Fermented feed raw material, preparation method thereof, use thereof and full-price feed comprising the fermented feed raw material

A technology of fermented feed and full-price feed, applied in the forming or processing of animal feed, animal feed, animal feed, etc., can solve the problems of irregular quality control of fermented raw materials, improper operation, failure of fermentation process, etc., to avoid product The effect of unstable quality, non-perishable, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

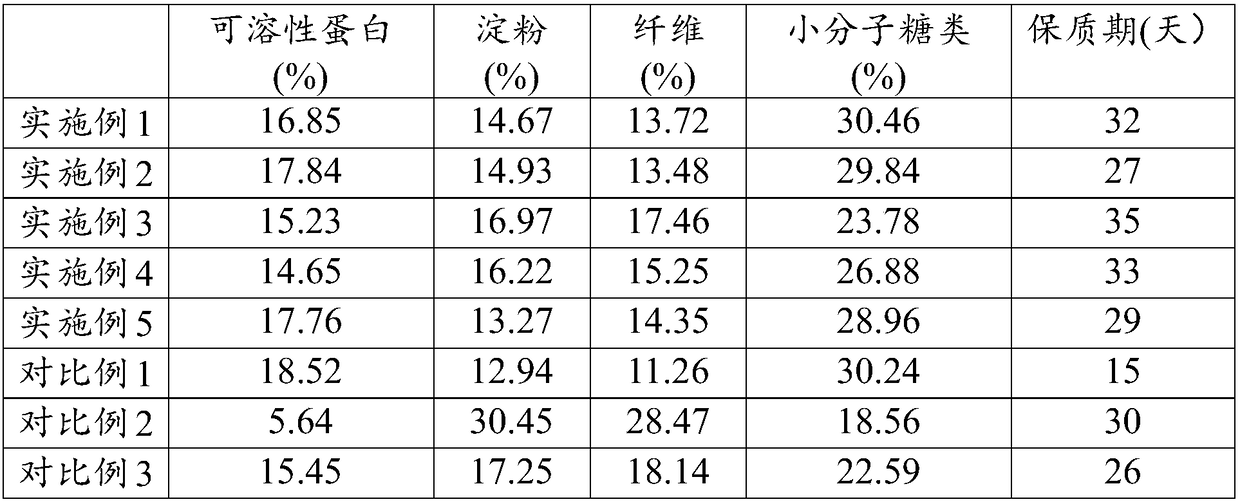

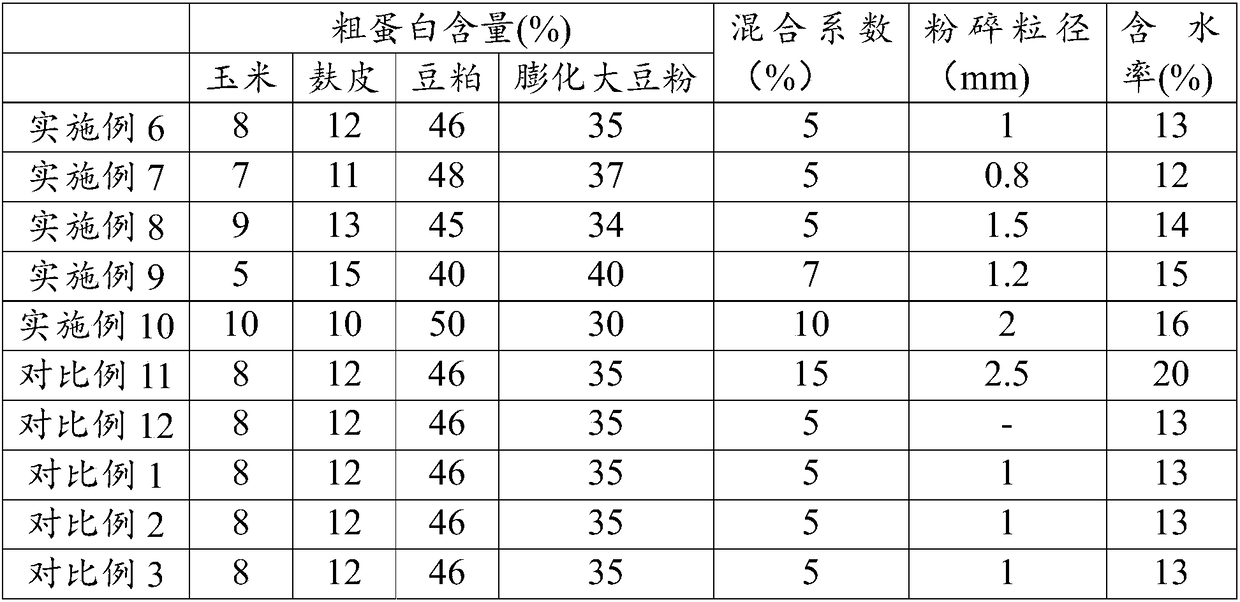

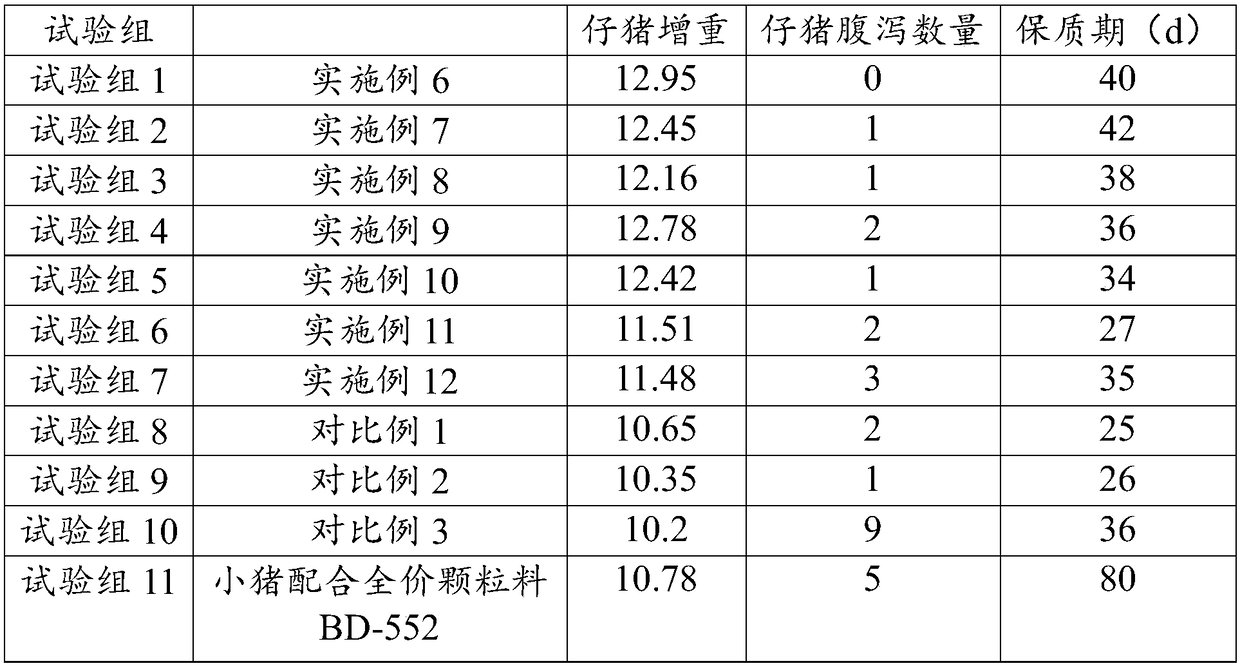

Examples

preparation example Construction

[0060] The raw materials for the preparation of the fermented feed raw materials provided by the invention include complex bacteria and fermentation substrates.

[0061] In some embodiments of the present invention, the composite bacteria include spores, lactic acid bacteria and yeasts; preferably, the composite bacteria include a number ratio of viable bacteria (1-3): (1-3): (1- 3) Bacillus, lactic acid bacteria and yeast, such as but not limited to 3:1:1, 1:3:1, 1:1:3, 2:1:1, 1:2:1, 1: 1:2, 3:1:3, 2:1:2, 3:3:1, or 2:1:3, preferably 1:1:1, can be further optimized by optimizing the ratio of each strain in the composite bacteria Fermentation efficiency and easily absorbed sugar and protein content in fermentation products.

[0062] In some embodiments of the present invention, the fermentation substrate includes corn, soybean meal and corn fiber, optionally, the mass ratio of the corn, soybean meal and corn fiber is (1-3):(1-3): (1-3), for example, but not limited to 3:1:1, ...

Embodiment 1

[0093] The present embodiment provides a kind of fermented feed raw material, comprises following raw material:

[0094] Composite bacteria: spores, lactic acid bacteria and yeast, sucrose molasses and water with a mass ratio of 1:1:1;

[0095] Fermentation substrate: corn, soybean meal and corn fiber with a mass ratio of 1:1:1; the moisture content of corn is 14%, the moisture content of soybean meal is 13%, and the moisture content of corn fiber is 10%.

[0096] The fermentation process is as follows:

[0097] (a) crushing fermentation substrate: crushing corn into 1.2mm particles, soybean meal crushing into 1.3mm particles, and corn fiber crushing into 1.4mm particles;

[0098] (b) Activation of the seed solution: add 4 times warm water to the seed solution to dilute it, add sucrose molasses, and leave it to stand for 4 hours to obtain a composite bacterial solution;

[0099] (c) Get 750 parts by weight of the fermentation substrate, add the compound bacteria liquid to th...

Embodiment 2

[0102] The present embodiment provides a kind of fermented feed raw material, comprises following raw material:

[0103] Composite bacteria: Bacillus, lactic acid bacteria and yeast, sucrose molasses and water with a mass ratio of 2:1:3;

[0104] Fermentation substrate: corn, soybean meal and corn fiber with a mass ratio of 2:3:1; the moisture content of corn is 14%, the moisture content of soybean meal is 13%, and the moisture content of corn fiber is 10%.

[0105] The fermentation process is as follows:

[0106] (a) crushing the fermentation substrate: crushing the corn into 1.0mm particles, crushing the soybean meal into 2.0mm particles, and crushing the corn fiber into 1.5mm particles;

[0107] (b) Activation of the seed solution: add 5 times warm water to the seed solution to dilute it, add sucrose molasses, and let it stand for 5 hours to obtain a composite bacterial solution;

[0108] (c) Get 750 parts by weight of the fermentation substrate, add the compound bacteria...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com