Method for detecting gas forming microorganisms contaminated in milk

A technology of microorganisms and microbial counts, applied in the field of microorganisms, can solve the problems of inability to quickly detect gas-producing microorganisms, qualitative and quantitative characteristics of gas-producing microorganisms, etc., and achieve the effects of low cost, simple operation, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment one: a kind of method that the present invention provides to detect the contaminated gas-producing microorganisms in milk, comprises the following steps:

[0025] (1) Inoculate various gas-producing microorganisms into culture media suitable for their own gas-producing microorganisms, and record the gas production of various gas-producing microorganisms at different times;

[0026] (2) Add the milk samples to be tested in the test tubes of various culture media respectively, and the culture media are the culture media before inoculation in step (1), observe the gas production situation in the test tubes containing various culture media, according to the steps ( 1) The recorded gas production of various gas-producing microorganisms at different times can determine the type of gas-producing microorganisms contaminated in the milk.

[0027] In the present invention, when observing the gas production in the test tubes containing various culture media in the step ...

Embodiment 2

[0037] Embodiment two: a kind of method that the present invention provides detects the contaminated gas-producing microorganism in milk, comprises the following steps:

[0038] (1) Inoculate various gas-producing microorganisms into culture media suitable for their own gas-producing microorganisms, and record the gas production of various gas-producing microorganisms at different times;

[0039] (2) Add the milk samples to be tested in the test tubes of various culture media respectively, and the culture media are the culture media before inoculation in step (1), observe the gas production situation in the test tubes containing various culture media, according to the steps ( 1) The recorded gas production of various gas-producing microorganisms at different times can determine the type of gas-producing microorganisms contaminated in the milk.

[0040] In the present invention, when observing the gas production in the test tubes containing various culture media in the step (2)...

Embodiment 3

[0056] Embodiment 3: This embodiment uses the method of the present invention to detect the types and counts of gas-producing microorganisms in liquid milk systems (pasteurized milk, ultra-high temperature sterilized milk, i.e. UHT milk):

[0057] Inoculate Escherichia coli into two milk systems: pasteurized milk as sample A and UHT milk as sample B;

[0058] Inoculate the yeast into two milk systems: pasteurized milk as sample C and UHT milk as sample D;

[0059] (1) Strain activation

[0060] The initial bacterial liquid was obtained as in Example 2, and the two bacteria were separately inoculated in the two milk systems in different proportions.

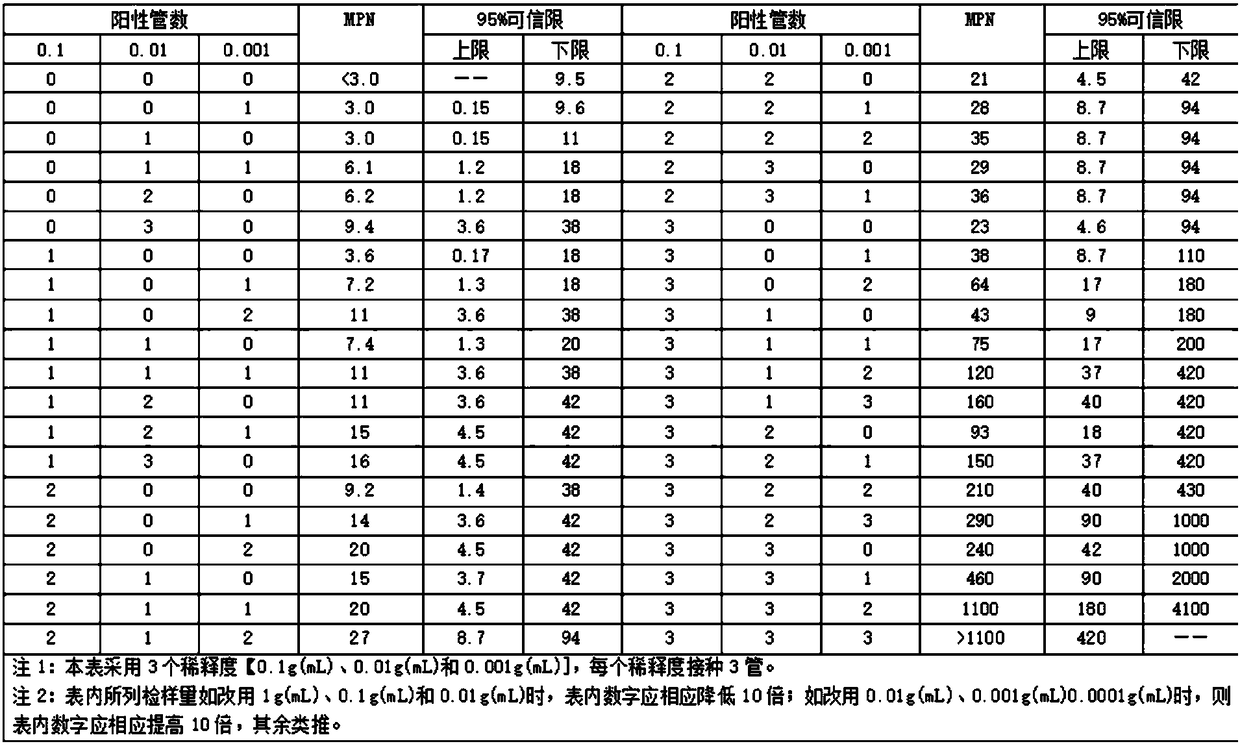

[0061] (2) The sample dilution step is as in Example 1

[0062] (3) Inoculation

[0063] Inoculate the diluted 3 concentration gradient samples into test tubes (10% inoculum size) of the appropriate medium for the corresponding bacterial strains, do 3 parallel experiments for each dilution gradient, control the inoculation time...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com