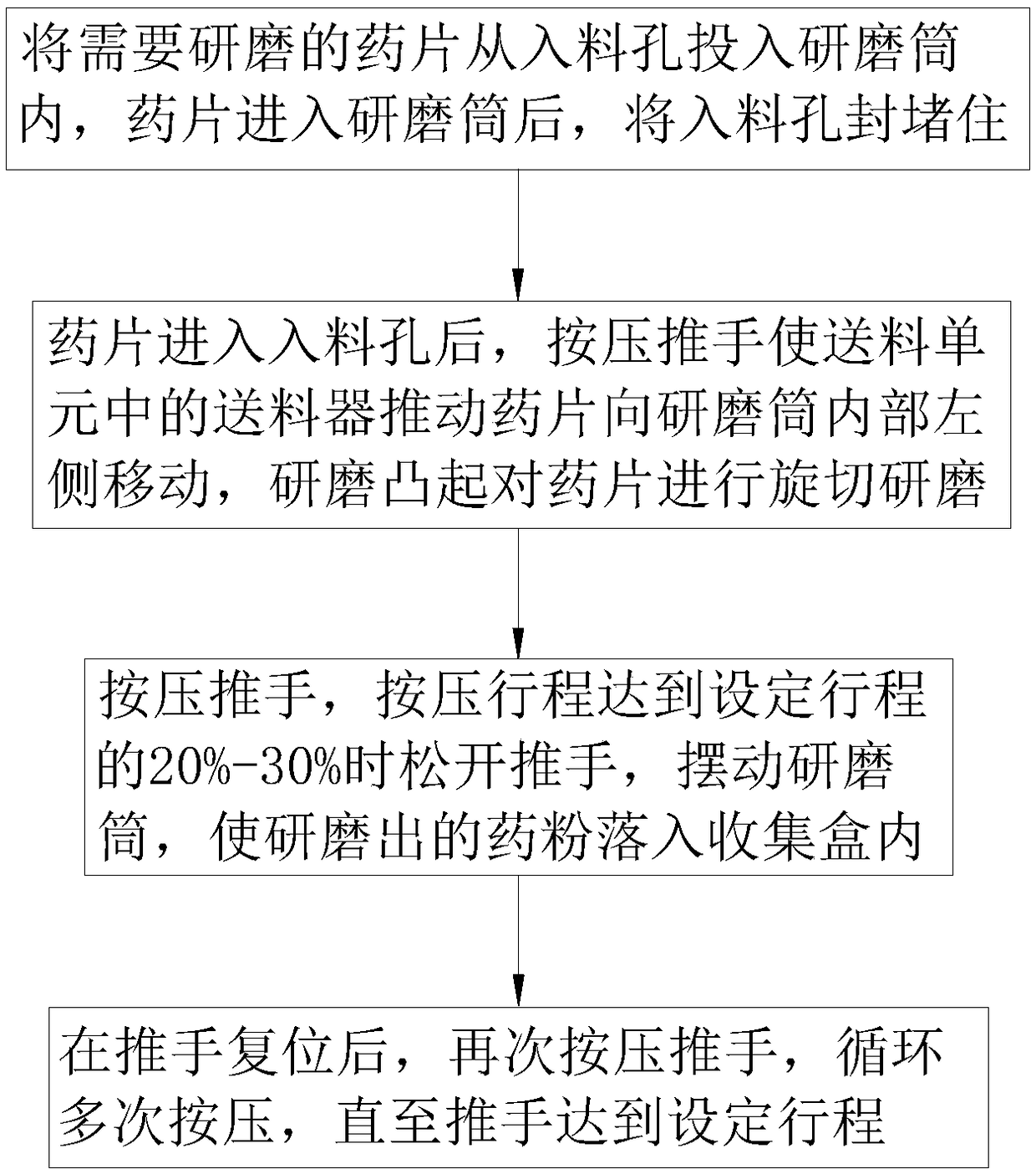

Method used

Image

Examples

Embodiment approach

[0041] As an embodiment of the present invention, a No. 2 groove 16 is provided inside the annular cylinder wall of the grinding cylinder 1, and a cleaning roller 14 and a grinding roller 15 are arranged inside the No. 2 groove 16, and the cleaning roller 14 and the grinding roller 15 are cylinders. body, the cleaning roller 14 and the grinding roller 15 are rotatably installed on the side wall of the No. from 11. When working, the feeder 41 is moved to the left along the grinding barrel 1 by pushing the hand, the feeder 41 pushes the tablet to move, the tablet and the grinding roller 15 rub against each other to make the grinding roller 15 rotate, and the grinding protrusions 11 on the grinding roller 15 grind the tablet At the same time, the grinding projection 11 drives the cleaning roller 14 to rotate through the brush 141, and the brush 141 of the cleaning roller 14 cleans up the residue of medicinal residues on the grinding projection 11 on the grinding roller 15.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com