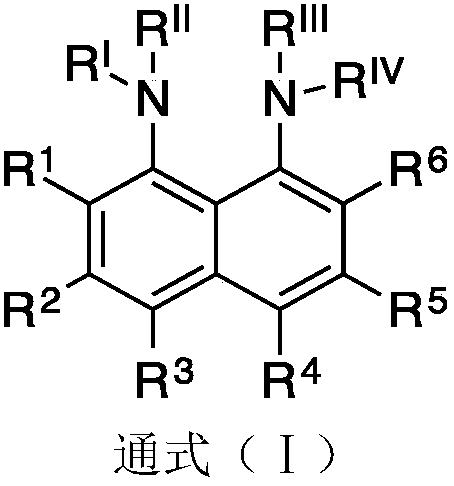

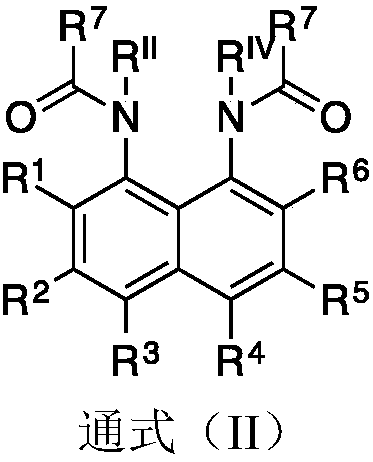

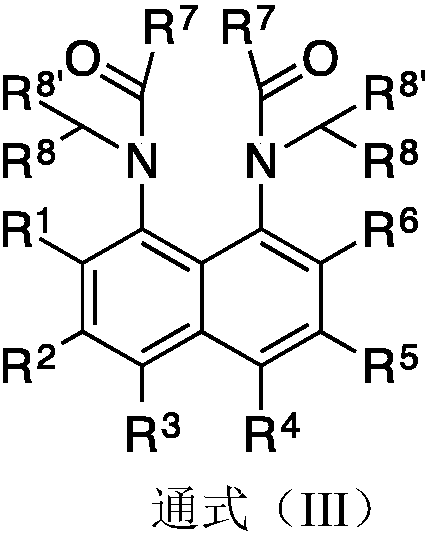

Solid catalyst component containing naphthylenediamine-based compound, and catalyst and applications thereof

A solid catalyst and compound technology are applied to solid catalyst components, catalysts and application fields containing naphthalenediamine compounds, and can solve the problems of unfavorable market promotion, unfavorable development of PP, and high production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0122] Preparation of solid catalyst components

[0123] The operations of preparing catalysts in the examples were all carried out under the protection of high-purity nitrogen. Specific examples are as follows.

Embodiment 1

[0125] In a 500ml stirred 5-neck flask fully replaced by nitrogen, add 10g of diethoxymagnesium and 80mL of toluene to prepare a suspension, and then add 20mL of titanium tetrachloride dropwise at -10°C. After the dropwise addition, the system After slowly raising the temperature to 10°C, 60 mL of titanium tetrachloride was added dropwise, and then slowly raising the temperature to 90°C, adding 4 g of 1,8-diisovalerylamide-naphthalene diamine (A1), and then continuing to heat up to 120°C for 2 hours. Then the liquid was press-filtered clean, the liquid was filtered off, and the obtained solid was washed three times at 125° C. with 120 mL of titanium tetrachloride. The obtained solid was washed twice with 150 mL of hexane at 60°C and twice at room temperature, the liquid was filtered off and dried to obtain a solid powder which was the solid catalyst component. The titanium content, internal electron donor content and polymerization data of the solid catalyst components are sho...

Embodiment 2-27

[0127] The preparation method of the solid catalyst component is the same as in Example 1, except that 1,8-diisovaleramide-naphthalene diamine is replaced by the compounds in Table 1-Table 3 in sequence.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com